Film preparation method for improving application frequency of film through stress induction

A thin-film preparation and thin-film technology is applied in the field of preparation of using stress induction to increase the application frequency of soft magnetic thin films, and can solve the problems of inability to take into account high magnetic permeability and high application frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A thin film preparation method for increasing the application frequency of the thin film by stress induction, specifically comprising the following steps:

[0024] Step 1. Turn on the main power supply and the switches of each part of the electron beam evaporation system, turn on the water cooler, mechanical pump, molecular pump, film thickness meter, and electron gun in turn to preheat the equipment;

[0025] Step 2. Clean the polyimide flexible substrate with absolute ethanol, and dry it for later use;

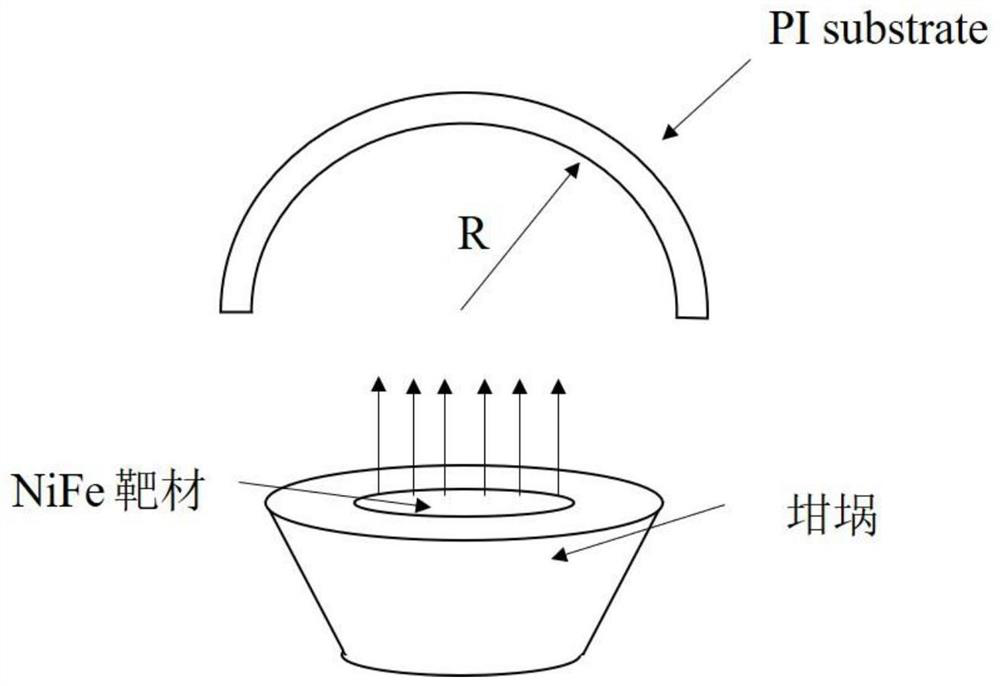

[0026] Step 3. Put the NiFe alloy target into the water-cooled crucible in the vacuum chamber, put the cleaned polyimide flexible substrate into the high vacuum electron beam evaporation system, and fix the flexible substrate on the sample holder after bending. The semicircle formed by the flexible substrate has a radius of 6 mm and is concave;

[0027] Step 4. Use a high vacuum electron beam evaporation system to deposit a thin film, and evacuate to 1.3×10 -4 Pa, s...

Embodiment 2

[0031] Compared with Embodiment 1, this embodiment differs in that in step 3, the radius of the semicircle formed by the bent flexible substrate is 9 mm.

Embodiment 3

[0033] Compared with Embodiment 1, this embodiment differs in that in step 3, the radius of the semicircle formed by the bent flexible substrate is 12 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com