Welding wire powder, flux-cored wire and preparation and application

A technology of flux-cored welding wire and powder, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of high sensitivity to thermal cracks, welding cracks, restricting the progress of engineering construction, etc., to achieve suitable strength, improve crack resistance, The effect of stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

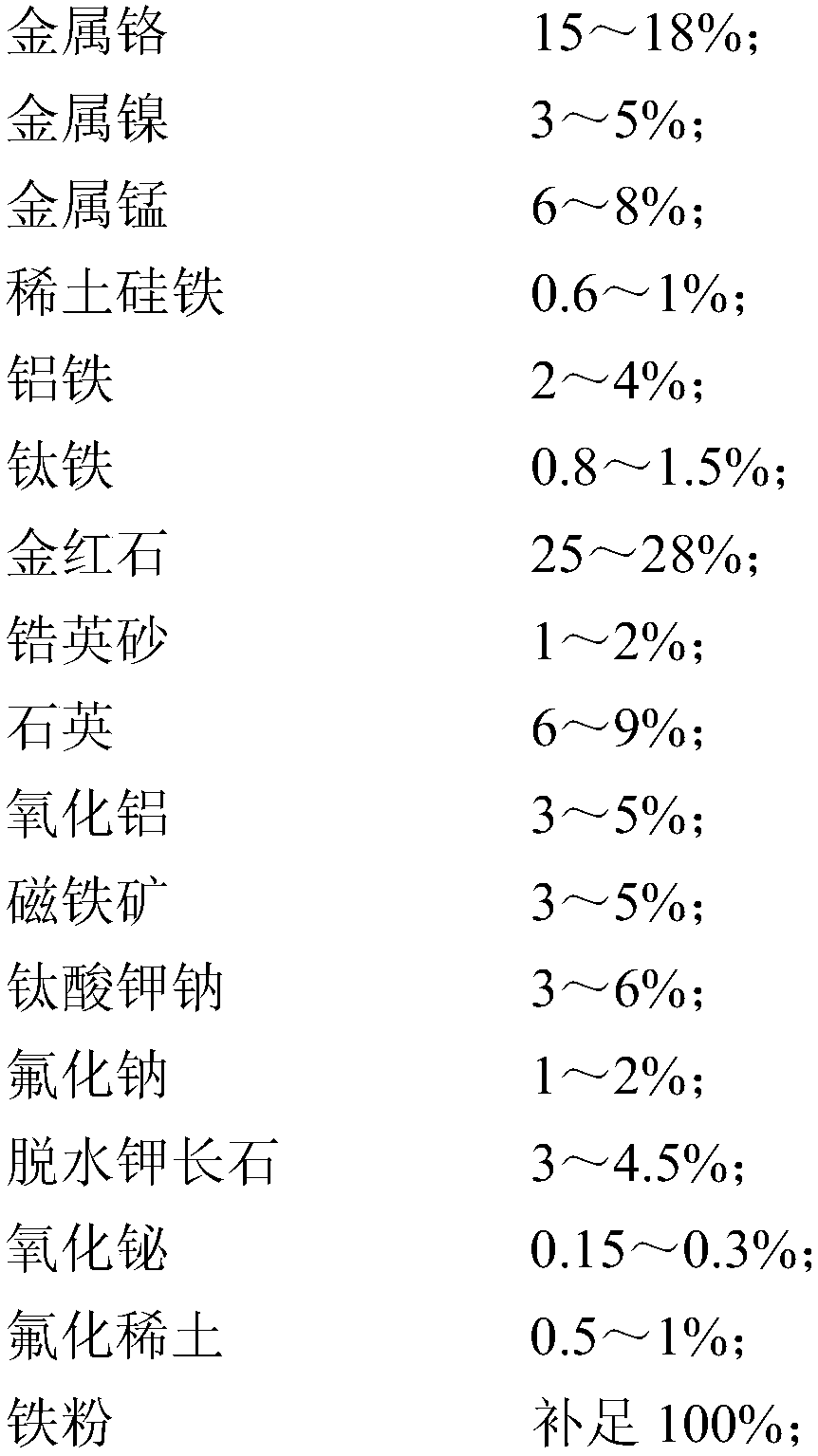

[0067] A welding wire powder, comprising the following components by mass percentage:

[0068]

[0069] A flux-cored welding wire, comprising the above-mentioned welding wire powder and sheath (stainless steel strip);

[0070] The preparation method of the described flux-cored welding wire comprises the following steps:

[0071] (1) Mix the components of the above-mentioned welding wire powder uniformly to obtain the welding wire powder;

[0072] (2) The powder obtained in the step (1) was wrapped with a 304L stainless steel strip and rolled and reduced in diameter to obtain a flux-cored welding wire, wherein the filling rate of the powder was 25wt%, and the diameter of the flux-cored wire was 1.2mm.

Embodiment 2

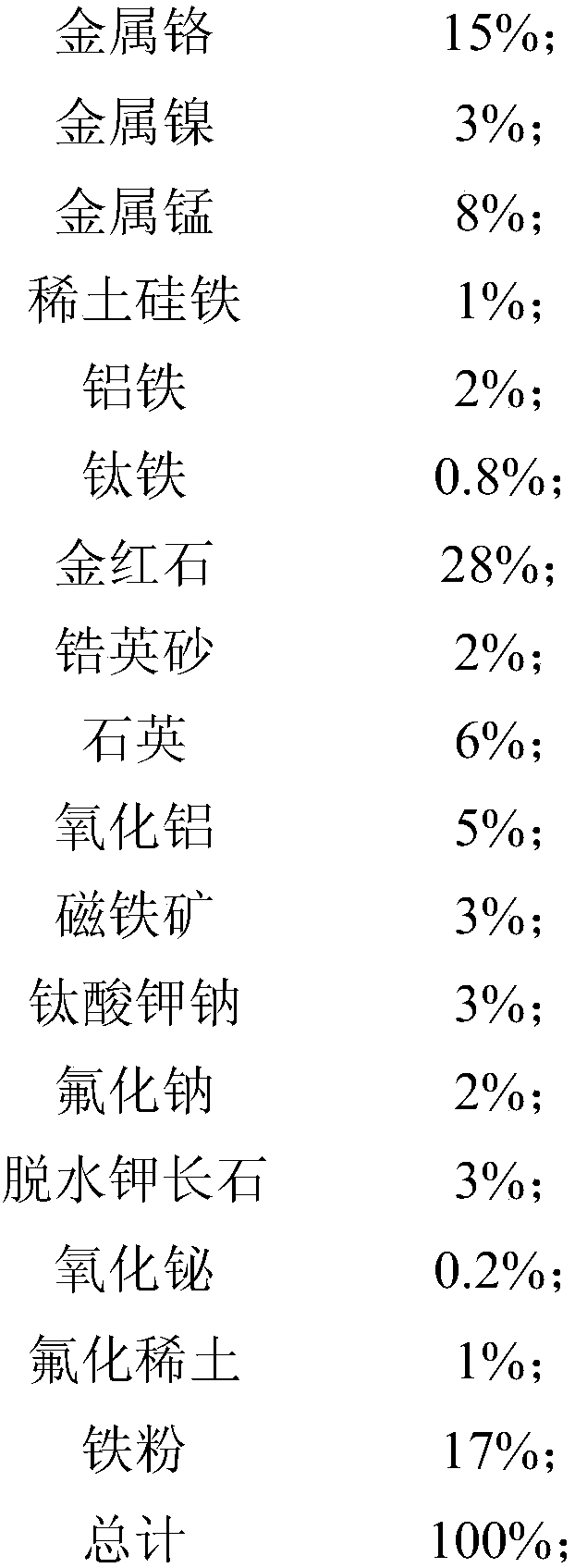

[0074] A welding wire powder, comprising the following components by mass percentage:

[0075]

[0076] A flux-cored welding wire, comprising the above-mentioned welding wire powder and sheath (stainless steel strip);

[0077] The preparation method of the described flux-cored welding wire comprises the following steps:

[0078] (1) Mix the components of the above-mentioned welding wire powder uniformly to obtain the welding wire powder;

[0079] (2) The powder obtained in the step (1) was wrapped with a 304L stainless steel strip, rolled and reduced in diameter to obtain a flux-cored welding wire, wherein the filling rate of the powder was 23.5wt%, and the diameter of the flux-cored wire was 1.2mm.

