Organosilicon modified high-temperature-resistant acrylate pressure-sensitive adhesive and preparation method thereof

An acrylate and silicone technology, used in adhesives, ester copolymer adhesives, graft polymer adhesives, etc., can solve the problem of lack of temperature resistance, and achieve strong adhesion and adhesion. , use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

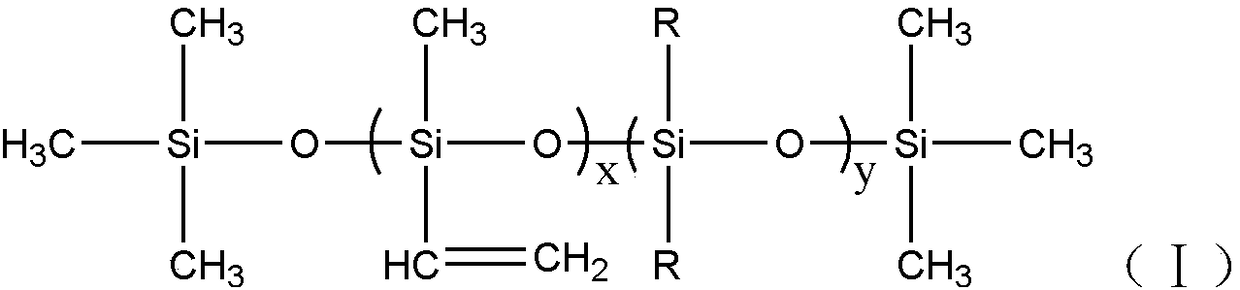

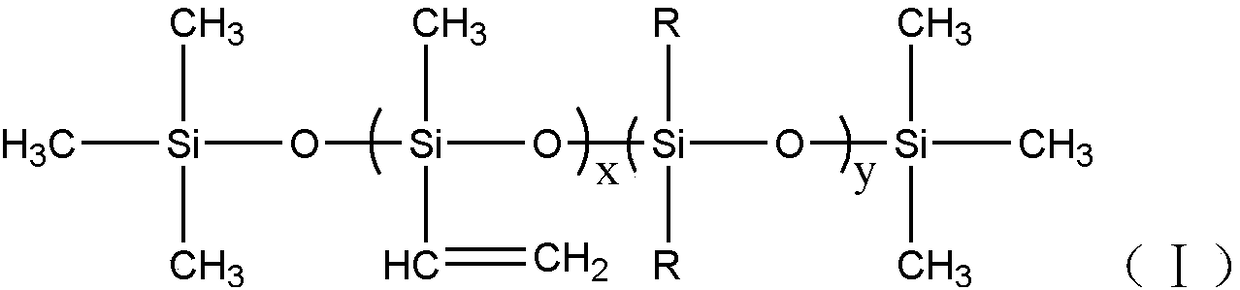

[0037] The preparation scheme of organosilicon modified body is as follows:

[0038] 1) Octaphenylcyclotetrasiloxane 37 parts, D4 57 parts, V4 5.7 parts, MM 0.3 parts, CF 3 SO 3 0.15 parts of H were mixed and added to a three-neck flask equipped with a stirring magnet, a thermometer and a condenser.

[0039] 2) Start nitrogen protection, set the temperature at 75°C, and react for 5 hours.

[0040] 3) Finally, the temperature is lowered to stop the reaction.

