High-rate anti-expansion lithium titanate material and preparation method thereof

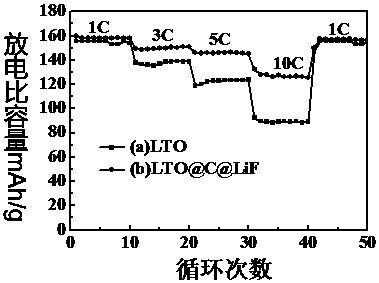

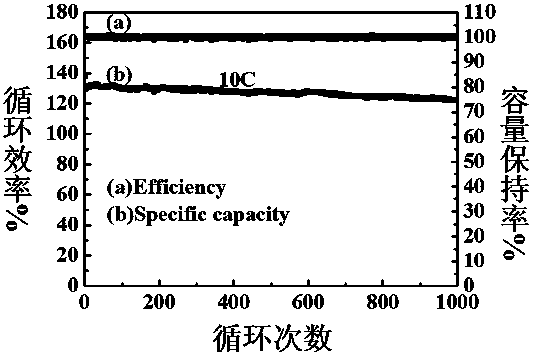

A gas lithium titanate, high-rate technology, applied in the field of high-rate anti-flatulence lithium titanate materials and its preparation, can solve the problems of lithium titanate rate and flatulence at the same time, and achieve low cost and high lithium ion migration rate , the effect of reducing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the high-magnification anti-flatulence lithium titanate material in this embodiment, the specific steps are as follows:

[0026] (1) One-step preparation of carbon-coated lithium titanate (LTO@C)

[0027] Weigh titanium dioxide, lithium carbonate and glucose according to the mass ratio of 1:0.37:0.14, mix with 1% polyvinylpyrrolidone solution to obtain a uniform slurry, dry at 80°C, and roast at 600°C for 12h under the protection of argon to obtain the LTO@C material.

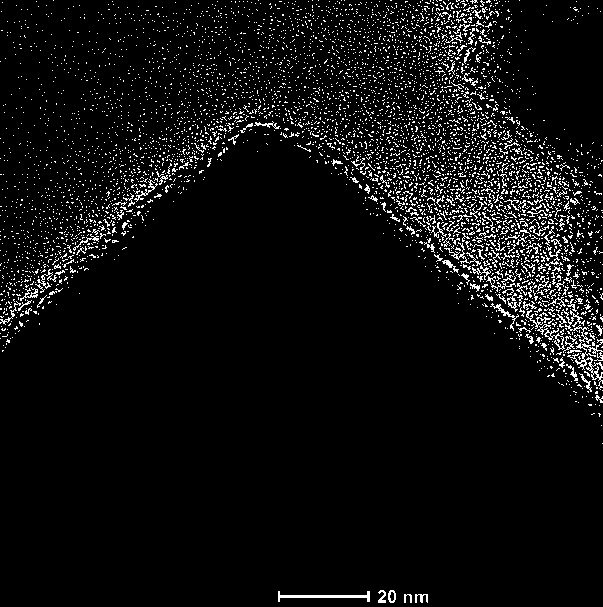

[0028] (2) Preparation of lithium fluoride carbon co-coated lithium titanate material (LTO@C@LiF)

[0029] Weigh 1g of LTO@C, add 10g of water and ultrasonically disperse evenly, weigh 0.0427g of lithium carbonate and add it under mechanical stirring conditions, then weigh 0.0428g of ammonium fluoride and dissolve it in the beaker, add it dropwise to the above suspension, stir , in a water bath at 80°C, and dried to obtain the LTO@C@LiF precursor, which was calcined in argon at...

Embodiment 2

[0031] The preparation method of the high-magnification anti-flatulence lithium titanate material in this embodiment, the specific steps are as follows:

[0032] (1) One-step preparation of carbon-coated lithium titanate (LTO@C)

[0033] Weigh titanium dioxide, lithium carbonate and glucose according to the mass ratio of 1:0.37:0.20, mix them with 0.5% polyvinylpyrrolidone solution to obtain a uniform slurry, dry at 80°C, and roast at 700°C for 15 hours under the protection of nitrogen to obtain LTO@C materials.

[0034] (2) Preparation of lithium fluoride carbon co-coated lithium titanate material (LTO@C@LiF)

[0035] Weigh 1g of LTO@C, add 10g of water and ultrasonically disperse evenly, weigh 0.0641g of lithium carbonate and add it under mechanical stirring conditions, then weigh 0.0642g of ammonium fluoride and dissolve it in the beaker, add it dropwise to the above suspension, stir , in a water bath at 80°C, evaporated until the solution was evaporated to dryness, and dr...

Embodiment 3

[0037] The preparation method of the high-magnification anti-flatulence lithium titanate material in this embodiment, the specific steps are as follows:

[0038] (1) One-step preparation of carbon-coated lithium titanate (LTO@C)

[0039] According to the mass ratio of 1:0.38:0.16, titanium dioxide, lithium carbonate and sucrose were weighed and mixed, 1.5% polystyrene solution was added to mix to obtain a uniform slurry, dried at 80°C, and calcined at 800°C for 10 h under the protection of helium to obtain LTO@C materials.

[0040] (2) Preparation of lithium fluoride carbon co-coated lithium titanate material (LTO@C@LiF)

[0041]Weigh 1g of LTO@C, add 15g of ethanol to ultrasonically disperse evenly, weigh 0.0185g of lithium hydroxide and add it under mechanical stirring conditions, then weigh 0.0285g of ammonium fluoride and dissolve it in a beaker, and add it dropwise to the above suspension. Stir, 80 ℃ water bath, evaporate until the solution is evaporated to dryness, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com