Lightweight wood plastic foam board and preparation method thereof

A wood-plastic foaming, lightweight technology, applied in the field of wood-plastic board manufacturing, can solve the problems of reduced practical performance of finished wood-plastic boards, affecting product appearance and sales, poor mechanical properties, etc., to improve production efficiency and production quality, Good consistency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

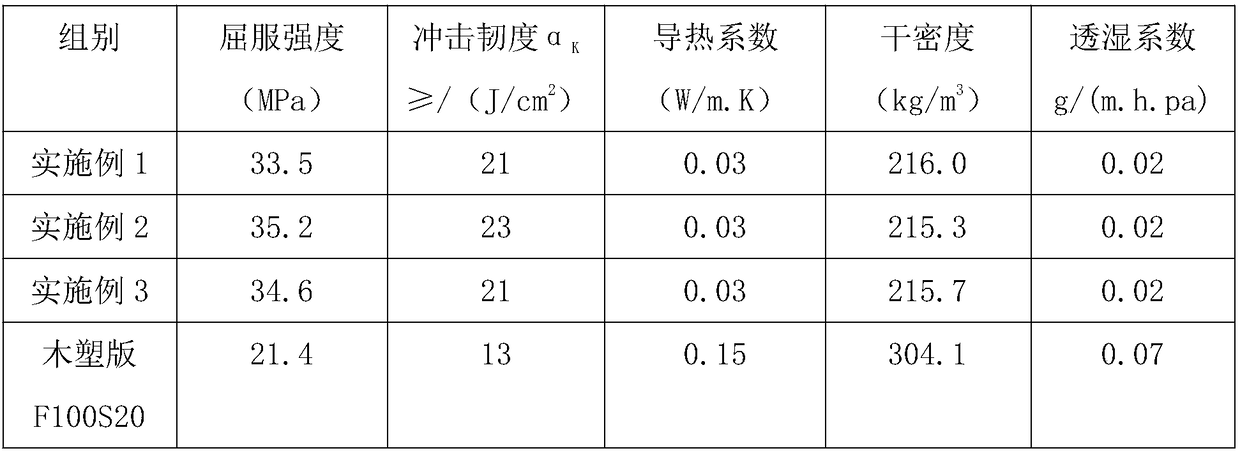

Examples

Embodiment 1

[0026] A lightweight wood-plastic foam board, weighing the following raw materials: 60kg of PVC resin, 20g of terpene resin, 10kg of methyl acrylate, 25kg of modified ramie fiber, 6kg of corn straw powder, 4kg of barium feldspar powder, and faujasite powder 3kg, methyl pentachlorostearate 2kg, oxidized polyethylene wax 1kg, azobisisoheptanonitrile 1kg, N-methylolacrylamide 1kg, calcium zinc stabilizer 1kg, triethoxybutane 1kg, silicone resin Polyether emulsion 1kg, silane coupling agent KH1721kg and trihydroxymethyl phosphorus oxide 1kg;

[0027] Preparation of modified ramie fiber:

[0028] Step 1: Take 25 kg of raw ramie fibers, cut them to a length of less than or equal to 3 mm by a chopping device to obtain chopped ramie fibers; put the chopped ramie fibers into hydrogen peroxide with a volume concentration of 8% for 50 minutes, take them out, and wash them until medium Drying in an oven with a working temperature of 80°C for 35 minutes;

[0029] Step 2: put the chopped ...

Embodiment 2

[0036] A lightweight wood-plastic foam board, weighing the following raw materials: PVC resin 70kg, terpene resin 25kg, methyl acrylate 15kg, modified ramie fiber 30kg, corn straw powder 8kg, feldspar powder 6kg, faujasite powder 4kg, methyl pentachlorostearate 3kg, oxidized polyethylene wax 2kg, azobisisoheptanonitrile 1.5kg, N-methylolacrylamide 1.25kg, calcium zinc stabilizer 1.5kg, sodium azobisisobutyronitrile 3kg, polyacrylamide 1.5kg, silane coupling agent KH5503kg and diphenyl phosphate 2kg;

[0037] Preparation of modified ramie fiber:

[0038] Step 1: Take 30kg of raw ramie fibers, cut them to a length less than or equal to 2mm by a chopping device to obtain chopped ramie fibers; put the chopped ramie fibers into hydrogen peroxide with a volume concentration of 10% for 55 minutes, take them out, and wash them until medium Drying treatment in an oven with a working temperature of 85°C for 40 minutes;

[0039] Step 2: put the chopped ramie fiber treated in step 1 int...

Embodiment 3

[0046] A lightweight wood-plastic foam board, weighing the following raw materials: PVC resin 80kg, terpene resin 30kg, methyl acrylate 20kg, modified ramie fiber 35kg, corn straw powder 10kg, feldspar powder 8kg, faujasite powder 5kg, methyl pentachlorostearate 4kg, oxidized polyethylene wax 3kg, azobisisoheptanonitrile 2kg, N-methylolacrylamide 1.5kg, calcium zinc stabilizer 2kg, azodicarbonamide 5kg, polyethylene Alcohol foam stabilizer 2kg, silane coupling agent KH1715kg and dipentaerythritol 3kg;

[0047] Preparation of modified ramie fiber:

[0048] Step 1: Take 35 kg of raw ramie fibers, cut them to a length of less than or equal to 3 mm by a chopping device to obtain chopped ramie fibers; put the chopped ramie fibers into hydrogen peroxide with a volume concentration of 12% and soak them for 60 minutes, take them out, and wash to medium Drying in an oven with a working temperature of 90°C for 45 minutes;

[0049] Step 2: put the chopped ramie fiber treated in step 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com