Fully-dense block-shaped anisotropy nanocrystal Sm2Co7 magnet and preparation method thereof

An anisotropic, nanocrystalline technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of long production cycle, poor product consistency, complex process, etc., to achieve low cost and short production cycle , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Smelting Sm with a purity greater than 99.9% and Co metal with a purity greater than 99.9% in a suspension furnace to smelt the master alloy, Sm 2 co 7 The composition adopted by the magnet is that the mass ratio of Sm is 44.52%, and the mass ratio of Co is 55.48% (Sm is equivalent to Sm 2 co 7 Sm in excess of 10%)). The master alloy was rapidly quenched to obtain a rapidly quenched strip, and then the high-energy ball milling method was used for 5 hours under the protection of argon with a purity of 99.999%, and the Sm 2 co 7 Ingot ball milled into Sm 2 co 7 Amorphous powder;

[0017] 2) After the amorphous alloy powder is loaded into the tungsten carbide cemented carbide mold, rapid hot-pressing treatment is performed to obtain fully dense isotropic nanocrystalline Sm 2 co 7 For magnets, the process parameters of rapid hot pressing are: under the pressure of 500Mpa, the temperature is raised from room temperature to 650°C at a heating rate of 50°C / min, with...

Embodiment 2

[0021] 1) Smelting Sm with a purity greater than 99.9% and Co metal with a purity greater than 99.9% in a suspension furnace to smelt the master alloy, Sm 2 co 7 The composition used for the magnet was 44.52% by mass of Sm and 55.48% by mass of Co. Rapidly quench the master alloy to obtain rapidly quenched thin strips, and then use high-energy ball milling method for 5 hours under the protection of argon with a purity of 99.999%, and the Sm 2 co 7 Ingot ball milled into Sm 2 co 7 Amorphous powder;

[0022] 2) After the amorphous alloy powder is loaded into the tungsten carbide cemented carbide mold, rapid hot-pressing treatment is performed to obtain fully dense isotropic nanocrystalline Sm 2 co 7 For magnets, the process parameters of rapid hot pressing are as follows: under a pressure of 500Mpa, at a heating rate of 50°C / min, the temperature is raised from room temperature to 650°C, and the temperature is kept for 10 minutes;

