Gas compressor circle-arc tooth rotor blade vibration fatigue test fixture

A rotor blade and vibration fatigue technology, which is applied in the field of fatigue performance test fixtures, can solve problems such as high replacement rate of vibration fatigue fixtures, inability to transfer vibration system energy, and difficulty in finding the cause of test failure, so as to facilitate the adjustment of the excitation point position and improve Energy transfer efficiency, vibration sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

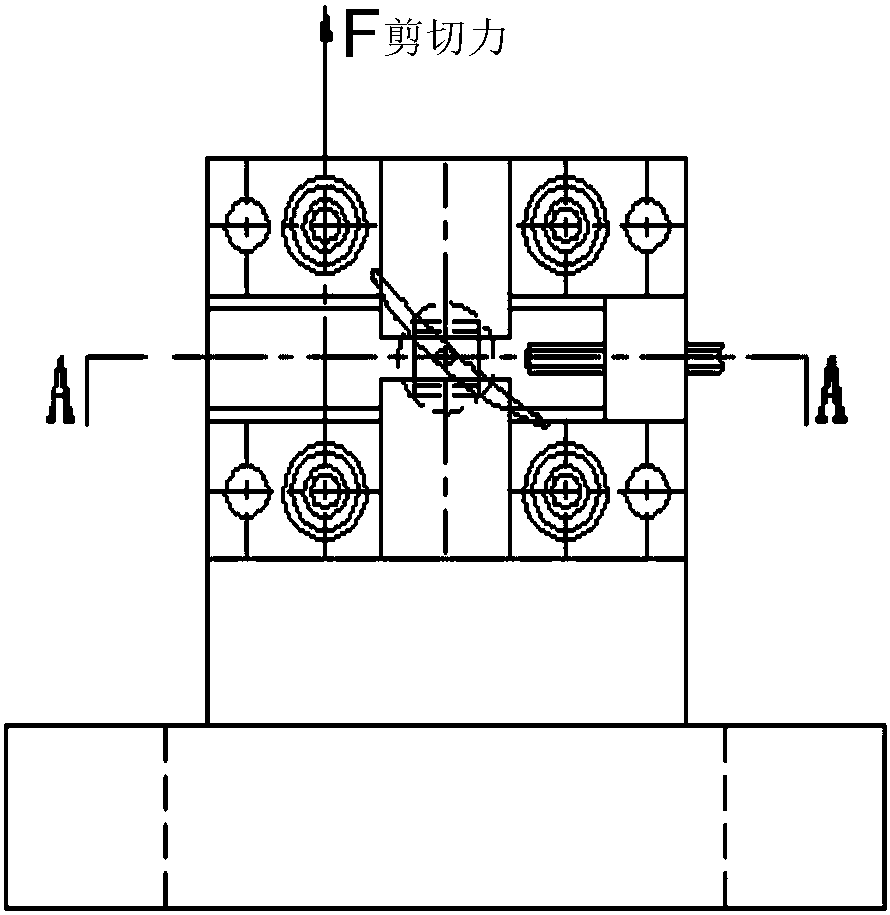

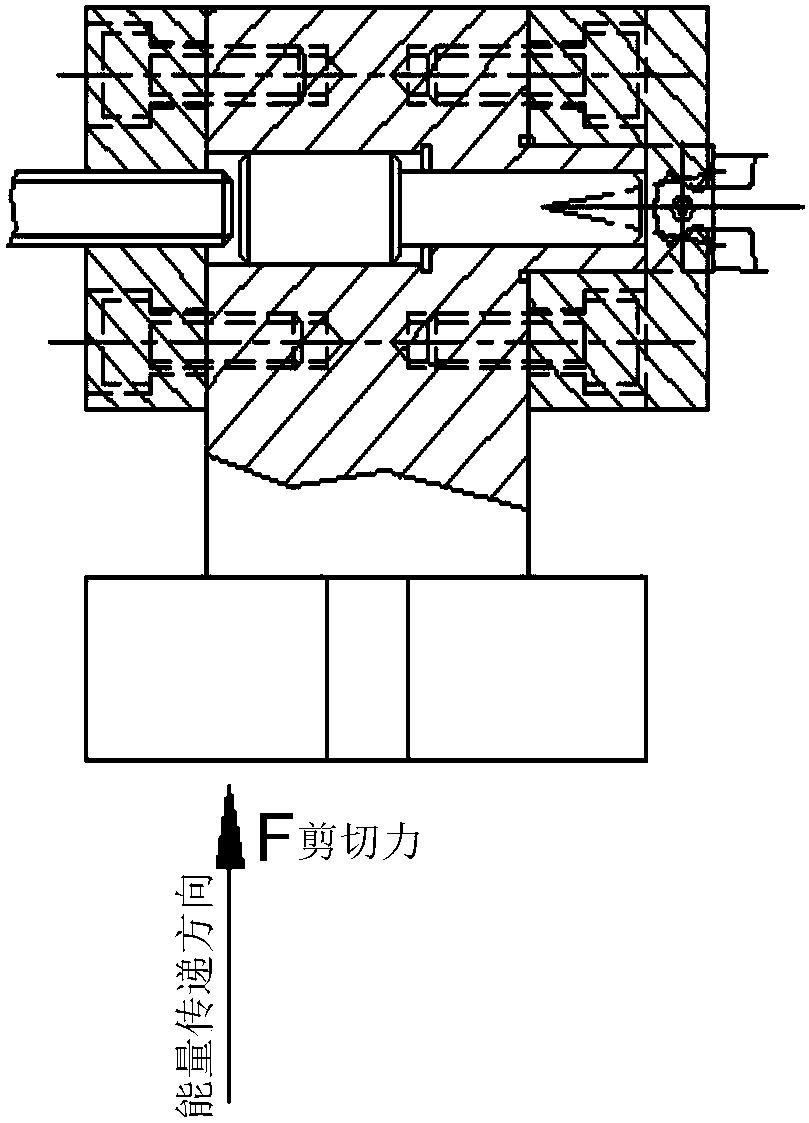

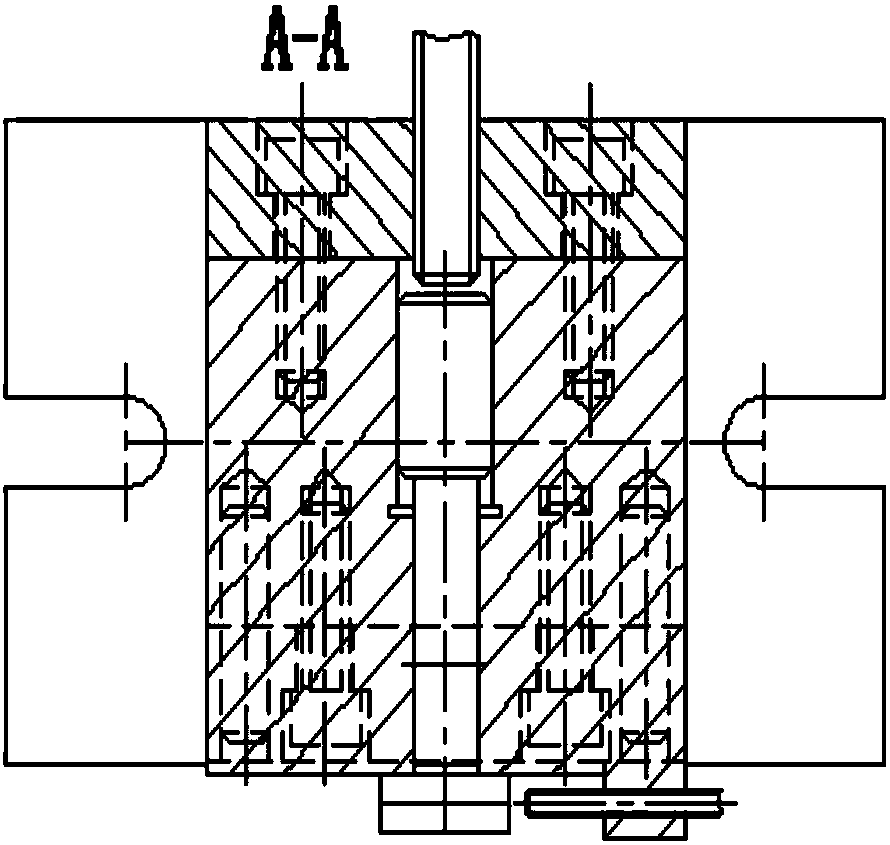

[0032] figure 2 It is the structural diagram of the elevation angle fixture of the present invention, the arc-tooth tenon chuck 2 is fixed on the base 1 with an inclined angle at the upper end, fixed with connecting bolts 5, and two positioning pins 4 are used to ensure the arc-tooth tenon chuck 2 position on base 1 (eg Figure 4 , that is, the arc-tooth tenon chuck 2 is fixed on the arc-tooth tenon chuck mounting surface 3 on the upper side of the base 1), and the blade body is placed in a horizontal position through the angle designed by the base 1 with an elevation angle, so that the blade body The vibration is sensitive, which is convenient for the vibration system to collect effective data. At the same time, the arc-tooth tenon chuck 2 is clamped on the base 1 with an elevation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com