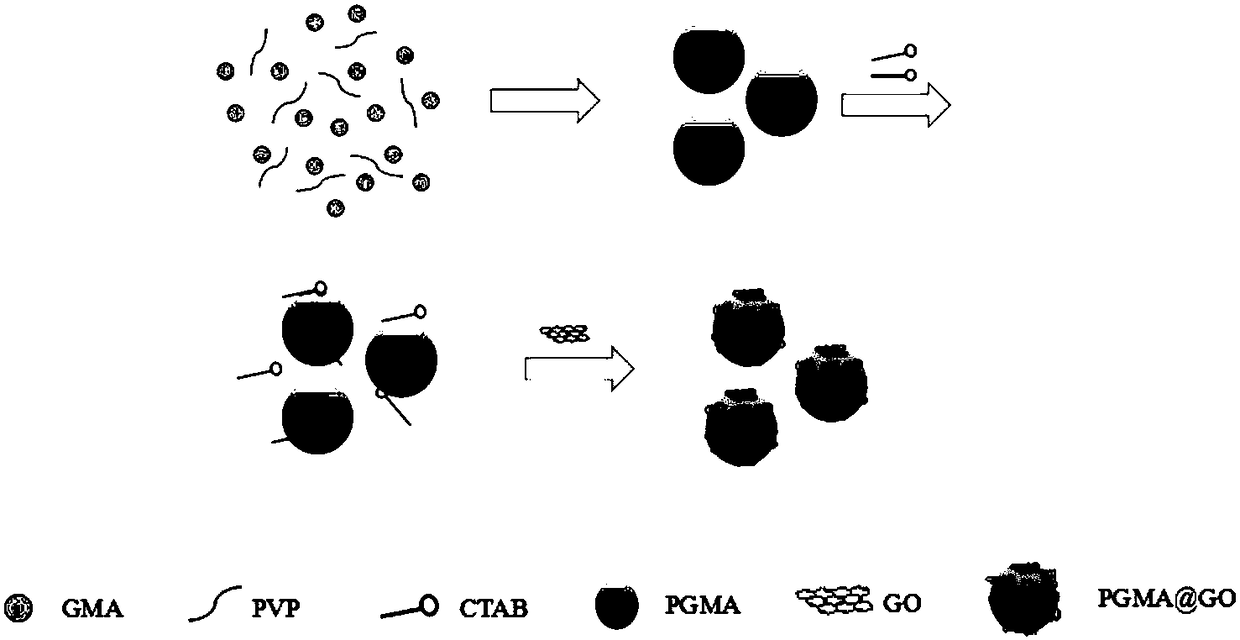

Graphene oxide (GO)-coated PGMA (poly-glycidyl mathacrylate) microsphere composite anti-corrosive coating additive and preparation method thereof

A technology of polymethacrylic acid and glycidyl ester, applied in the direction of coating, etc., can solve problems such as graphene dispersion, achieve the effect of improving dispersion, improving compatibility, and improving agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) In a 250mL three-necked flask, add 1g of polyvinylpyrrolidone (PVP), 120mL of reaction solvent anhydrous ethanol, and a magnetic stirrer in sequence. After PVP is completely dissolved, add 10g of reaction monomer glycidyl methacrylate Esters (GMA), inert gas N 2 After half an hour, the temperature of the reaction system was raised to 70°C;

[0028] (2) After the temperature in (1) is stabilized, use a 5mL syringe to inject 0.25g of initiator azobisisobutyronitrile (AIBN) previously dissolved in absolute ethanol into the reaction system at one time, and react for 24 hours;

