Composite film and preparation method thereof

A composite film and film technology, applied in the field of composite film and its preparation, can solve problems such as many surface holes, achieve the effects of convenient operation, improved photocatalytic performance and corrosion resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of composite film, comprises the following steps:

[0033] (1) The substrate is sequentially degreased, sanded and cleaned to obtain a pretreated substrate;

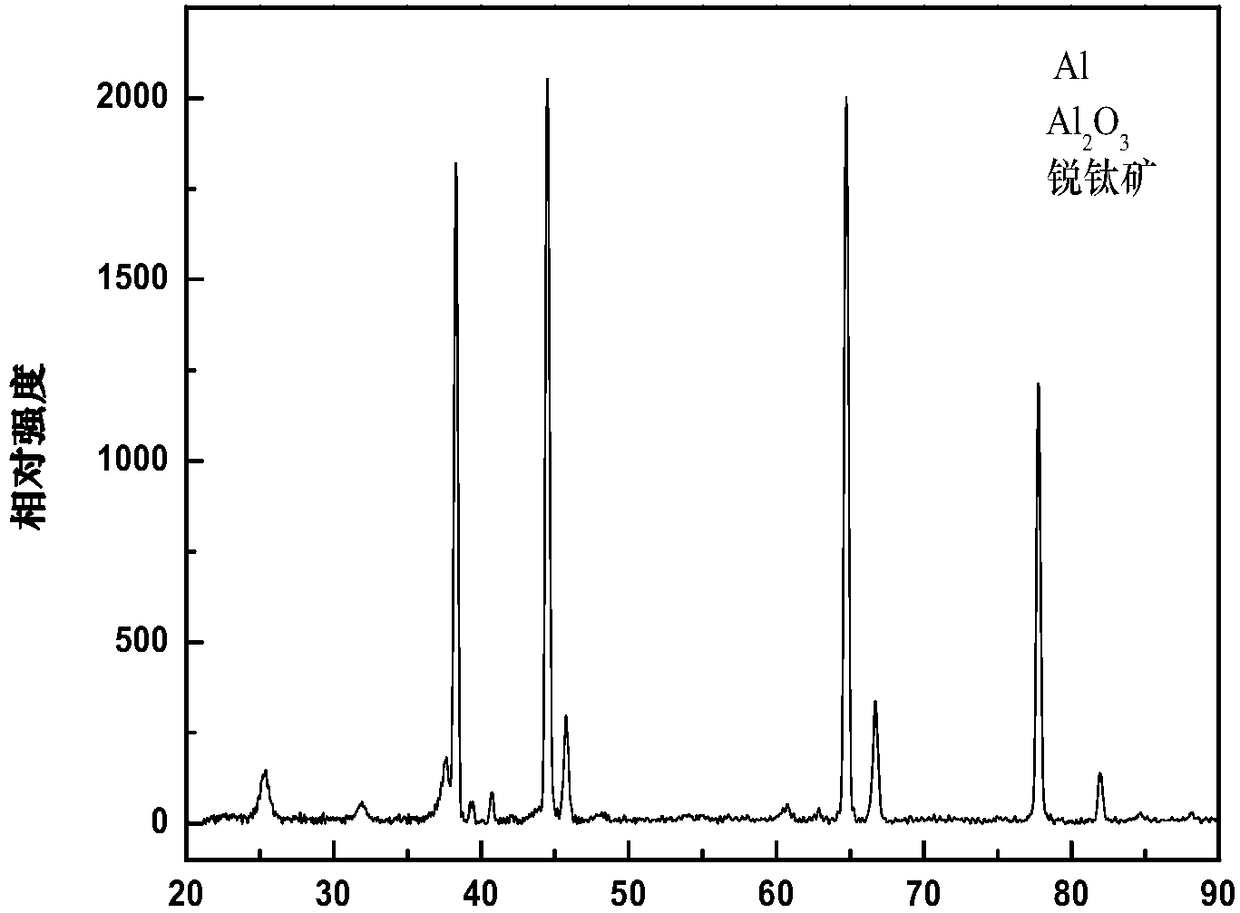

[0034] (2) carrying out the micro-arc oxidation coating film in the electrolytic solution containing nano-titanium dioxide with the pretreatment substrate that described step (1) obtains, obtains the micro-arc oxidation film;

[0035] (3) performing sol-gel coating on the micro-arc oxidation film obtained in the step (2) to obtain a composite film precursor;

[0036] (4) Drying and annealing the composite thin film precursor obtained in the step (3) in sequence to obtain a composite thin film.

[0037] In the invention, the substrate is degreased, sanded and cleaned in sequence to obtain the pretreated substrate. In the present invention, the base body is preferably aluminum alloy, and the size of the base body is preferably 20×10×3 mm. In the present inventio...

Embodiment 1

[0070] (1) Substrate pretreatment: first, the aluminum alloy substrate is made into a small sample with a size of 20×10×3 mm by wire cutting. Then the samples were subjected to degreasing, grinding, cleaning and other processes.

[0071] ① Degreasing: ultrasonically clean the cut substrate with acetone for 20 minutes, and dry it for later use;

[0072] ②Grinding: Use 200#, 400#, 600#, 800#, 1000# sandpaper to polish the surface of the sample step by step;

[0073] ③Cleaning: ultrasonically clean the polished samples with alcohol and deionized water for 20 minutes respectively.

[0074] (2) Preparation of micro-arc oxidation film:

[0075] ① Preparation of electrolyte: Before micro-arc oxidation, first weigh 10g / L sodium silicate, 1g / L potassium hydroxide, and 4g / L nano-titanium dioxide, then add the corresponding volume of deionized water into the electrolytic cell, and stir. Allow the electrolyte to fully dissolve and mix well.

[0076] ②Connecting electrodes: hang the sa...

Embodiment 2

[0094] (1) Substrate pretreatment: first, the aluminum alloy substrate is made into a small sample with a size of 20×10×3 mm by wire cutting. Then the samples were subjected to degreasing, grinding, cleaning and other processes.

[0095] ① Degreasing: ultrasonically clean the cut substrate with acetone for 20 minutes, and dry it for later use;

[0096] ②Grinding: Use 200#, 400#, 600#, 800#, 1000# sandpaper to polish the surface of the sample step by step;

[0097] ③Cleaning: ultrasonically clean the polished samples with alcohol and deionized water for 20 minutes respectively.

[0098] (2) Preparation of micro-arc oxidation film:

[0099] ① Preparation of electrolyte: Before micro-arc oxidation, first weigh 5g / L sodium silicate, 2g / L potassium hydroxide, and 1g / L nano-titanium dioxide, then add the corresponding volume of deionized water into the electrolytic cell, and stir. Allow the electrolyte to fully dissolve and mix well.

[0100] ②Connecting electrodes: hang the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com