Solar cell front surface electrode paste

A solar cell and front electrode technology, applied in the photovoltaic field, can solve the problems of narrow process port, low photoelectric conversion efficiency, large series resistance, etc., and achieve the effect of improving the narrow process port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

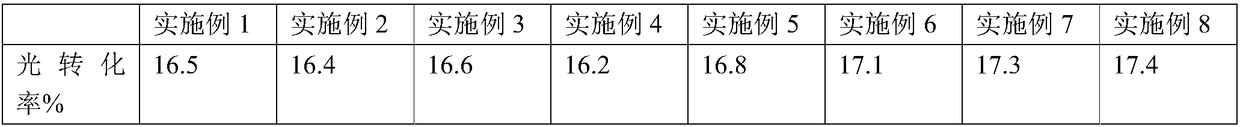

Examples

Embodiment 1

[0041] A solar cell positive electrode paste, comprising the following components: 83.8g of silver powder, 5g of glass powder, 8g of organic vehicle, and 2g of functional additives.

[0042] The glass powder includes the following components: 20 parts of lead oxide, 15 parts of bismuth oxide, 8 parts of silicon oxide, 5 parts of boron oxide, 1 part of aluminum oxide, 3 parts of zinc oxide, 30 parts of antimony oxide, 4 parts of sodium carbonate parts, 2 parts of lithium oxide, 5 parts of alum oxide, and 0.1 part of sodium fluoride.

Embodiment 2

[0044] A solar cell positive electrode paste, comprising the following components, silver powder 95g, glass powder 1g, organic vehicle 15g, functional additive 0.2g. The glass powder includes the following components: 35 parts of lead oxide, 8 parts of bismuth oxide, 18 parts of silicon oxide, 2 parts of boron oxide, 3 parts of aluminum oxide, 1 part of zinc oxide, 40 parts of antimony oxide, 2 parts of sodium carbonate 15 parts of lithium oxide, 1 part of alum oxide, and 3 parts of sodium fluoride.

Embodiment 3

[0046] A solar cell positive electrode paste, comprising the following components: 91 parts of silver powder, 1 part of glass powder, 10 parts of organic vehicle, and 0.2 part of functional additives. The glass powder includes the following components: 20 parts of lead oxide, 15 parts of bismuth oxide, 8 parts of silicon oxide, 5 parts of boron oxide, 1 part of aluminum oxide, 3 parts of zinc oxide, 30 parts of antimony oxide, 4 parts of sodium carbonate parts, 2 parts of lithium oxide, 5 parts of alum oxide, and 0.1 part of sodium fluoride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com