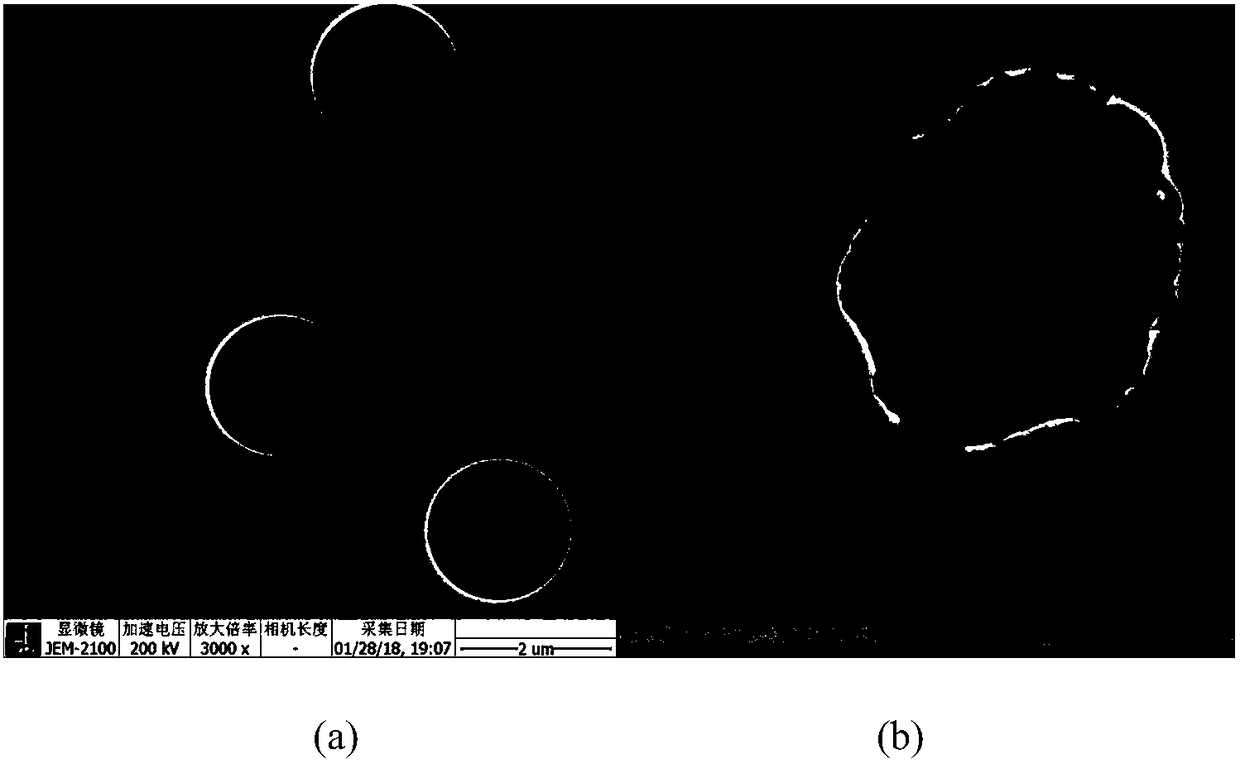

[0029] (3) Centrifuge the reaction solution of (2) at 2600r / min for 5min in a centrifuge, pour off the supernatant after centrifugation, add absolute ethanol and ultrasonically oscillate to disperse for 5min, and wait until the product centrifuged to the bottom of the bottle is redispersed, and then Centrifuge at the same speed and time, repeat the aforementioned operations, wash the product rep...

Embodiment 2

[0038] (1) In a 150mL three-necked flask, add 2g of polyvinylpyrrolidone (PVP), 50mL of reaction solvent anhydrous ethanol, and a magnetic stirrer in sequence. After PVP is completely dissolved, add 10g of reaction monomer glycidyl methacrylate Esters (GMA), inert gas N 2 After half an hour, the temperature of the reaction system was raised to 65°C;

[0039] (2) After the temperature in (1) is stabilized, inject 0.3 g of initiator azobisisobutyronitrile (AIBN) previously dissolved in absolute ethanol into the reaction system at one time with a 5 mL syringe, and react for 24 hours;

[0040] (3) Centrifuge the reaction solution of (2) at 2500r / min for 5min in a centrifuge, pour off the supernatant after centrifugation, add absolute ethanol and ultrasonically oscillate to disperse for 5min, and wait until the product centrifuged to the bottom of the bottle is redispersed, and then Centrifuge at the same speed and time, repeat the aforementioned operations, wash the product repea...

Embodiment 3

[0046] (1) Add weighed 0.45g of polyvinylpyrrolidone (PVP), 30mL of reaction solvent absolute ethanol, and a magnetic stirrer into a 100mL three-necked flask in sequence. After PVP is completely dissolved, add 3g of reaction monomer methacrylic acid to shrink Glyceride (GMA), inert gas N 2 After half an hour, the temperature of the reaction system was raised to 75°C;

[0047] (2) After the temperature in (1) is stabilized, inject 0.126 g of initiator azobisisobutyronitrile (AIBN) previously dissolved in absolute ethanol into the reaction system at one time with a 5 mL syringe, and react for 12 hours;

[0048] (3) Centrifuge the reaction solution of (2) at 2800r / min for 5min in a centrifuge, pour off the supernatant after centrifugation, add absolute ethanol and ultrasonically oscillate to disperse for 5min, and wait until the product centrifuged to the bottom of the bottle is redispersed, and then Centrifuge at the same speed and time, repeat the aforementioned operations, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com