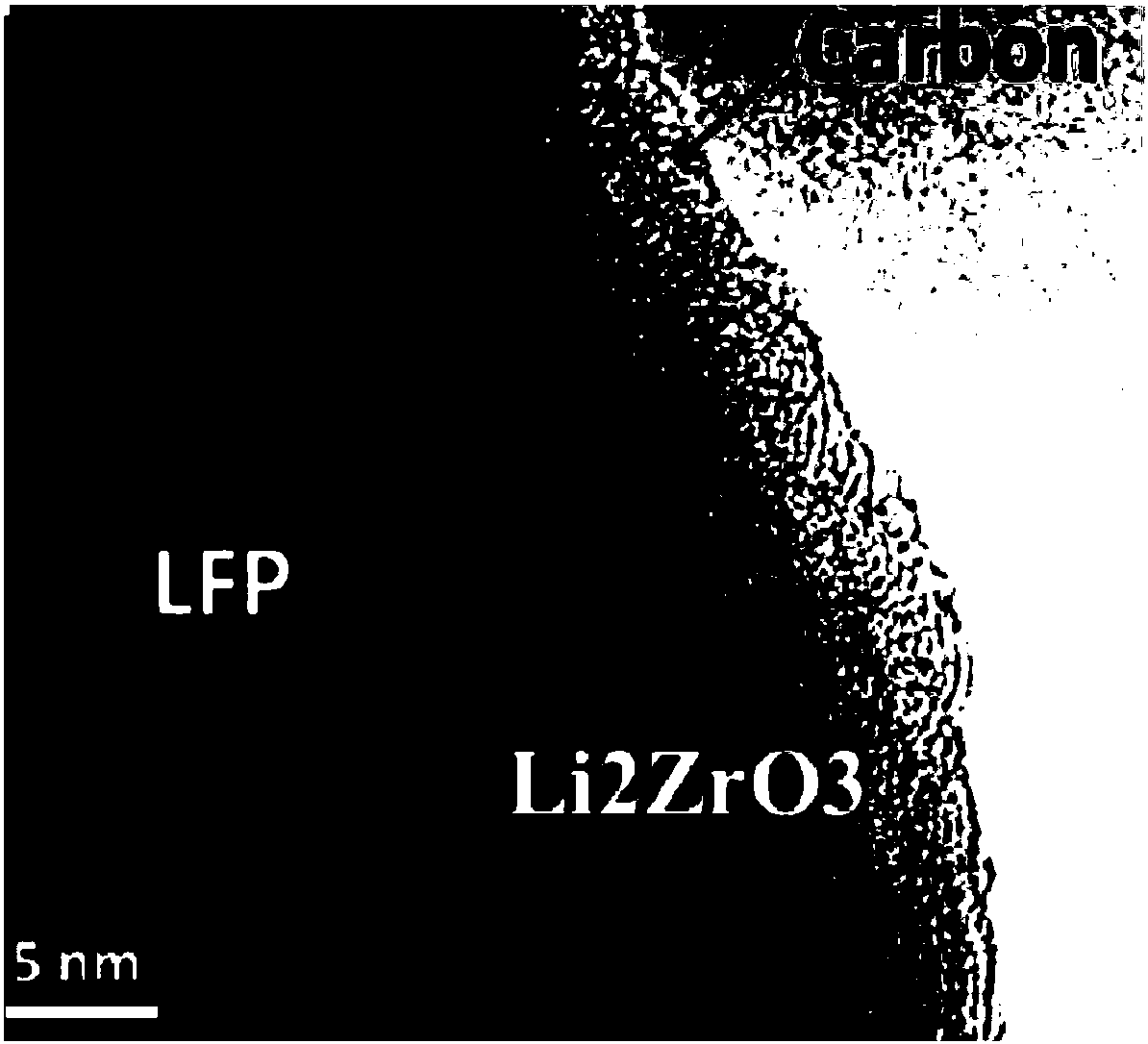

Nanometer lithium zirconate-modified lithium iron phosphate composite material and preparation method thereof

A technology of lithium iron phosphate and composite materials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unsuitable for high-current charging and discharging, practical application limitations, etc., and achieve low-temperature rate performance Excellent, excellent cycle performance, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare the lithium iron phosphate composite material modified by nano lithium zirconate, comprising the following steps: (1) be dissolved in deionized water to form a solution A (2) under the protection of a nitrogen atmosphere, lithium hydroxide, ferrous sulfate, and phosphoric acid are mixed in the solution A according to the molar ratio Li:Fe:P=1:1:1, and vitamin C is added to adjust the pH=8 , stirred for 2 hours to form a mixed solution B; (3) Add the mixed solution B to a hydrothermal kettle, pre-react at 130°C for 2.5 hours, and then cool to room temperature to obtain an intermediate product C; (4) Under the protection of a nitrogen atmosphere , in the intermediate product C, add the aqueous solution D containing cocamidopropyl betaine and polyvinylpyrrolidone, wherein the amount of cocamidopropyl betaine added is 0.8wt% of the quality of lithium iron phosphate; The amount of polyvinylpyrrolidone is 0.8wt% of the quality of lithium iron phosphate, then add lithi...

Embodiment 2

[0030]Prepare the lithium iron phosphate composite material modified by nano lithium zirconate, comprising the following steps: (1) be dissolved in deionized water to form a solution A (2) under the protection of nitrogen atmosphere, according to the molar ratio Li:Fe:P=0.9:1:1 ratio lithium hydroxide, ferrous sulfate, phosphoric acid are mixed in solution A, add vitamin C, adjust pH=7 , stirred for 1.5h to form a mixed solution B; (3) Add the mixed solution B to a hydrothermal kettle, pre-react at 125°C for 2 hours, and then cool to room temperature to obtain an intermediate product C; (4) protect the mixture under a nitrogen atmosphere Next, in the intermediate product C, add the aqueous solution D containing cocamidopropyl betaine and polyvinylpyrrolidone, wherein the amount of cocamidopropyl betaine added is 1.3wt% of the quality of lithium iron phosphate; The amount of polyvinylpyrrolidone is 0.9wt% of the quality of lithium iron phosphate, then add lithium hydroxide and ...

Embodiment 3

[0032] Prepare the lithium iron phosphate composite material modified by nano-lithium zirconate, comprising the following steps: (1) be dissolved in deionized water to form a solution A (2) Under the protection of a nitrogen atmosphere, lithium hydroxide, ferrous sulfate, and phosphoric acid are mixed into solution A according to the molar ratio Li:Fe:P=1.1:1:1, and vitamin C is added to adjust the pH=7 , stirred for 2.5h to form a mixed solution B; (3) Add the mixed solution B to a hydrothermal kettle, pre-react at 135°C for 2.5 hours, and then cool to room temperature to obtain an intermediate product C; (4) protect the intermediate product under a nitrogen atmosphere Next, in the intermediate product C, add the aqueous solution D containing cocamidopropyl betaine and polyvinylpyrrolidone, wherein the amount of cocamidopropyl betaine added is 0.9wt% of the quality of lithium iron phosphate; The amount of polyvinylpyrrolidone is 0.6wt% of the quality of lithium iron phosphate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com