Molybdenum disulfide nanosheet preparation method and application

A technology of molybdenum disulfide and nanosheets, which is applied in the direction of molybdenum sulfide, chemical instruments and methods, and other chemical processes, can solve the problems of high cost and harsh reaction conditions, and achieve the effects of low cost, high reactivity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 0.5000g sodium molybdate (Na 2 MoO 4 2H 2 O), 1.4000g ethyl sodium xanthate sodium (C 3 h 5 OS 2 Na) and 0.4700g citric acid (C 6 h 8 o 7 ) were dissolved in 20mL of deionized water, and magnetically stirred for 15min. After complete dissolution, the pH of the citric acid solution was adjusted to 7.00 with concentrated ammonia water. Then mix all three together. The mixture was transferred to a 100mL autoclave, sealed, placed in an oven at 200°C for 10h, and cooled to room temperature naturally. After centrifugation, the reaction product is washed with deionized water and absolute ethanol several times, collected and vacuum freeze-dried to obtain a black powder product, which is a single-layer and / or few-layer molybdenum disulfide nanomaterial. Among them, sodium molybdate is almost quantitatively converted to molybdenum disulfide.

[0054] Figure 6 The atomic force microscope (AFM) picture of the molybdenum disulfide product prepared for this embodiment sh...

Embodiment 2

[0056] 0.5000g ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 1.2000g sodium isobutyl xanthate (C 5 h 9 OS 2 Na) were dissolved in 30 mL of deionized water, and magnetically stirred for 15 min. After being completely dissolved, the (NH 4 ) 6 Mo 7 o 24 4H 2 The pH of the O solution was adjusted to 7.00, after which the C 5 h 9 OS 2 Na solution was added to it and mixed evenly. The mixture was transferred to a 100mL autoclave, sealed, placed in an oven at 200°C for 8 hours, and cooled to room temperature naturally. After the reaction product is separated by centrifugation, it is washed with deionized water and absolute ethanol several times, collected and vacuum freeze-dried to obtain a black powder product, which is the nano molybdenum disulfide material. Among them, ammonium molybdate is almost quantitatively converted to molybdenum disulfide.

