Method for preparing light-weight aromatic hydrocarbon through aromatizing waste edible oil

A technology for discarding edible oil and light aromatic hydrocarbons, which can be applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, and hydrocarbon production by condensation between hydrocarbons and non-hydrocarbons. The problem of high energy consumption is to improve the equilibrium yield of aromatic hydrocarbons, reduce environmental pollution and improve the yield of aromatic hydrocarbons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]1) After preheating the pure waste cooking oil at 350°C, pump it into a fixed bed reactor filled with HZSM-5 molecular sieve catalyst, operate under normal pressure, and operate at a reaction temperature of 500°C and a mass space velocity of 1.20h -1 The reaction is carried out under certain conditions, and it is converted into aromatic hydrocarbon-based products through catalytic conversion;

[0029] 2) The above reaction products are condensed and separated to obtain gas phase products, liquid phase oil phase products and liquid phase water, liquid phase oil phase products are separated by diethylene glycol extraction and distillation to obtain aromatics and non-aromatics, gas phase products and non-aromatic components in the oil phase Return to the reactor to continue the reaction.

Embodiment 2

[0031] 1) Mix the waste cooking oil with water, methanol, ethanol, n-propanol, isopropanol and isobutanol at a ratio of 15% of the waste cooking oil mass concentration, heat and vaporize at 350°C, and then pump it into a container filled with HZSM -5 molecular sieve catalyst in a fixed bed reactor, operated under normal pressure, at a reaction temperature of 500°C and a mass space velocity of 1.20h -1 The reaction is carried out under certain conditions, and it is converted into aromatic hydrocarbon-based products through catalytic conversion;

[0032] 2) The above reaction products are condensed and separated to obtain gas phase products, liquid phase oil phase products and liquid phase water. The liquid phase oil phase products are extracted and distilled through sulfolane to obtain aromatics and non-aromatics. The gas phase products and non-aromatic components in the oil phase are returned to The reactor continues to react.

[0033] The reaction result of embodiment 1 and ...

Embodiment 3

[0038] 1) Mix waste cooking oil and isopropanol at a ratio of 20% waste cooking oil mass concentration, preheat at 400°C and pump them into Molecular sieve catalyst in a fixed-bed reactor, operated under normal pressure, at a reaction temperature of 500°C and a mass space velocity of 1.00h -1 The reaction is carried out under certain conditions, and it is converted into aromatic hydrocarbon-based products through catalytic conversion;

[0039] 2) The above reaction products are condensed and separated to obtain gas phase products, liquid phase oil phase products and liquid phase water, and liquid phase oil phase products are extracted and distilled by N-methylpyrrolidone to obtain aromatic hydrocarbons and non-aromatic hydrocarbons, gas phase products and oil phase The non-aromatic components are returned to the reactor to continue the reaction.

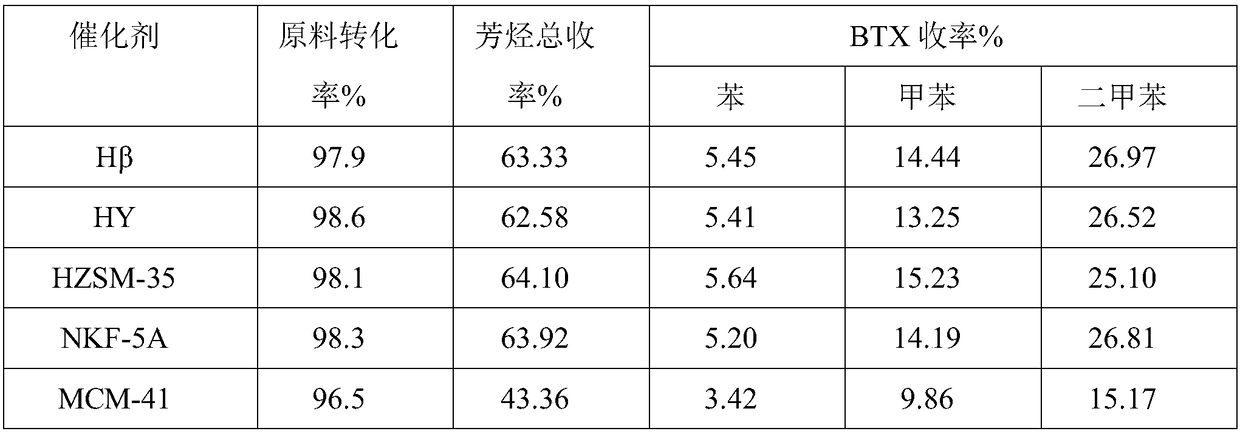

[0040] The reaction results are compared in Table 2.

[0041] Table 2

[0042]

[0043] It can be seen from Table 2 that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com