Method for preparation of flexible self-support electrode with graphene as conductive binder and electrode

A technology of self-supporting electrodes and conductive binders, applied in battery electrodes, hybrid capacitor electrodes, electrolytic capacitors, etc., can solve the problems of damaging the electrochemical performance of active materials, limiting the energy density of energy storage devices, and high cost, and achieving improvement Electronic conductivity and ion mobility, avoiding the use of current collectors, and the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) With 50 mesh expanded graphite as raw material, large-size graphene oxide is prepared by the Hummers method;

[0039] 2) Take 22.4mg of artificial graphite powder (particle size about 15μm), put it into a weighing bottle, add 3mL of 4.915mg / mL graphene oxide solution, stir magnetically for 2 hours and place it in an ultrasonic cleaning device for ultrasonic dispersion for 30 minutes to make it well mixed;

[0040] 3) Pour the product of step 2) into a petri dish with a diameter of 55 mm, and freeze-dry to obtain a round cake-shaped airgel;

[0041] 4) Press the product obtained in step 3) into thin slices with a pressure of 10 MPa with a hydraulic press, and cut it into small discs with a diameter of 12 mm with a slicer;

[0042] 5) The product obtained in step 4) is calcined and reduced in a tube furnace at 600°C for 3 hours in an argon protective atmosphere (the mass ratio of graphene:artificial graphite after reduction is about 1:4), and a graphene-based flexible...

Embodiment 2

[0047] 1) With 50 mesh expanded graphite as raw material, large-size graphene oxide is prepared by the Hummers method;

[0048]2) Take 22.4 mg of commercial lithium iron phosphate powder (particle size about 1 μm), put it into a weighing bottle, add 3 mL of 4.915 mg / mL graphene oxide solution, stir magnetically for 2 hours and place it in an ultrasonic cleaner for ultrasonic dispersion for 30 minutes to mix well;

[0049] 3) Pour the product of step 2) into a petri dish with a diameter of 55 mm, and freeze-dry to obtain a round cake-shaped airgel;

[0050] 4) Compress the product obtained in step 3) into thin slices with a pressure of 20 MPa with a hydraulic press, and cut it into small discs with a diameter of 12 mm with a slicer;

[0051] 5) The product obtained in step 4) is calcined and reduced in a tube furnace at 600°C for 3 hours in an argon protective atmosphere (the mass ratio of graphene: lithium iron phosphate after reduction is about 1:4), and graphene-based flexi...

Embodiment 3

[0053] 1) With 50 mesh expanded graphite as raw material, large-size graphene oxide is prepared by the Hummers method;

[0054] 2) Take 11.2mg of silicon nanoparticles (particle size about 200nm), put them into a weighing bottle, add 3mL of 4.915mg / mL graphene oxide solution, stir magnetically for 2 hours and place in an ultrasonic cleaner for ultrasonic dispersion for 30 minutes to make it well mixed;

[0055] 3) Pour the product of step 2) into a petri dish with a diameter of 55 mm, and freeze-dry to obtain a round cake-shaped airgel;

[0056] 4) Press the product obtained in step 3) into thin slices with a pressure of 40 MPa with a hydraulic press, and cut it into small discs with a diameter of 12 mm with a slicer;

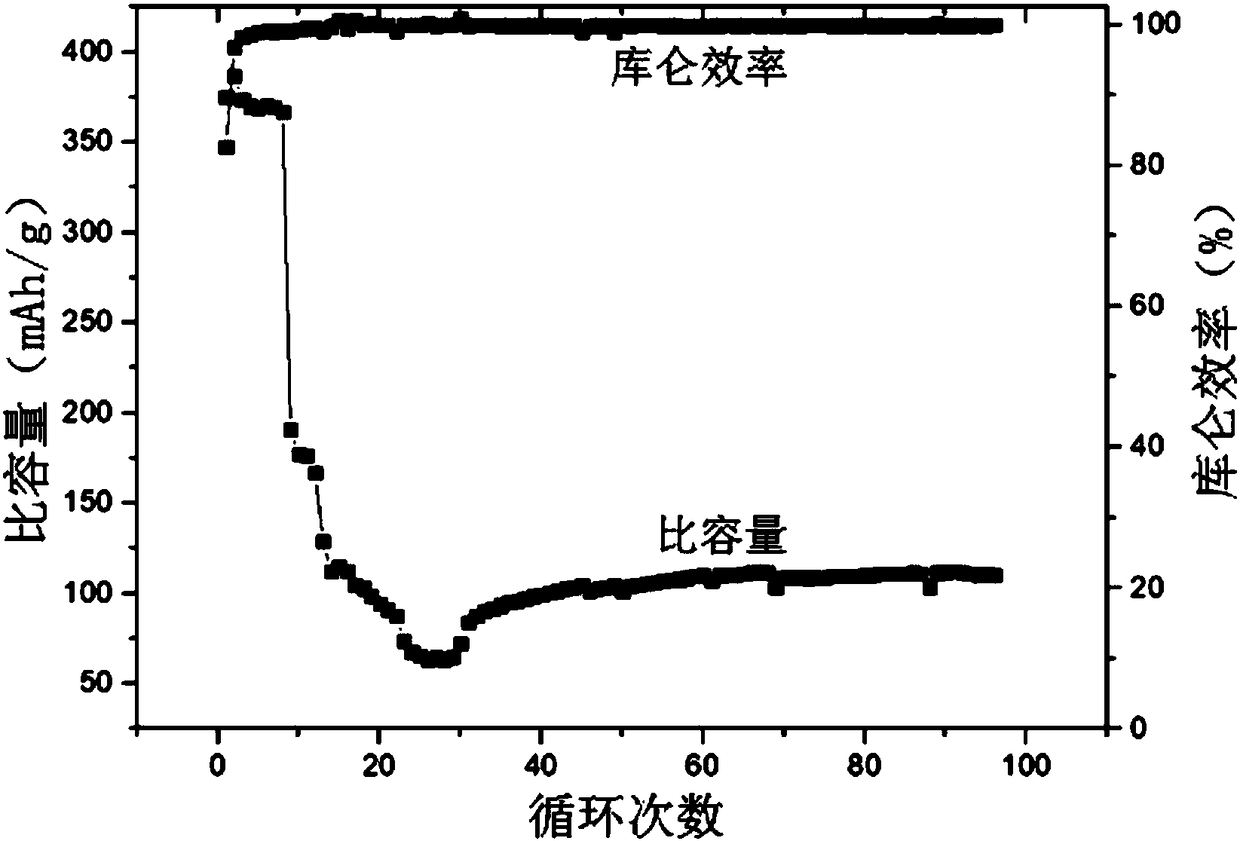

[0057] 5) The product obtained in step 4) is calcined and reduced in a tube furnace at 600° C. for 3 hours in an argon protective atmosphere (the mass ratio of graphene:silicon after reduction is about 1:2), and a graphene-based flexible silicon electrode is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com