Rapid molding process method for ointment

A molding process and paste technology, which is applied in the field of component addition, can solve the problems of inability to realize high-precision molding of complex structures and poor precision, and achieve the effects of shortening molding time, small curing shrinkage, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

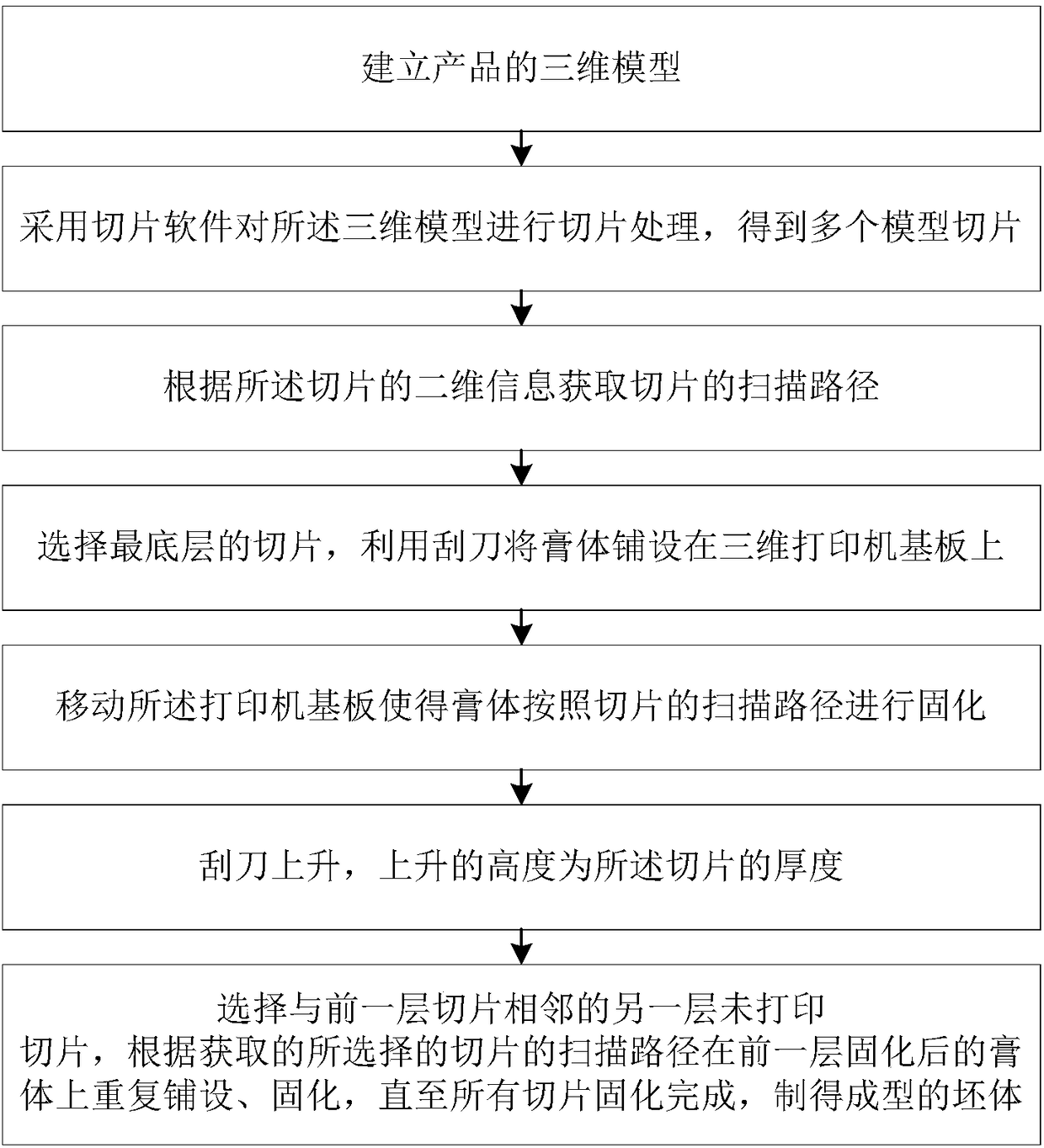

[0035] Such as figure 1 As shown, the embodiment of the present invention provides a rapid prototyping process for paste, comprising the following steps:

[0036] Create a 3D model of the product;

[0037] Slicing the three-dimensional model by using slicing software to obtain a plurality of model slices;

[0038] Acquiring a scan path of the slice according to the two-dimensional information of the slice;

[0039] Select the bottom slice, and lay the paste according to any one of claims 1-6 on the three-dimensional printer substrate with a scraper;

[0040] moving the printer substrate so that the paste is cured according to the scanning path of the slice;

[0041] The scraper rises to a height equal to the thickness of the slice;

[0042] Select another layer of unprinted slices adjacent to the previous layer of slices, and repeat laying and curing on the cured paste of the previous layer according to the scanning path of the selected slices obtained until all the slices...

Embodiment 2

[0051] The present invention provides a kind of paste, and described paste is suitable for the rapid prototyping process of paste, and its raw material composition comprises:

[0052] Paste powder 50%-60%, initiator 0.5%-2%, dispersant 1%-6%, and the rest is photosensitive resin.

[0053] Preferably, the paste is a ceramic paste.

[0054] Preferably, the particle size of the paste powder is 20nm-20um.

[0055] Wherein, the paste powder includes one of alumina, magnesium metatitanate, zinc oxide, zirconia, aluminum nitride, cadmium sulfide or aluminum titanate;

[0056] Preferably, alumina has the characteristics of high strength, high hardness, high toughness, high heat resistance, high insulation, light transmission and biological inertness, and is suitable for integrated circuit substrates, refractory materials, laser components, artificial joints, etc.;

[0057] Preferably, magnesium metatitanate has dielectric properties and is suitable for ceramic capacitors, microwave ...

Embodiment 3

[0066] A preparation method for paste, for preparing paste, comprising:

[0067] Mix the paste raw materials;

[0068] Add the mixed material into the ball mill;

[0069] Ball milling in a ball mill at a speed of 150 rpm to 350 rpm for 2 hours to 10 hours to prepare a paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com