A kind of nickel base self-lubricating composite material and preparation method thereof

A composite material and self-lubricating technology, which is applied in the field of high-strength nickel-based self-lubricating composite materials and its preparation, can solve the problems of composite material porosity affecting mechanical properties, easy agglomeration, poor wettability, etc., and achieve improved activation and sintering effect , Improve the effect of poor wettability and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

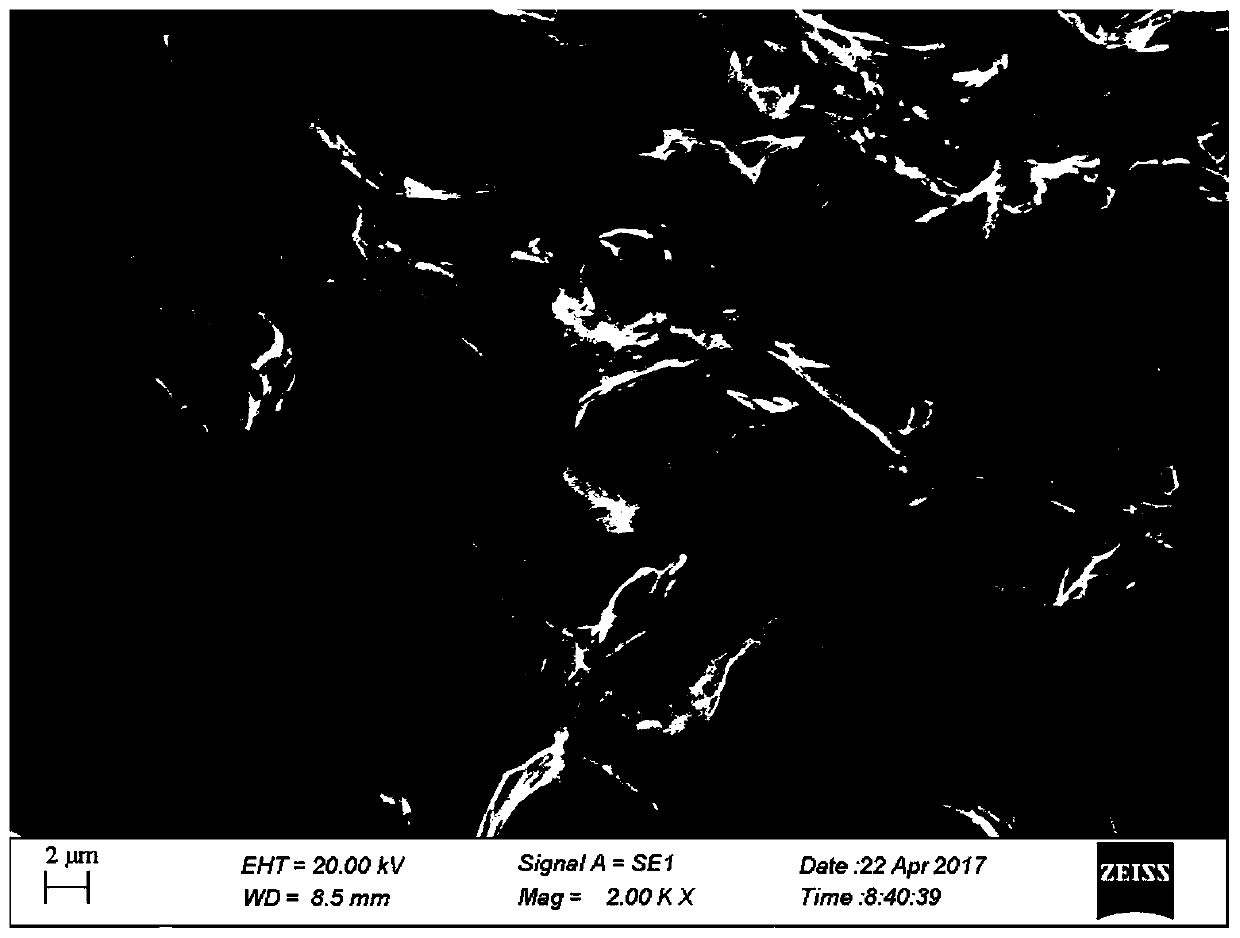

Image

Examples

preparation example Construction

[0034] A preparation method of a nickel-based self-lubricating composite material, comprising the steps of:

[0035] 1) According to the composition of the nickel-based self-lubricating composite material, the raw materials are weighed, wherein the composition of the nickel-based self-lubricating composite material is as described above;

[0036] 2) mixing hexagonal boron nitride and chromium carbide powder, adding modifier, and performing wet ball milling to obtain mixture A;

[0037] 3) The mixture A is heated and roasted under the isolation of oxygen to obtain the modified material B;

[0038] 4) Mix the nickel-based alloy powder with the modified material B, and wet ball mill until uniform, to obtain the mixed material C;

[0039] 5) Press the mixture C into a green body, heat up and sinter under the isolation of oxygen to obtain a sintered body;

[0040] 6) Repress the sintered billet, heat up and refire under the isolation of oxygen, and obtain a nickel-based self-lubr...

Embodiment 1

[0050] A nickel-based self-lubricating composite material, the proportion of which is: V (nickel-based alloy): V (hexagonal boron nitride): V (chromium carbide) = 74:14:12, wherein the mass ratio of nickel-based alloy element powder :W(Ni):W(Cu):W(Fe):W(Mn)=80:8:8:4.

[0051] The preparation method is as follows:

[0052] 1) The hexagonal boron nitride and chromium carbide powders are subjected to wet ball milling on a biaxial rolling machine, wherein the amounts of water and polyacrylamide added are respectively 26% and 1.5% of the total mass of hexagonal boron nitride and chromium carbide, The ball-to-material ratio is 6:1, the ball mill is 42h, and the rotation speed is 80-100rpm, and the mixture A is obtained;

[0053] 2) Put the mixture A into a graphite boat and roast it in a hydrogen atmosphere. The roasting process is as follows: a. Room temperature - 1100°C for 4 hours; b. Heat preservation at 1100°C for 1 hour; c. Cool in the furnace to obtain Modified material B;

...

Embodiment 2

[0059] A high-strength nickel-based self-lubricating composite material, the proportion of which is: V (nickel-based alloy): V (hexagonal boron nitride): V (chromium carbide) = 84:10:6, wherein the nickel-based alloy element powder Mass ratio: W(Ni):W(Cu):W(Fe):W(Mn)=78:6:7:9.

[0060] The preparation method is as follows:

[0061] 1) The hexagonal boron nitride and chromium carbide powders are subjected to wet ball milling on a biaxial rolling machine, wherein the amounts of water and polyacrylamide added are respectively 26% and 1.5% of the total mass of hexagonal boron nitride and chromium carbide, The ball-to-material ratio is 6:1, the ball mill is 42h, and the rotation speed is 80-100rpm, and the mixture A is obtained;

[0062] 2) Put the mixture A into a graphite boat and roast it in a hydrogen atmosphere. The roasting process is as follows: a. Room temperature - 1100°C for 4 hours; b. Heat preservation at 1100°C for 1 hour; c. Cool in the furnace to obtain Modified ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com