Polyvinyl chloride waterproof coiled material and production technology thereof

A polyvinyl chloride and waterproof membrane technology, which is applied in the field of polymer building waterproof membranes, can solve the problem of unsatisfactory high and low temperature resistance, wear resistance and scratch resistance, which is not conducive to the use of building materials, and speeds up coiling. Improve the anti-biological aging performance, delay the surface migration speed, improve high temperature resistance and fire resistance performance and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

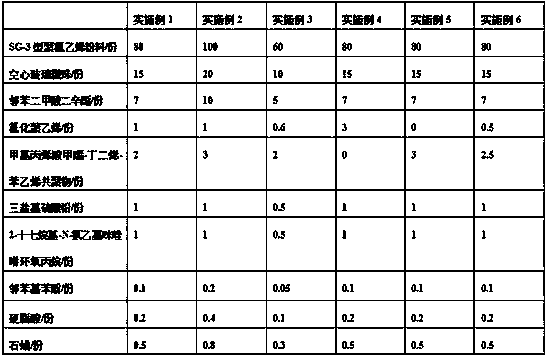

Embodiment 1-6

[0044] Formula is as shown in table 1 in embodiment 1-6, and the preparation technology of embodiment 1-6 is as follows:

[0045] The production process of polyvinyl chloride waterproof membrane, including steps:

[0046] 1) Polyvinyl chloride powder, hollow glass microspheres, plasticizer, impact modifier, stabilizer, stearic acid, paraffin, o-phenylphenol, 2-heptadecyl-N-aminoethyl Add imidazoline propylene oxide into a high-speed mixer for mixing; the mixing temperature is 95°C, and the mixing time is 15 minutes;

[0047] 2) Extrude the powder obtained in step 1) through a twin-screw extruder, and set the temperature of the twin-screw extruder to 170°C;

[0048] 3) Step 2) The extruded material is extruded into a molten state sheet through a T-shaped die, and the temperature of the die is controlled at 185°C;

[0049] 4) The molten state sheet obtained in step 3) is introduced into a three-roll calender for cooling and forming; the temperature of the first roll and the se...

Embodiment 4

[0054]The impact modifier in Example 4 does not include methyl methacrylate-butadiene-styrene copolymer, and the rest are the same as in Example 1.

Embodiment 5

[0055] In embodiment 5, the impact modifier does not include chlorinated polyethylene, and the rest are the same as in embodiment 1.

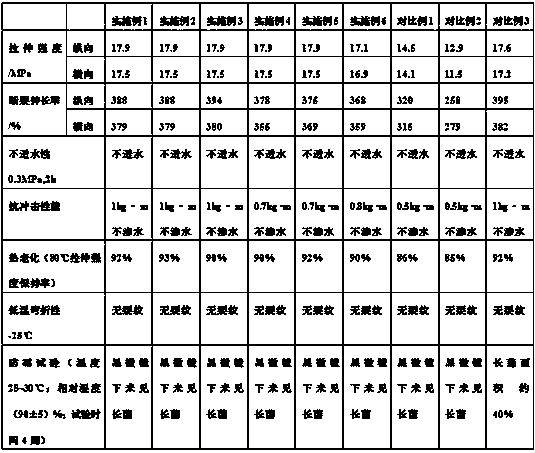

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com