Preparation method of motor iron cores

A technology of iron core and soft magnetic metal, applied in the field of preparation of motor iron core, can solve the problems of slow processing speed, damage, edge drop, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the motor iron core of the present invention is to laminate the soft magnetic metal strips, cut the laminates with a laser after fixing, stack the strip slices to a certain thickness, perform atmosphere annealing, solidify the adhesive, and spray paint. The invention has the advantages of high machining precision for preparing motor iron cores by laser cutting, no burr, small internal stress, and can process motor iron cores with complicated shapes. Using the laser method to prepare the motor core can simplify the production process, increase the processing speed and reduce the cost, and has broad application prospects in the field of high-speed motor manufacturing.

[0030] The present invention adopts concrete steps as follows:

[0031] 1) Soft magnetic metal strip lamination, fixed

[0032] One of the silicon steel strips, iron-based amorphous strips, iron-cobalt-based amorphous strips, and iron-based nanocrystalline strips is transversely ...

Embodiment 1

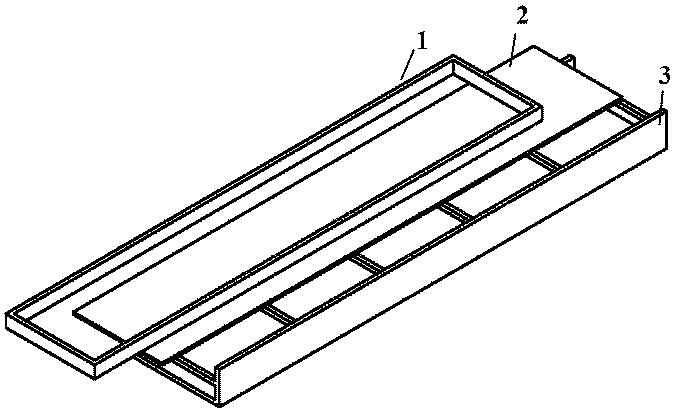

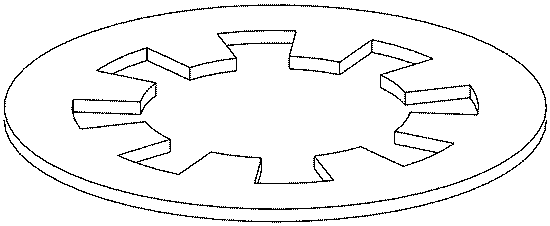

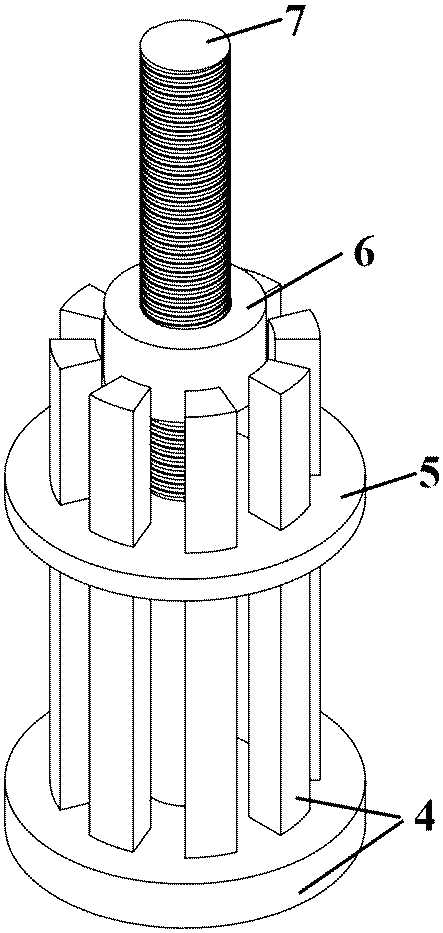

[0041] The FeSiB amorphous strip, with a width of 213mm and a thickness of 30um, is cut into 2m long fragments and laminated in a jig with a thickness of 5mm. figure 1 The lamination clamps shown are clamped to obtain a strip lamination. Place the strip lamination on the laser gun of the fiber laser, focus the laser light, and incident it vertically on the soft magnetic metal strip lamination. At the same time, pass the coaxial air. The laser power is 800W, and the cutting speed is 30m / min. figure 2 A section of soft magnetic metal strip is shown. Take advantage of image 3 In the mold shown, the soft magnetic metal strip slices are stacked to the design height of the iron core, clamped, and annealed in a nitrogen atmosphere. The annealing temperature is 250°C and the annealing time is 1h. Put the annealed iron core into the adhesive solution for 1 hour, so that the adhesive penetrates into the single-layer laminate. The adhesive solution is an alcohol solution of epoxy res...

Embodiment 2

[0044] The FeSiB amorphous strip, with a width of 170mm and a thickness of 30um, is cut into 2m-long pieces and laminated in a jig with a thickness of 3mm. figure 1 The lamination clamps shown are clamped to obtain a strip lamination. Place the strip lamination on the laser gun of the YAG laser, focus the laser, and incident it vertically on the soft magnetic metal strip lamination. At the same time, coaxial oxygen is passed through. The laser power is 500W and the cutting speed is 20m / min. figure 2A section of soft magnetic metal strip is shown. Take advantage of image 3 In the mold shown, the soft magnetic metal strip slices are stacked to the design height of the iron core, clamped, and annealed in an argon atmosphere. The annealing temperature is 300°C and the annealing time is 1.5h. Put the annealed iron core into the adhesive solution for 1.5h, so that the adhesive penetrates into the single-layer lamination. The adhesive solution is an acetone solution of epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com