Novel sodium ion battery positive electrode material and preparation method thereof

A technology for sodium-ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of reducing side reactions, long cycle life, and improving conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this example, raw materials include NaH 2 PO 4 and FeC 2 o 4 , where NaH 2 PO 4 Both a source of sodium and a source of phosphorus, FeC 2 o 4 as iron source, glucose as carbon source, NaH 2 PO 4 and FeC 2 o 4 The molar ratio is 3:2.

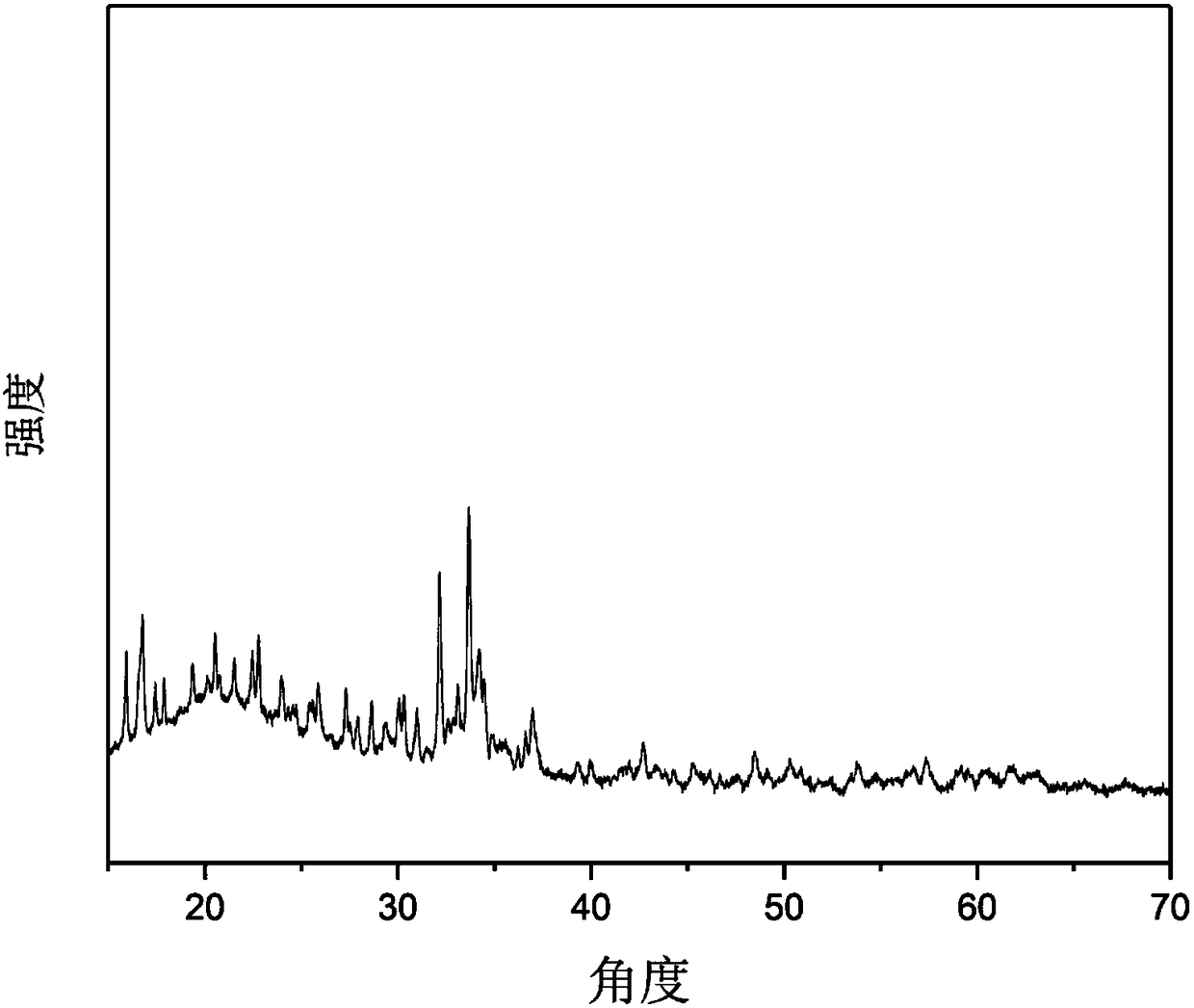

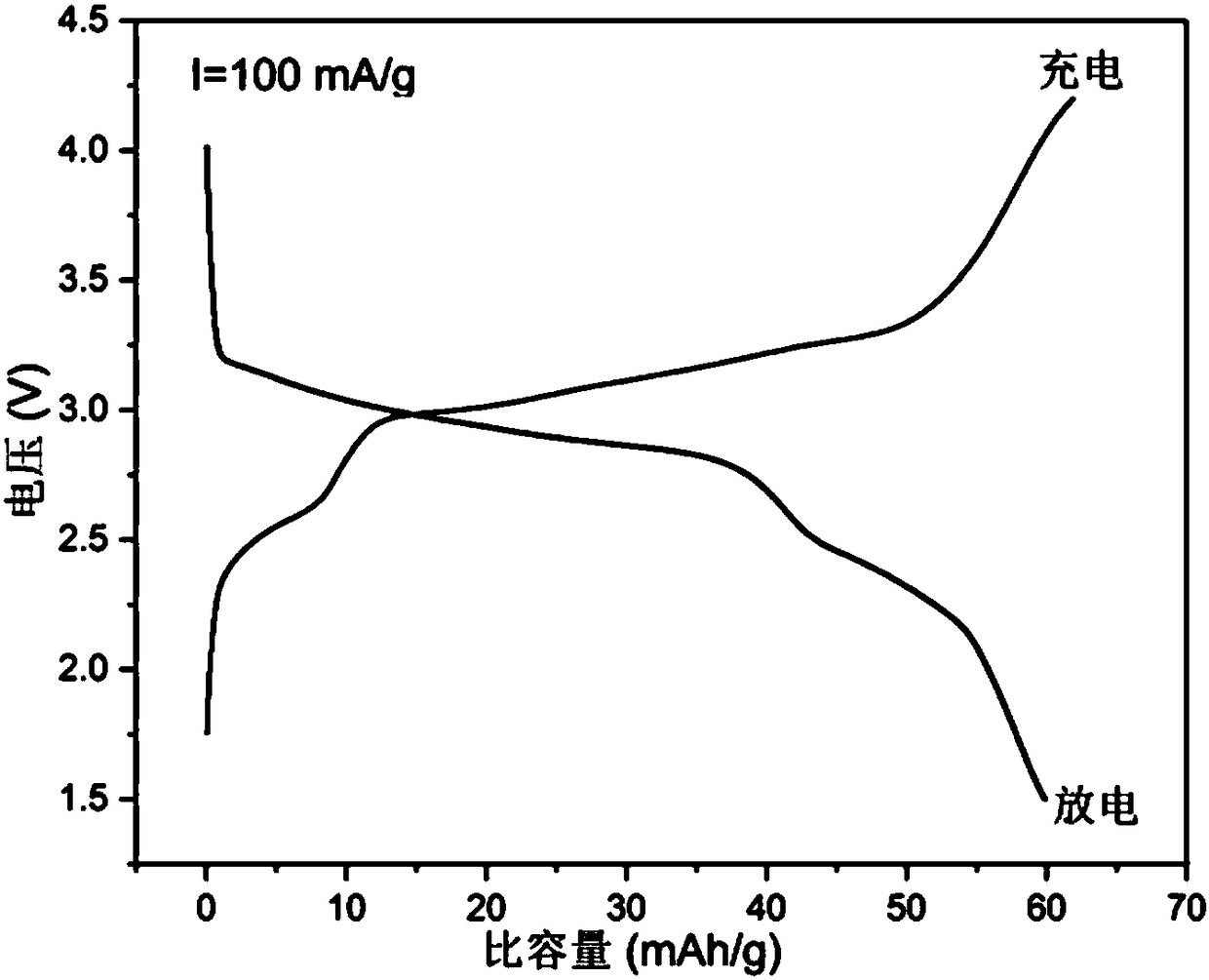

[0032] Using acetone as a dispersant, add acetone and raw materials into a ball mill tank, and perform ball milling in a planetary ball mill to obtain a precursor. The ball milling speed is 400r / min, and the ball milling time is 3h. The precursor was placed in a tube furnace, and under the protection of a high-purity argon atmosphere, the temperature was raised to 250°C at a rate of 1°C / min, and calcined at 250°C for 6 hours to obtain an intermediate product. Grind the intermediate product and press it into a tablet under a pressure of 20MPa to obtain a sheet-shaped intermediate product. Place the sheet-shaped intermediate product in a tube furnace and raise the temperature at a rate of 1°C / min under the protection of a high-pu...

Embodiment 2

[0035] In this example, raw materials include CH 3 COONa, FeC 2 o 4 , NH 4 h 2 PO 4 , (NH 4 ) 4 P 2 o 7 and sucrose, where CH 3 COONa is the sodium source, FeC 2 o 4 as iron source, NH 4 h 2 PO 4 and (NH 4 ) 4 P 2 o 7 as phosphorus source, sucrose as carbon source, CH 3 COONa, FeC 2 o 4 , NH 4 h 2 PO 4 , (NH 4 ) 4 P 2 o 7 The molar ratio is 3:2:1:1.

