Compound insulation formwork for building external wall and construction method of compound insulation formwork

A technology for composite thermal insulation and building exterior walls. It is applied in the direction of formwork/formwork/work frame, thermal insulation, construction, etc. It can solve the problems of difficult thermal insulation performance, low tensile strength and compressive strength, and easy aging. The connection firmness problem, the overall deformation coefficient is small, the effect of good heat preservation and fire prevention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

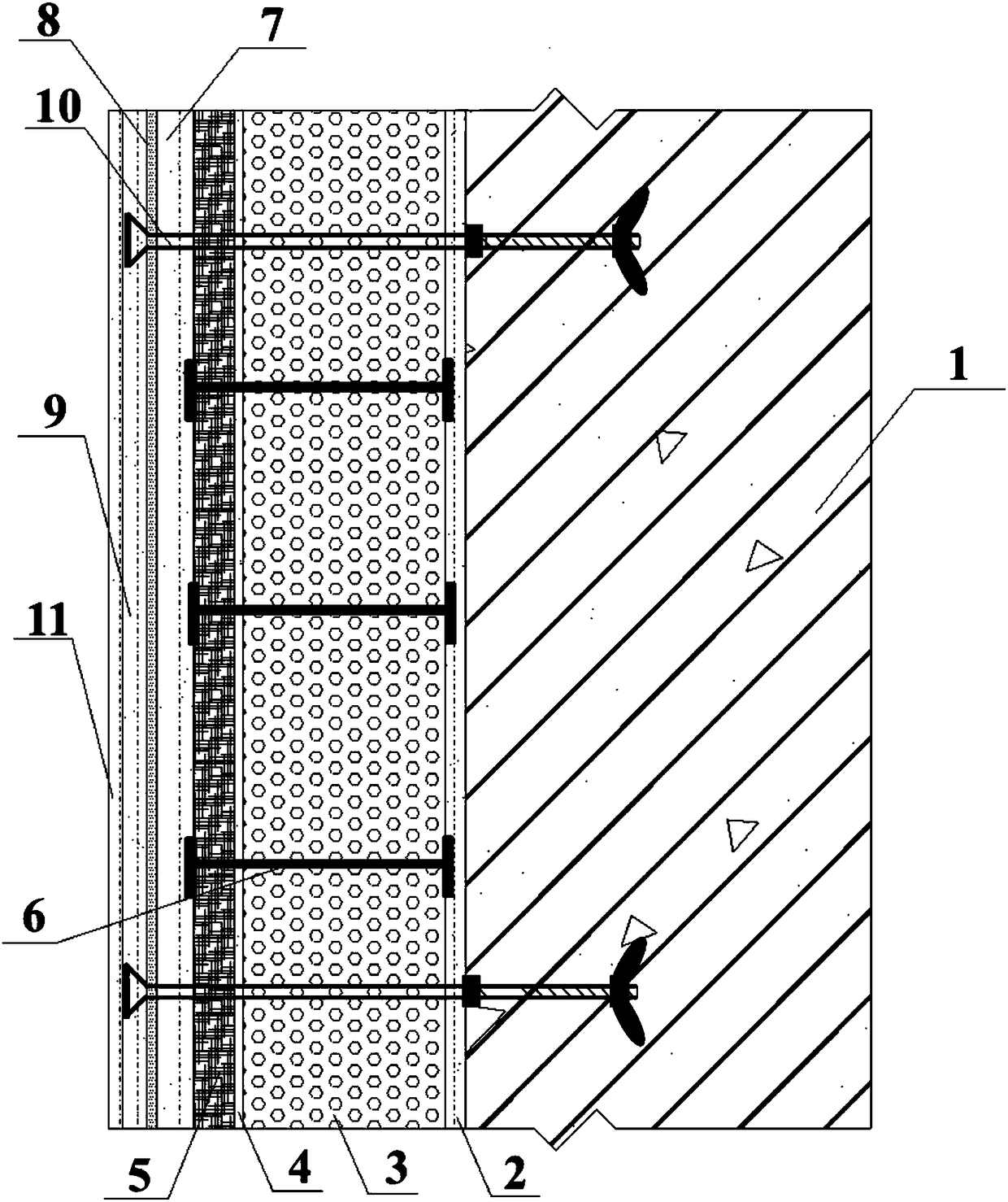

[0031] A composite thermal insulation formwork for building exterior walls, comprising an inner adhesive mortar layer, a silicified polystyrene insulation board, an outer adhesive mortar layer, an airgel fiber felt layer, an insulating mortar layer, and a waterproof layer, leveling mortar layer, anti-cracking mortar layer, of which:

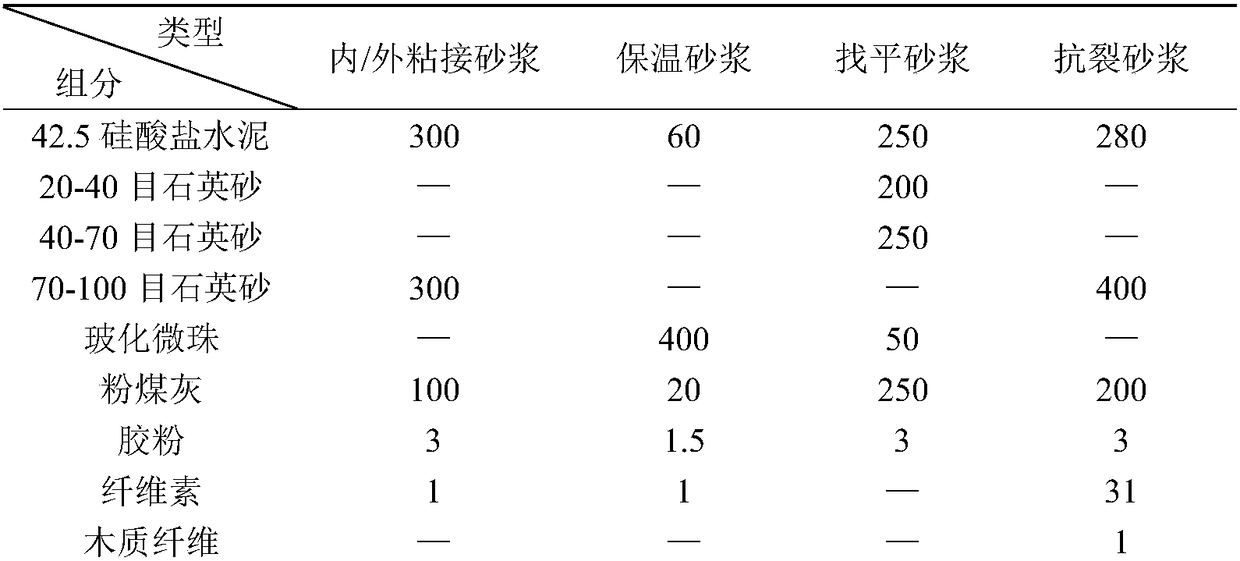

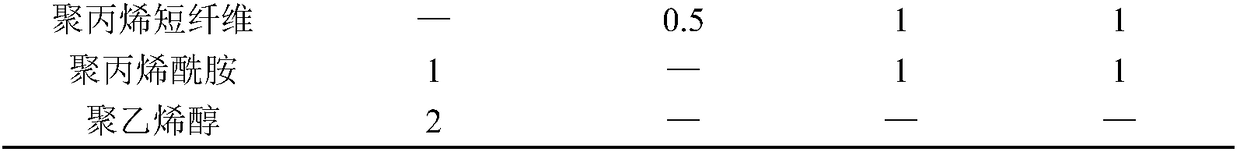

[0032] The inner bonding mortar layer is arranged on the surface of the outer wall substrate, and the composition of the inner bonding mortar layer and the outer bonding mortar layer is shown in the table below (the numbers in the table represent the quality, and the unit is g, the same below). The above-mentioned alkali-resistant mesh cloth is embedded in the middle of the slurry layer formed by mixing Portland cement, quartz sand, fly ash, rubber powder, cellulose, polyacrylamide and polyvinyl alcohol;

[0033] The siliconized polystyrene insulation board is a siliconized polystyrene board, and the siliconized polystyrene board is made by injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com