Carbon fiber surface treatment method and application

A surface treatment and carbon fiber technology, applied in the field of carbon fiber manufacturing, can solve the problems of insufficient comprehensive mechanical properties of composite materials, large amount of waste liquid, and large environmental pollution, achieving excellent mechanical properties, improved production efficiency, and reduced investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

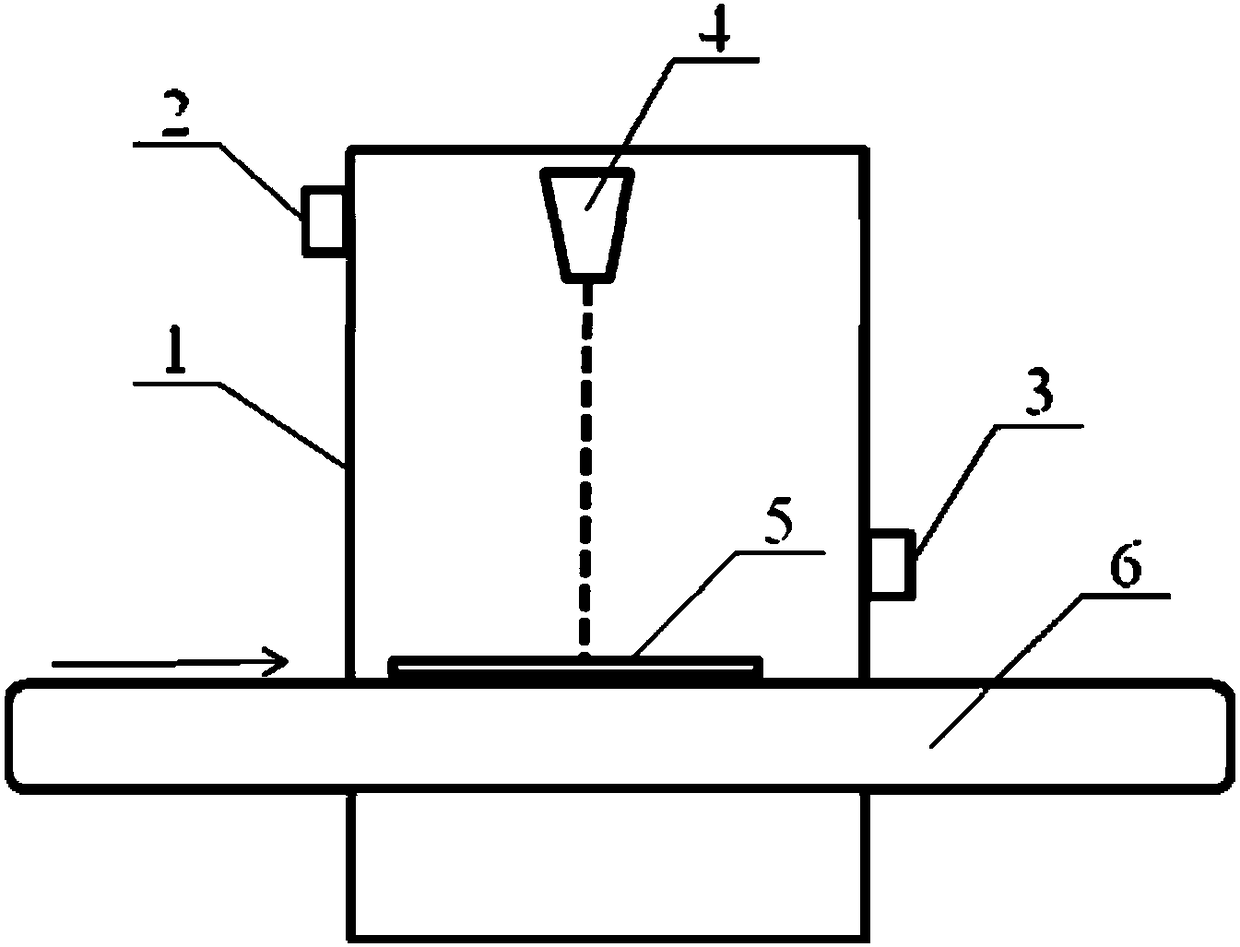

[0037] Get carbon fiber tow (manufactured by Toho Corporation in Japan, model: HTS40), and there is epoxy resin sizing agent on the surface of carbon fiber. Press the carbon fiber asfigure 1 The laser irradiation is set as shown, and the laser irradiation treatment is carried out at room temperature and atmospheric pressure nitrogen atmosphere to obtain the carbon fiber tow after surface treatment. The irradiation conditions are: the wavelength of the laser used is 1064nm (Nd: YAG laser), the irradiation power is 5W, the laser beam focusing radius is 0.05mm, the fiber transmission speed is 0.5m / min, the irradiation dose is 0.05MGy, the laser irradiation speed It is 1000mm / s, and the processing time is 30s.