[0036] Using methanol as a dispersant, add methanol and raw materials into a ball mill tank, and perform ball milling in a planetary ball mill to obtain a precursor. The ball milling speed is 300r / min, and the ball milling time is 4h. The precursor was placed in a tube furnace, under the protection of a high-purity nitrogen atmosphere, the temperature was raised to 300°C at a rate of 2°C / min, and calcined at 300°C for 5h to obtain an intermediate product. Grind the intermediate product, and press it into a tablet under a pressure of 6 MPa to obtain a sheet-shaped intermediate product. The sheet-shaped...

Embodiment 3

[0039] In this example, raw materials include NaH 2 PO 4 , Fe(NO 3 ) 3 and phenolic resins, where NaH 2 PO 4 As both a source of sodium and phosphorus, Fe(NO 3 ) 3 as iron source, phenolic resin as carbon source, NaH 2 PO 4 , Fe(NO 3 ) 3 The molar ratio is 3:2.

[0040] Using ethanol as a dispersant, add ethanol and raw materials into a ball mill tank, and perform ball milling in a planetary ball mill to obtain a precursor. The ball milling speed is 100r / min, and the ball milling time is 6h. The precursor was placed in a tube furnace, and under the protection of a high-purity argon atmosphere, the temperature was raised to 350°C at a rate of 10°C / min, and calcined at 350°C for 4 hours to obtain an intermediate product. Grind the intermediate product and press it into a tablet under a pressure of 4 MPa to obtain a sheet-shaped intermediate product. Place the sheet-shaped intermediate product in a tube furnace and raise the temperature at a rate of 10°C / min under the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com