Organic silicone thickening agent and preparation method thereof

A technology of organosilicon tackifier and propyltrimethoxysilane, applied in adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problems of inability to remove the chloroplatinic acid catalyst and difficult control of the reaction process, etc. Achieve the effect of good quality, less impurities and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

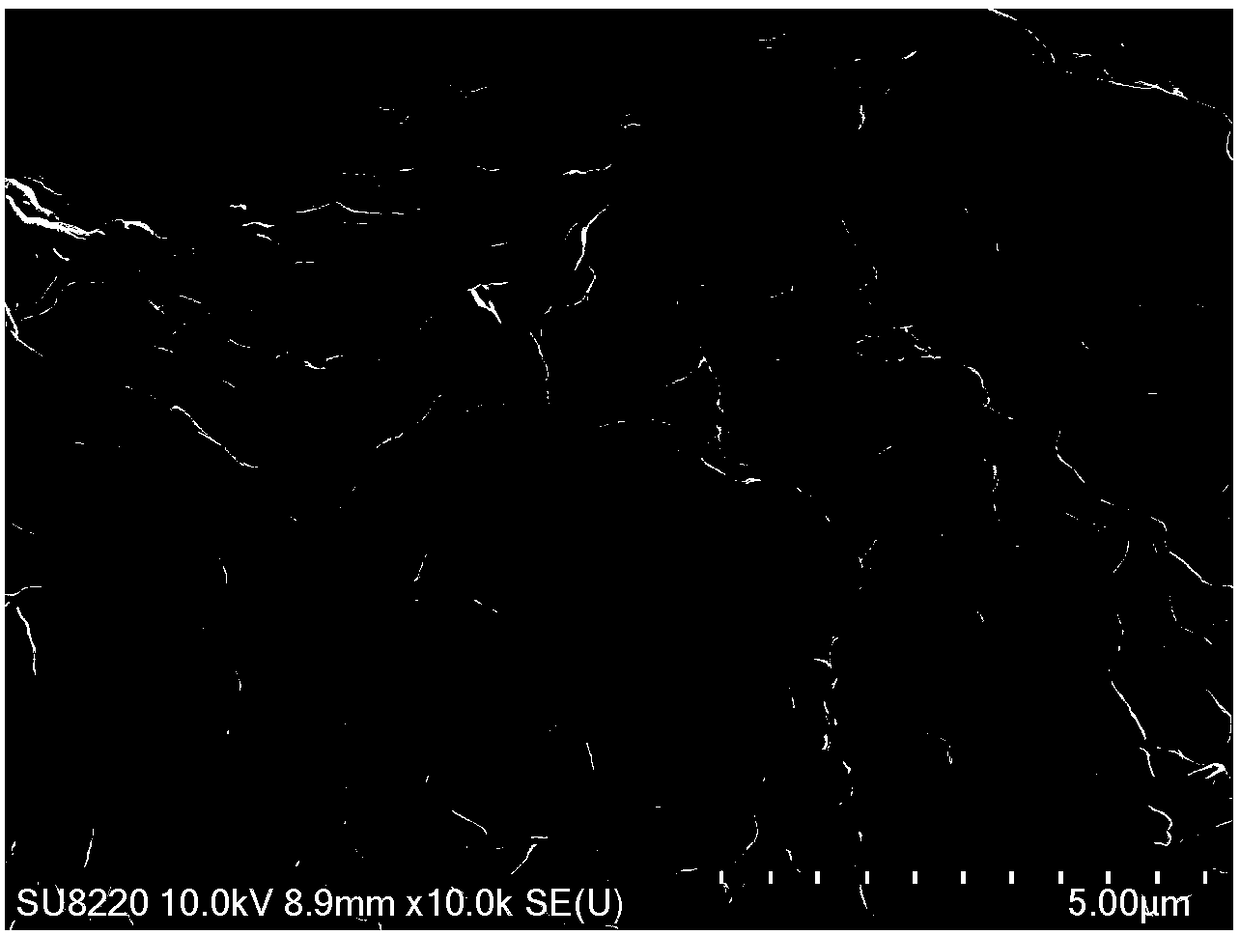

Image

Examples

Embodiment 1

[0024] (1) Take 0.2mol of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 0.1mol of vinyltrimethoxysilane and 0.2mol of hydroxyl-terminated silicone oil into a 250ml three-port with mechanical stirring and temperature controller In the flask, a barium hydroxide monohydrate catalyst accounting for 1% by mass fraction of the total reactants was then added to react at 95° C. for 4 hours.

[0025] (2) After the reaction is finished, the product is suction-filtered under reduced pressure to remove the catalyst, then the filtrate is transferred to a round-bottomed distillation flask, and the low-boiling by-product methanol in the system is removed by vacuum distillation at 100°C / -0.096MPa. Thus a colorless and transparent silicone tackifier is obtained. The detected viscosity is 5.0mpa.s and the refractive index is 1.4133.

Embodiment 2

[0027] (1) Take 0.15mol of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 0.15mol of vinyltrimethoxysilane and 0.2mol of hydroxyl-terminated silicone oil into a 250ml three-port with mechanical stirring and temperature controller In the flask, a barium hydroxide monohydrate catalyst accounting for 1% by mass fraction of the total reactants was then added to react at 95° C. for 4 hours.

[0028] (2) After the reaction is finished, the product is filtered under reduced pressure to remove the catalyst, and then the filtrate is transferred to a round-bottomed distillation flask, and the low-boiling by-product methanol in the system is removed at 100°C / -0.096MPa to obtain Colorless and transparent silicone adhesion promoter. The tested viscosity is 5.5mpa.s and the refractive index is 1.4085.

Embodiment 3

[0030] (1) Take 0.2mol of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 0.1mol of vinyltrimethoxysilane and 0.2mol of hydroxyl-terminated silicone oil into a 250ml three-port with mechanical stirring and temperature controller In the flask, a barium hydroxide monohydrate catalyst accounting for 1% by mass fraction of the total reactants was added and reacted at 100° C. for 4 hours.

[0031] (2) After the reaction is finished, the product is filtered under reduced pressure to remove the catalyst, and then the filtrate is transferred to a round-bottomed distillation flask, and the low-boiling by-product methanol in the system is removed at 100°C / -0.096MPa to obtain Colorless and transparent silicone adhesion promoter. The tested viscosity is 6.0mpa.s and the refractive index is 1.4110.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com