A far-red fluorescent glass ceramic, its preparation method and plant lamp

A technology of fluorescent glass and red fluorescent powder, which is applied in the field of plant lights, to achieve simple and fast control process, good plant lighting effect, and good effect of increasing plant production and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

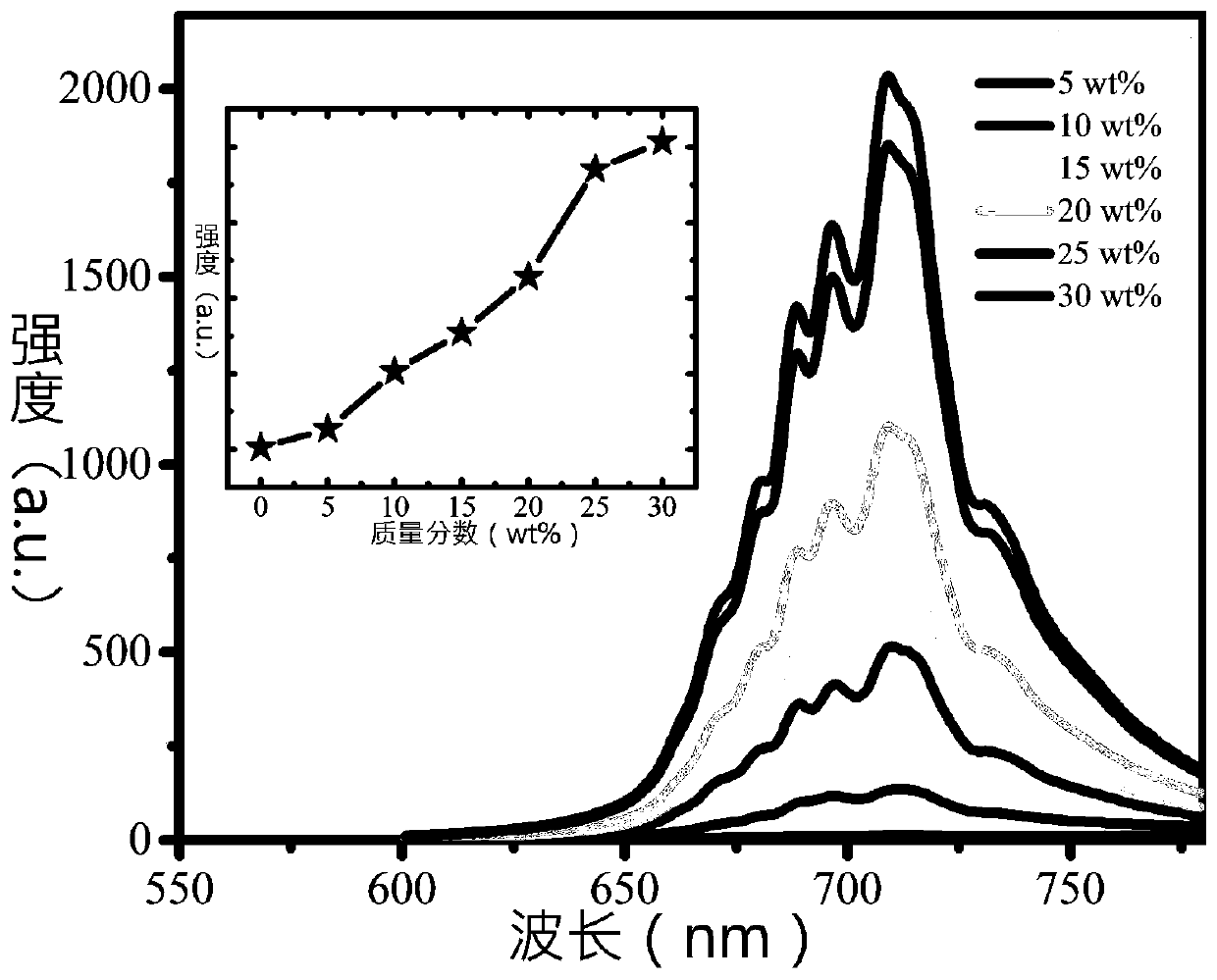

[0048] The red fluorescent powder of the present invention is prepared by the following method: Weigh zinc oxide powder, gallium trioxide powder and chromium trioxide powder according to the structural formula, mix the above-mentioned raw materials after weighing, place the temperature in a high-temperature box furnace to 1100-1600°C and keep warm for 3-8 hours, take out after natural cooling, and then crush to obtain red phosphor.

[0049] Preferably, the red fluorescent powder is prepared by the following method: weighing zinc oxide powder, gallium trioxide powder and chromium trioxide powder according to the structural formula, mixing the above-mentioned raw materials after weighing, and placing them in a high-temperature box furnace Raise the temperature to 1500°C and keep it warm for 6 hours, take it out after natural cooling, and then crush it to obtain red phosphor

[0050] The raw materials for preparing silicate glass powder in the present invention include silicon di...

Embodiment 1

[0065] Weigh the red fluorescent powder and silicate glass powder at a mass ratio of 5:95, mix them evenly in agate agate, then take 0.5g of the mixture in a mold, press it into a sheet at 30MPa, and then place it in a high-temperature box-type resistor In the furnace, the temperature was raised to 680 °C at 5 °C / min, and then kept for 0.5 h. After the reaction, the furnace was cooled to room temperature. After cutting, grinding and polishing, a far-red fluorescent glass ceramic with a thickness of 0.5 mm was obtained.

[0066] The far-red fluorescent glass ceramic is fixed on the high-power blue LED chip to obtain the LED plant lamp.

Embodiment 2

[0068] Weigh the red fluorescent powder and silicate glass powder at a mass ratio of 10:90, mix them evenly in agate agate, then take 0.5g of the mixture in a mold, press it into a sheet at 30MPa, and then place it in a high-temperature box-type resistor In the furnace, the temperature was raised to 680 °C at 5 °C / min, and then kept for 0.5 h. After the reaction, the furnace was cooled to room temperature. After cutting, grinding and polishing, a far-red fluorescent glass ceramic with a thickness of 0.5 mm was obtained.

[0069] The far-red fluorescent glass ceramic is fixed on the high-power blue LED chip to obtain the LED plant lamp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com