Embodiment 3

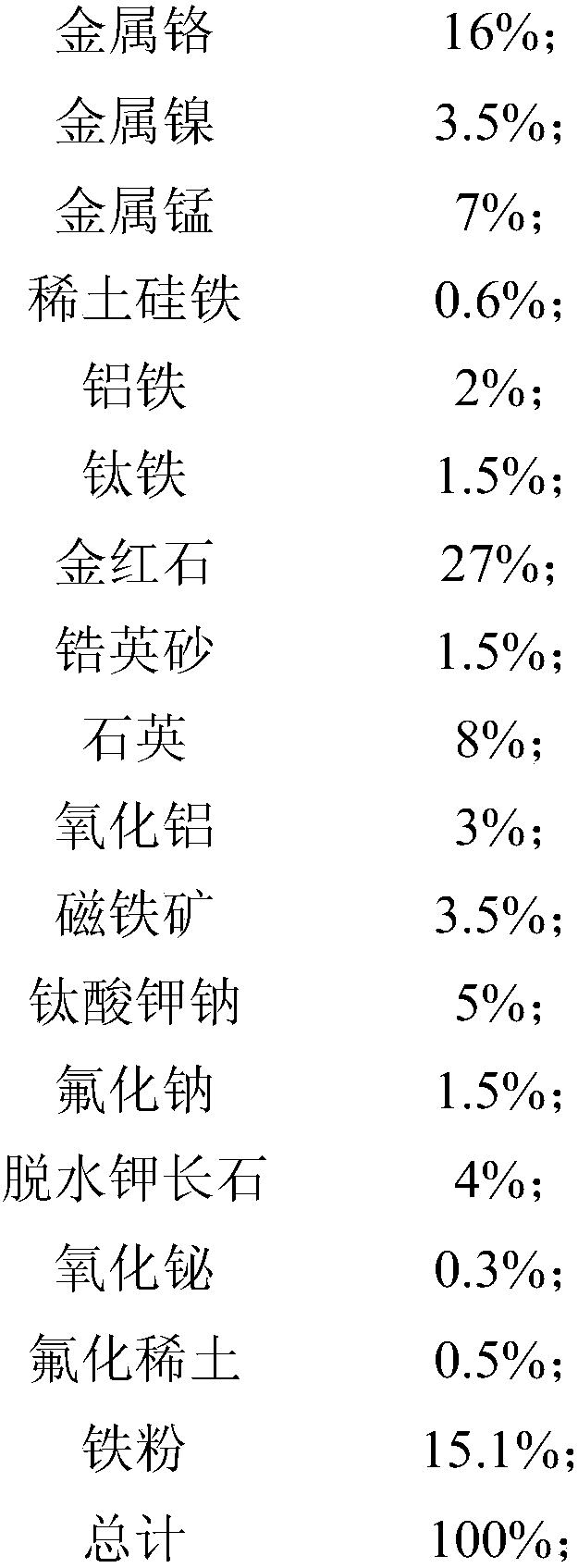

[0081] A welding wire powder, comprising the following components by mass percentage:

[0082]

[0083]

[0084] A flux-cored welding wire, comprising the above-mentioned welding wire powder and sheath (stainless steel strip);

[0085] The preparation method of the described flux-cored welding wire comprises the following steps:

[0086] (1) Mix the components of the above-mentioned welding wire powder uniformly to obtain the welding wire powder;

[0087] (2) The powder obtained in the step (1) was wrapped with a 304L stainless steel strip, rolled and reduced in diameter to obtain a flux-cored welding wire, wherein the filling rate of the powder was 21wt%, and the diameter of the flux-cored wire was 1.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com