Film preparation method for improving application frequency of film

A thin film preparation and thin film technology, which is applied in the field of preparation of increasing the application frequency of NiFe thin films, can solve problems such as low magnetic permeability, and achieve the effect of high magnetic permeability and high application frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

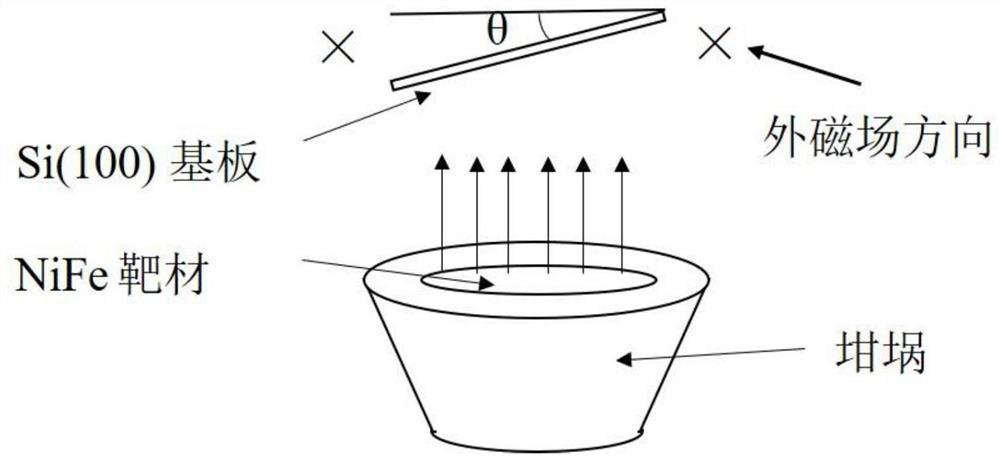

[0026] A thin film preparation method for increasing the application frequency of the thin film, specifically comprising the following steps:

[0027] Step 1. Turn on the main power supply and the switches of each part of the electron beam evaporation system, turn on the water cooler, mechanical pump, molecular pump, film thickness meter, and electron gun in turn to preheat the equipment;

[0028] Step 2, ultrasonically clean the Si(100) substrate with a size of 5mm×5mm in acetone, ethanol, and deionized water for 15 minutes in sequence, and dry it for later use;

[0029] Step 3. Put the NiFe target into the water-cooled crucible in the vacuum chamber, place the substrate on the sample holder, fix one end of the substrate on the sample holder, and lift the other end so that the substrate and the sample holder are at 5°. A permanent magnet is used to apply a magnetic field with a magnitude of 104Oe and a direction parallel to the edge of the substrate fixed on the sample holder...

Embodiment 2

[0034] Compared with Embodiment 1, this embodiment differs in that: in step 3, the angle between the substrate and the sample holder is 10°. All the other steps are the same as in Example 1.

Embodiment 3

[0036] Compared with Embodiment 1, this embodiment differs in that: in step 3, the angle between the substrate and the sample holder is 15°. All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com