[0038] The ipa value of the carbon fiber after surface treatment and the oxygen concentration (O / C ratio) on the surface of the carbon fiber were measured, and the results are shown in Table 2.

[0039] Embed carbon fibers in epoxy resin to prepare test pieces. The inter...

Embodiment 2-8

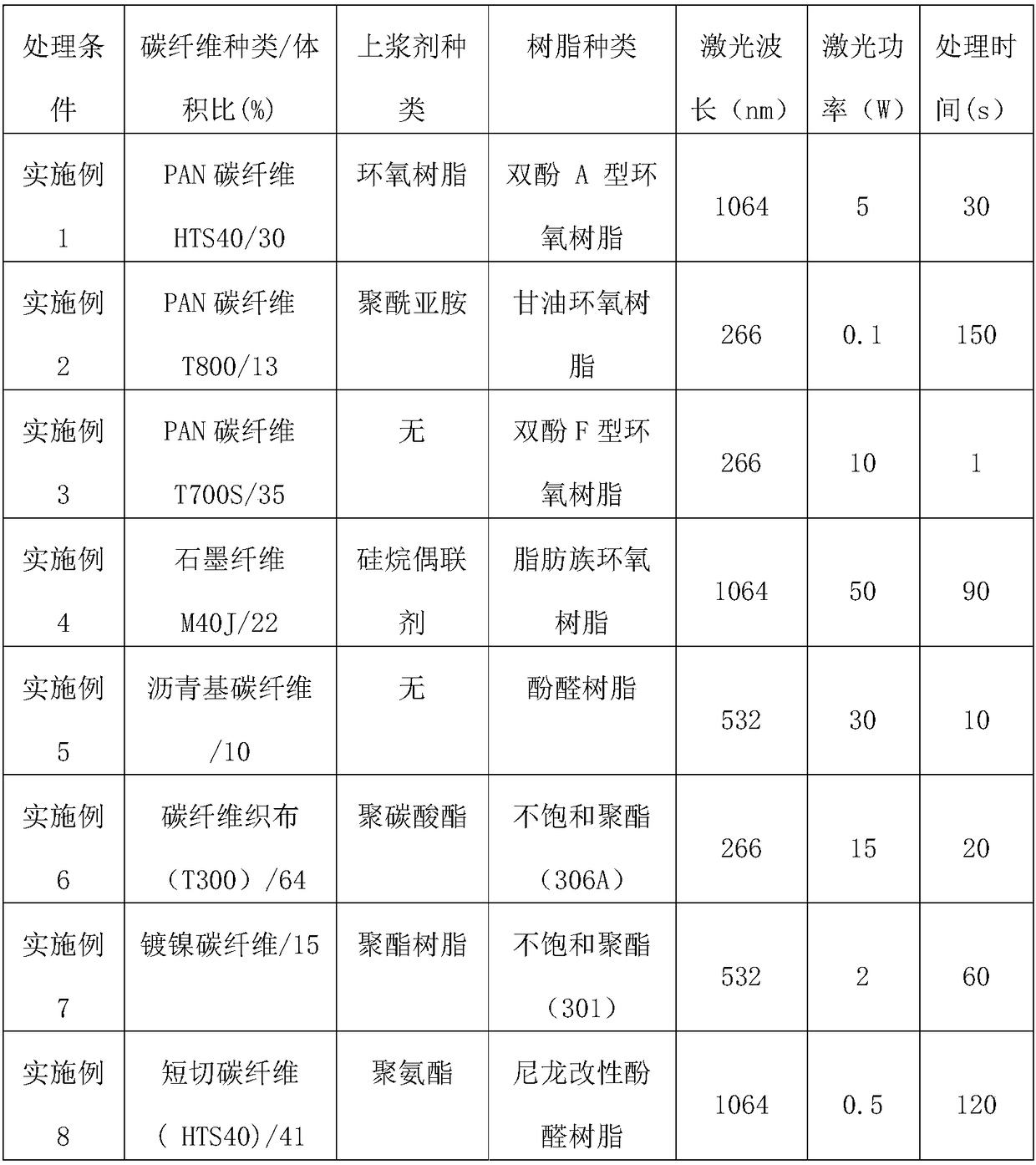

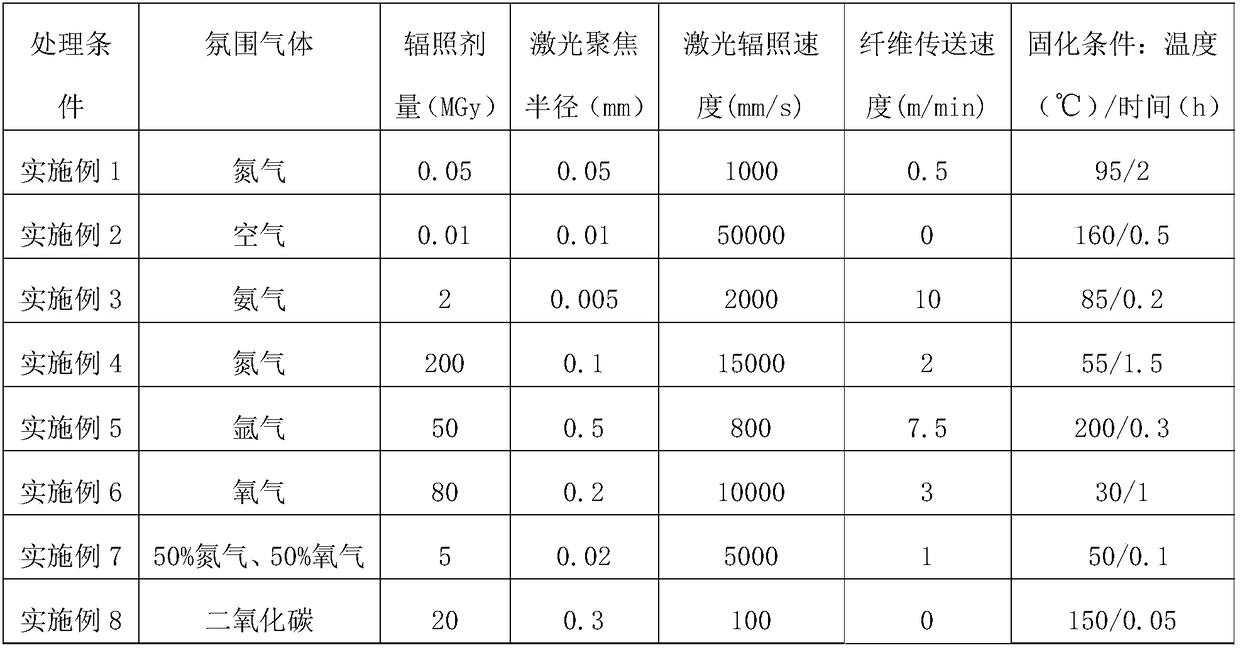

[0042] Change the type and volume fraction of carbon fiber and resin, laser processing power, processing time, atmosphere gas, scanning speed, irradiation dose, irradiation time, fiber transmission speed, laser wavelength, composite molding conditions, and other conditions are the same as in Example 1. The surface treatment of carbon fibers, the specific conditions are shown in Table 1.

[0043] The ipa value and the surface oxygen concentration (O / C ratio) of the above-mentioned surface-treated carbon fibers were measured and calculated, and the results are shown in Table 2. The interfacial shear strength between carbon fiber and epoxy resin was measured according to the single fiber tensile segment crack test method, and the results are shown in Table 2.

[0044] The above-mentioned treated carbon fiber and resin were compounded and cured. After compounding, the composite material was sampled for tensile, bending and impact tests. The test results are shown in Table 2.

[0...

Embodiment 9

[0058] Get carbon fiber tow (HTS40, manufactured by Toho Corporation in Japan), and there is epoxy resin sizing agent on the surface of carbon fiber. Press the carbon fiber as figure 1 The laser irradiation is set as shown, and the laser irradiation treatment is carried out at room temperature and atmospheric pressure nitrogen atmosphere to obtain the carbon fiber tow after surface treatment. The irradiation conditions are: the wavelength of the laser used is 1064nm (Nd: YAG laser), the irradiation power is 5W, the laser beam focusing radius is 0.05mm, the fiber transmission speed is 0.5m / min, the irradiation dose is 0.05MGy, the laser irradiation speed It is 1000mm / s, and the processing time is 30s.

[0059] The ipa value of the carbon fiber after surface treatment and the oxygen concentration (O / C ratio) on the surface of the carbon fiber were measured, and the results are shown in Table 4.

[0060] Carbon fibers were embedded in polyamide 6 resin to prepare test pieces. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com