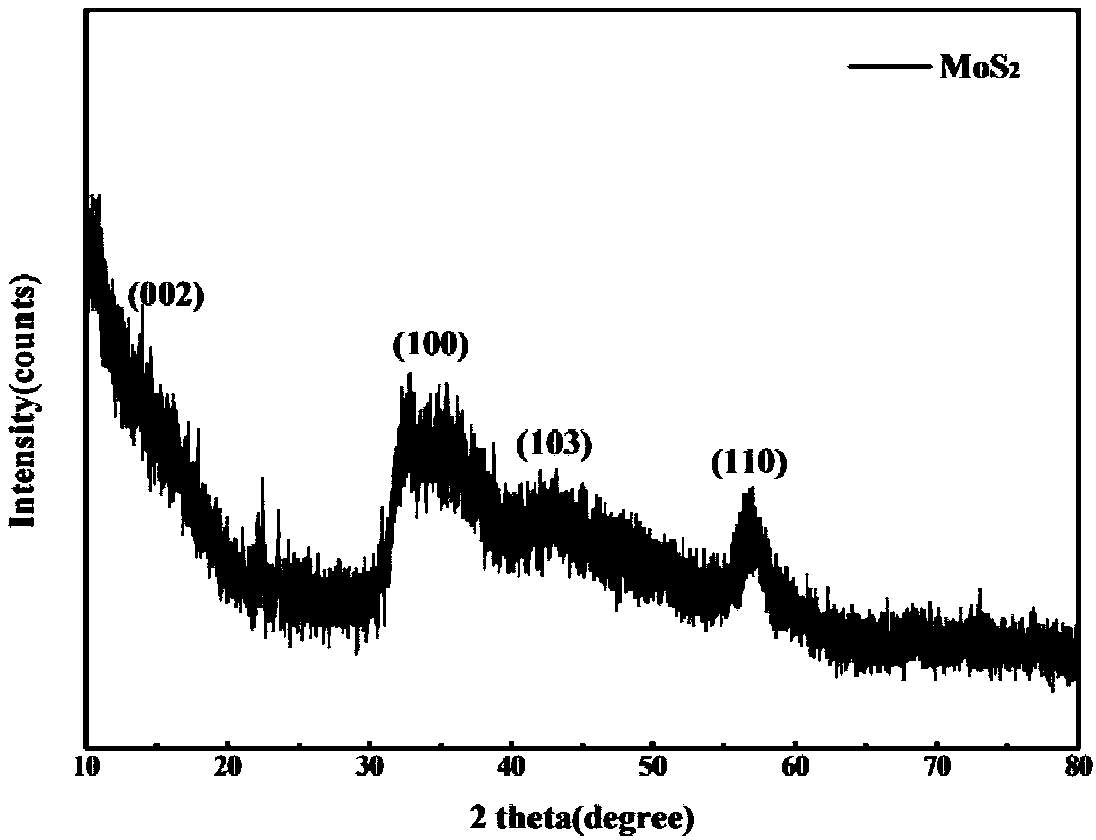

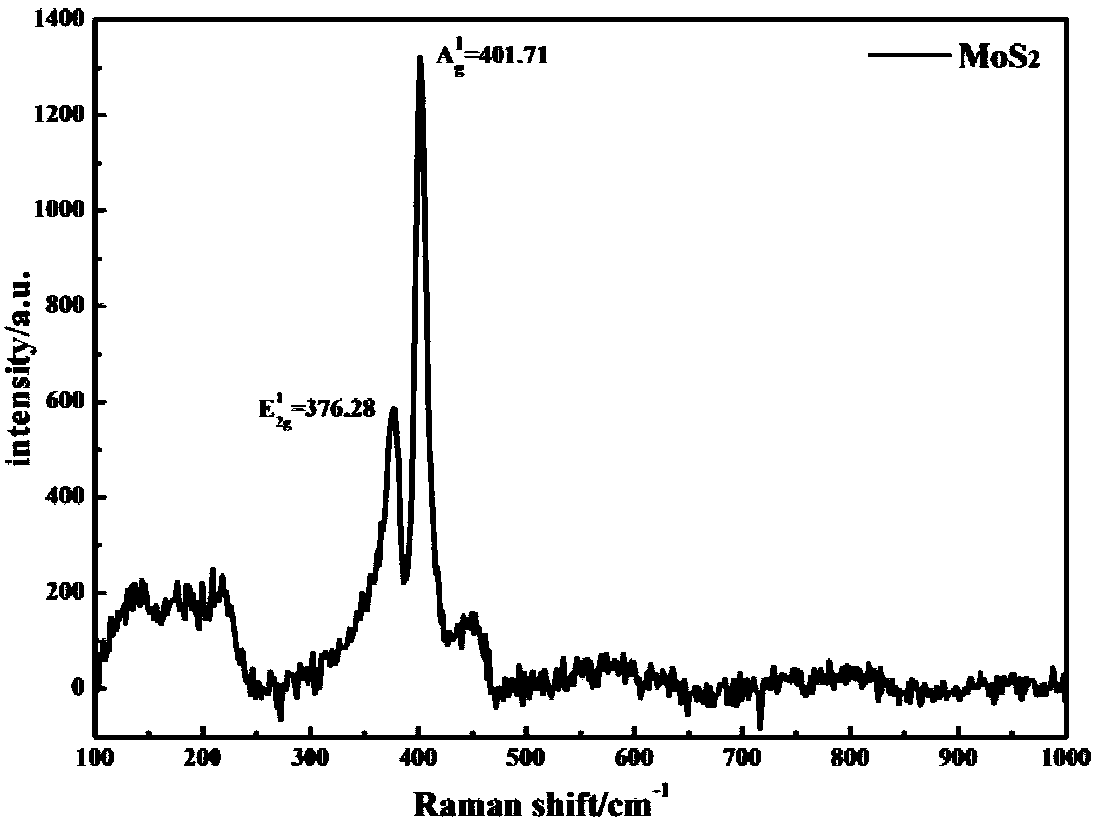

[0057] figure 1 The XRD spectrum of the nano molybdenum disulfide prepared for this example, its diffraction p...

Embodiment 3

[0059] 0.5000gNa 2 MoO 4 2H 2 O, 1.8000g sodium isobutyl xanthate (C 5 h 9 OS 2 Na) and 0.4700g citric acid (C 6 h 8 o 7 ) were dissolved in 20mL of deionized water, and magnetically stirred for 15min. After being completely dissolved, the C 6 h 8 o 7 The pH of the solution was adjusted to 9.00. Then mix all three together. The mixture was transferred to a 100mL autoclave, sealed, placed in an oven at 200°C for 12h, and cooled naturally to room temperature. After the reaction product is separated by centrifugation, it is washed with deionized water and absolute ethanol several times, collected and vacuum freeze-dried to obtain a black powder product, which is the nano molybdenum disulfide material. Among them, sodium molybdate is almost quantitatively converted to molybdenum disulfide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com