Solid waste foam concrete and preparation method thereof

A foamed concrete and cementitious material technology, which is applied in the field of engineering materials to achieve the effects of enhancing strength, reducing CO2 emissions and not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

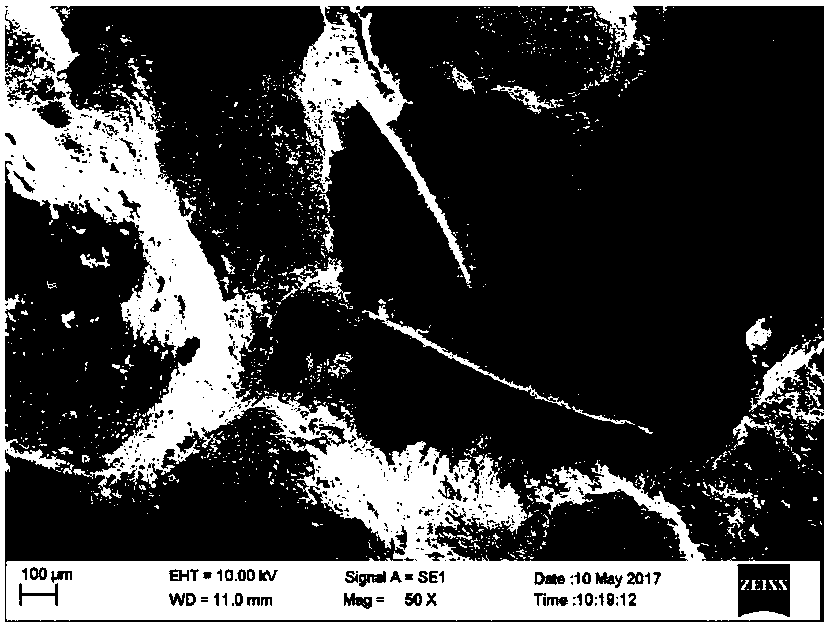

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a cementitious material, and its raw material composition includes 328g of steel slag, 492g of blast furnace water-quenched slag powder, and 180g of desulfurized gypsum.

[0036] The gelling material provided in this embodiment is prepared by the following method:

[0037] Grind 328g steel slag to a specific surface area of 280m2 using a ball mill 2 / kg, and then grind together with 492g blast furnace water-quenched slag powder until the specific surface area is 450m 2 / kg; Take 180g of desulfurized gypsum and mix with the above materials to obtain gelled material.

[0038] The present embodiment also provides a kind of foam concrete, and its raw material composition comprises above-mentioned cementitious material, also comprises 5g superplasticizer, 300g water and 100g foam (the foam utilizes foaming system to active foaming agent animal protein The agent is fully foamed).

[0039] The preparation method of the foamed concrete provided by ...

Embodiment 2

[0042] This embodiment provides a cementitious material, and its raw material composition includes 150g of steel slag, 680g of blast furnace water-quenched slag powder, and 170g of desulfurized gypsum.

[0043] The gelling material provided in this embodiment is prepared by the following method:

[0044] Grind 160g of steel slag with a ball mill until the specific surface area is 300m 2 / kg, and then grind together with 640g blast furnace water-quenched slag powder until the specific surface area is 650m 2 / kg; Take 200g of desulfurized gypsum and mix with the above materials to obtain cementitious materials.

[0045] This embodiment also provides a foam concrete, the raw material composition of which includes the above-mentioned cementitious material, and also includes 8g of high-efficiency water reducer, 250g of water and 150g of foam.

[0046] The foam concrete that present embodiment provides, preparation method is as follows:

[0047]Add 8g of high-efficiency water red...

Embodiment 3

[0049] This embodiment provides a cementitious material, and its raw material composition includes 264g of steel slag, 536g of blast furnace water-quenched slag powder, and 200g of desulfurized gypsum.

[0050] The gelling material provided in this embodiment is prepared by the following method:

[0051] Grind 264g steel slag to a specific surface area of 350m2 using a ball mill 2 / kg, and then grind together with 536g blast furnace water-quenched slag powder until the specific surface area is 700m 2 / kg; Take 200g of desulfurized gypsum and mix with the above materials to obtain cementitious materials.

[0052] This embodiment also provides a foam concrete, the raw material composition of which includes the above-mentioned cementitious material, and also includes 10g of high-efficiency water reducer, 200g of water and 200g of foam.

[0053] The foam concrete that present embodiment provides, preparation method is as follows:

[0054] Add 10g of high-efficiency water redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com