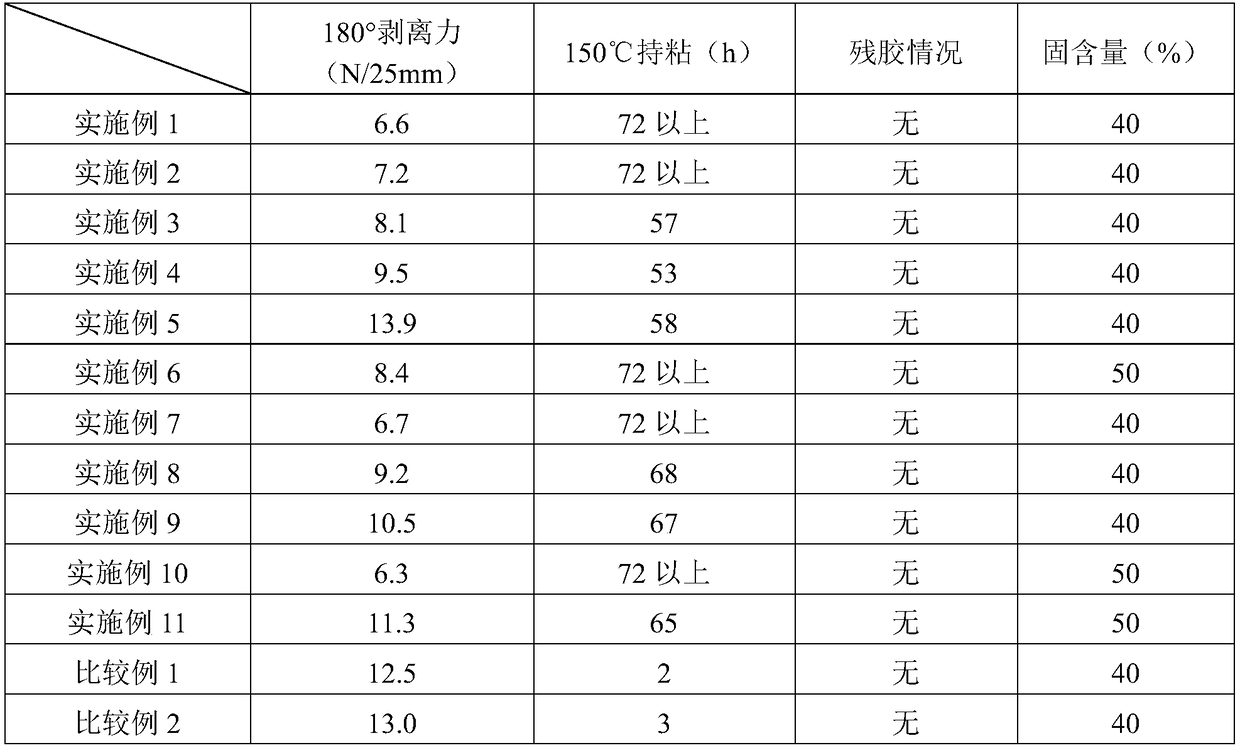

[0041] Performance Testing:

[0042] Pressure-sensitive adhesive tape 180 ° peel strength test method GB / T2792-1998

[0043] Pressure-sensitive adhesive tape stickiness test method GB / T4851—1998 (where the temperature is set to the highest temperature for self-exploration)

[0044] Pressure-sensitive adhesive heat resistance test method: the sample preparation method is the same as the pressure-sensitive adhesive tape 180° peel strength test method GB / T2792-1998, and then put it in an oven at 150°C, take it out after...

Embodiment 1

[0048] 1) After mixing butyl acrylate 51g, isooctyl acrylate 30g, vinyl acetate 5g, acrylic acid 2g, and hydroxyethyl acrylate 2g, get 60% of it and add 75g of solvent (ethyl acetate:toluene:cyclohexane = 3:1:4), and 0.12g of initiator AIBN was heated to 80°C for reflux reaction, and when the viscosity of the reaction started to increase, start timing for 1h.

[0049] 2) After 1 hour, the remaining monomer, 50 g of solvent and 0.03 g of AIBN were uniformly added dropwise into the reaction system within 2 hours using a constant liquid funnel, and then kept for 0.5 hours of reaction.

[0050] 3) Add 0.15g of initiator, 25g of solvent and 10g of modified silicone into the reaction system dropwise within 1h, and then keep warm for 1.5h.

[0051] 4) Finally cooling and discharging, the solid content is 40%.

[0052] Take a part of the prepared glue and weigh it and add 1.5% L75 of the glue amount and stir it fully, then apply it on the PET release paper with a glass rod with a dia...

Embodiment 2

[0054] 1) After mixing 51g of butyl acrylate, 32.5g of isooctyl acrylate, 5g of vinyl acetate, 2g of acrylic acid, and 2g of hydroxyethyl acrylate, get 60% of it and add 75g of solvent (ethyl acetate: toluene: cyclohexane =3:1:4), and 0.12g of initiator AIBN was heated to 80°C for reflux reaction, and when the reaction viscosity increased, start timing for 1h.

[0055] 2) After 1 hour, the remaining monomer, 50 g of solvent and 0.03 g of AIBN were uniformly added dropwise into the reaction system within 2 hours using a constant liquid funnel, and then kept for 0.5 hours of reaction.

[0056] 3) Add 0.15g of initiator, 25g of solvent and 7.5g of modified organic silicon into the reaction system dropwise within 1h, and keep warm for 1.5h.

[0057] 4) Finally cooling and discharging, the solid content is 40%.

[0058] Take a part of the prepared glue and weigh it and add 1.5% L75 of the glue amount and stir it fully, then apply it on the PET release paper with a glass rod with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com