Near-infrared fluorescent powder as well preparation method and application thereof

A fluorescent powder and near-infrared technology, which is applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problem that the emission spectrum cannot meet the use requirements, etc., and achieves the convenience of large-scale production and popularization and application, and the preparation time is short , the effect of long excitation wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

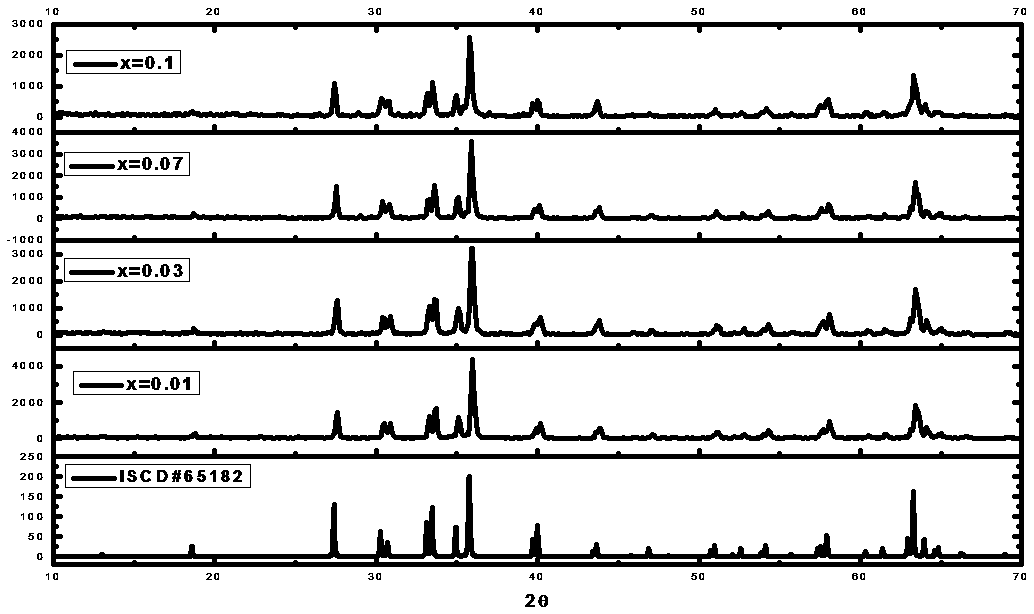

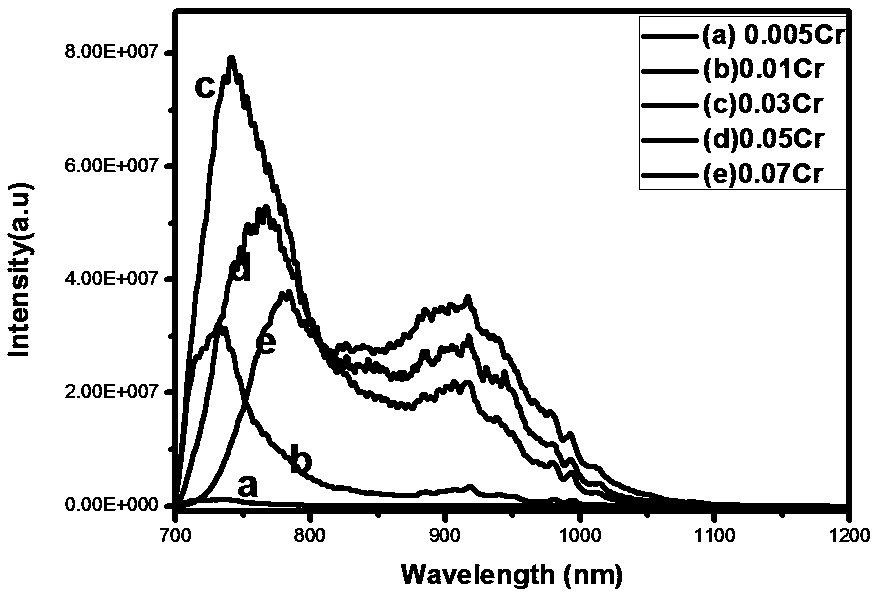

[0025] (1) Weigh the raw materials according to the following weights: Weigh 0.8047g of magnesium oxide (MgO), gallium oxide (Ga 2 O 3 ) 1.2496g, chromium trioxide (Cr 2 O 3 )0.0025g and germanium oxide (Ge 2 O 3 ) 0.6976g, mix evenly, place it in an agate mortar and grind it for 30 minutes to obtain a mixture;

[0026] (2) Place the ground mixture powder in a small crucible, heat up to 1260°C at a heating rate of 5°C / min, sinter at this temperature for 4 hours, and cool to room temperature naturally to obtain a sintered body;

[0027] (3) The obtained sintered body is cooled to room temperature and then fully polished to obtain a chemical formula of Mg 2.995 Ga 2 Cr 0.005 GeO 8 Of near-infrared phosphors.

Embodiment 2

[0029] (1) Weigh the raw materials according to the following weights: Weigh 0.8033g magnesium oxide (MgO), gallium oxide (Ga 2 O 3 ) 1.2496g, chromium trioxide (Cr 2 O 3 ) 0.0051g and germanium oxide (Ge 2 O 3 ) 0.6976g, mix evenly, place it in an agate mortar and grind it for 30 minutes to obtain a mixture;

[0030] (2) Place the ground mixture powder in a small crucible, heat up to 1260°C at a heating rate of 5°C / min, sinter at this temperature for 4 hours, and cool to room temperature naturally to obtain a sintered body;

[0031] (3) The obtained sintered body is cooled to room temperature and then fully polished to obtain a chemical formula of Mg 2.99 Ga 2 Cr 0.01 GeO 8 Of near-infrared phosphors.

Embodiment 3

[0033] (1) Weigh the raw materials according to the following weights: respectively weigh 0.7979g of magnesium oxide (MgO), gallium oxide (Ga 2 O 3 ) 1.2496g, chromium trioxide (Cr 2 O 3 ) 0.0152g and germanium oxide (Ge 2 O 3 ) 0.6976g, mix evenly, place it in an agate mortar and grind it for 30 minutes to obtain a mixture;

[0034] (2) Place the ground mixture powder in a small crucible, heat up to 1260°C at a heating rate of 5°C / min, sinter at this temperature for 4 hours, and cool to room temperature naturally to obtain a sintered body;

[0035] (3) The obtained sintered body is cooled to room temperature and then fully polished to obtain a chemical formula of Mg 2.97 Ga 2 Cr 0.03 GeO 8 Of near-infrared phosphors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com