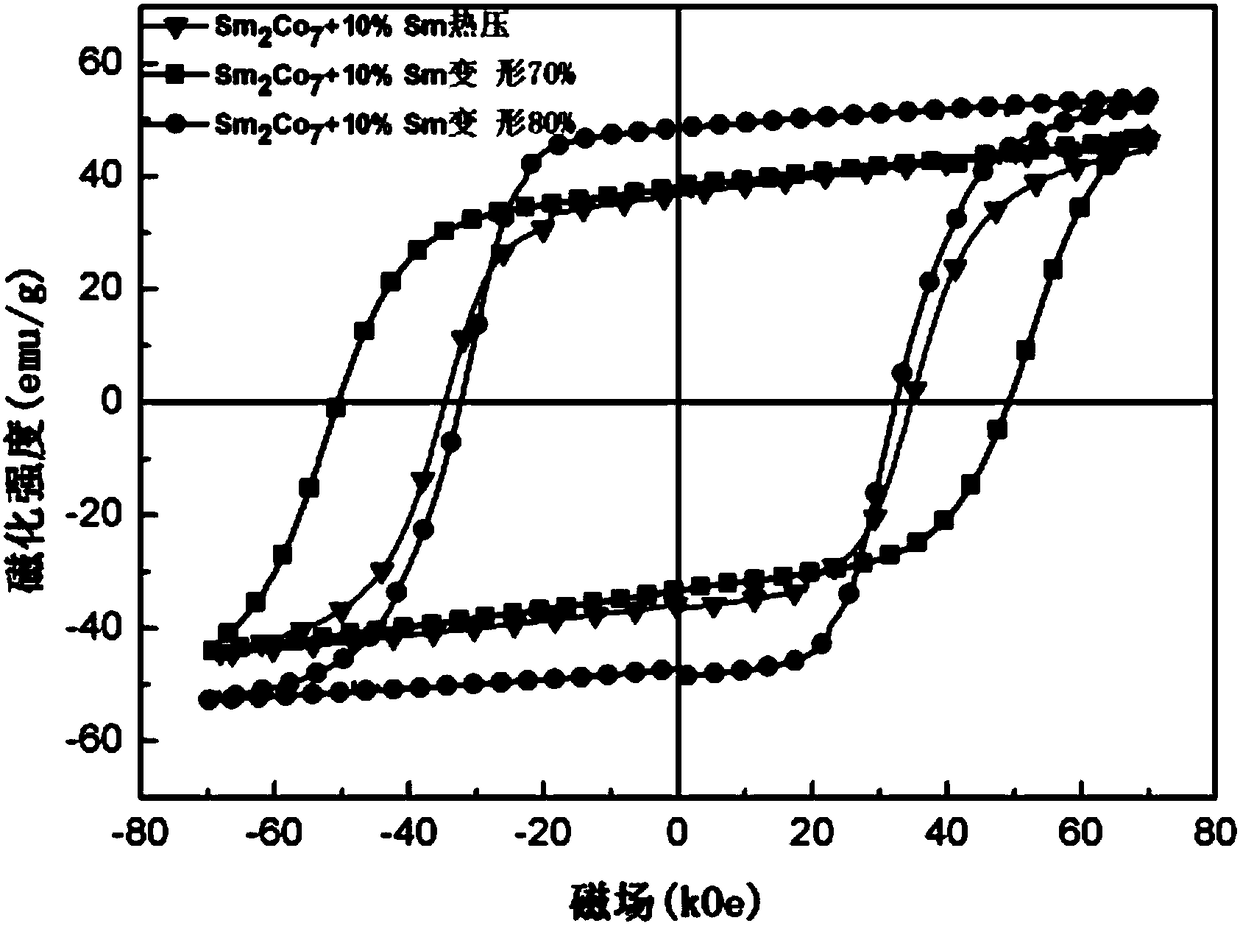

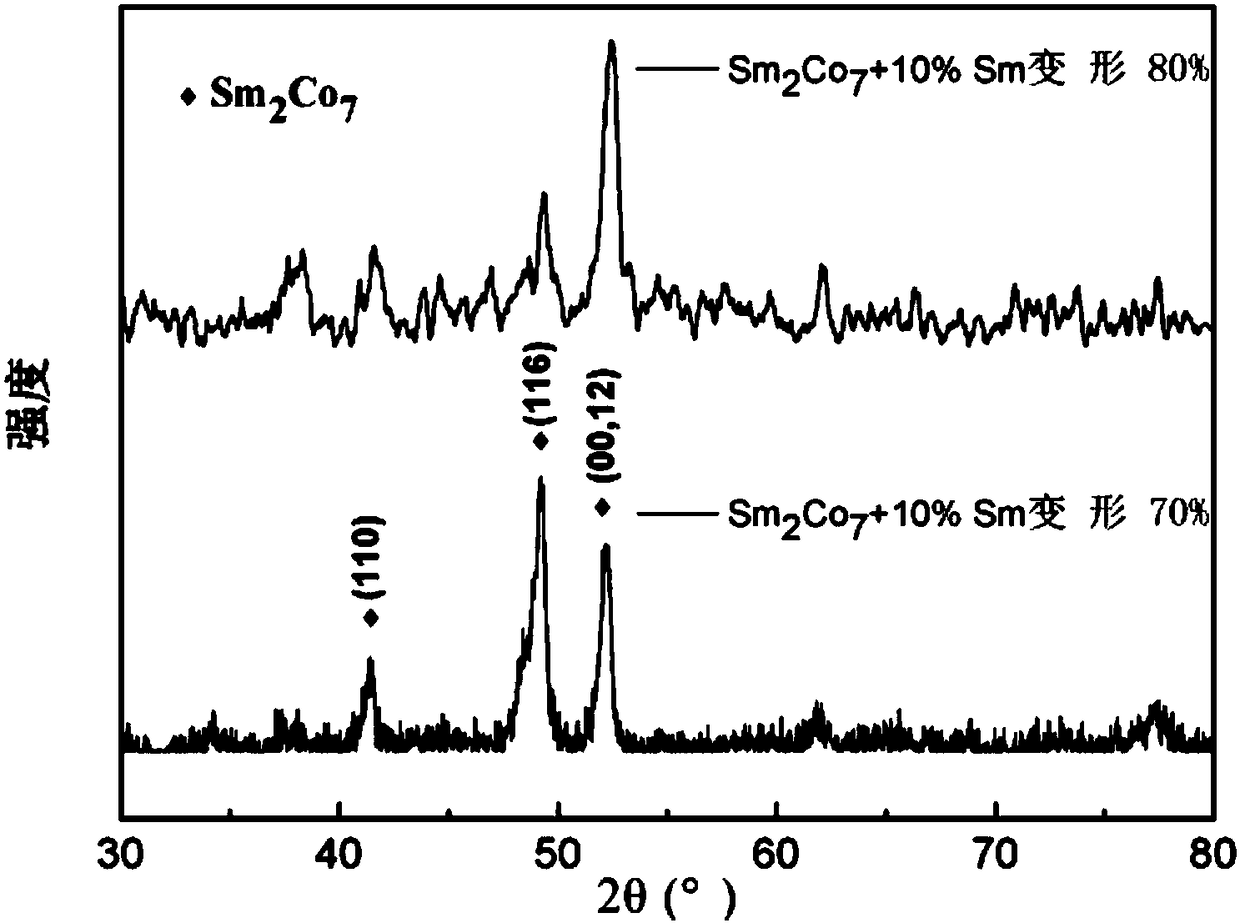

[0023] 3) For fully dense isotropic Sm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com