Core-shell structured nanofibers prepared from gel-like oil-in-water type emulsion by electrospinning and method

An oil-in-water emulsion and electrospinning technology, which is applied in electrospinning, fiber treatment, fiber chemical characteristics, etc., can solve the problems of unsuitable hydrophobic drug loading, lack of cell biological functionality, and unsatisfactory repair effect , to achieve good biocompatibility and safety in use, low cost and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Dissolve 2.5g of gelatin in 10mL of 40% acetic acid solution, magnetically stir until completely dissolved, add 2mL of corn oil into the gelatin acetic acid solution under magnetic stirring, then shear at 6000rpm for 2min at high speed, and then use 250W Ultrasound at the highest power for 3 minutes to obtain a uniformly mixed gel-like oil-in-water emulsion.

[0046] The electrospinning device was used for spinning, and the specification of the electrospinning syringe was 2.5mL, and the needle was flat, 20G. The voltage is 15kV, the flow rate is 0.5mL / h, and the distance is 10cm. It is received by a drum. After completion, a gel-like oil-in-water emulsion electrospun nanofiber with a core-shell structure is obtained.

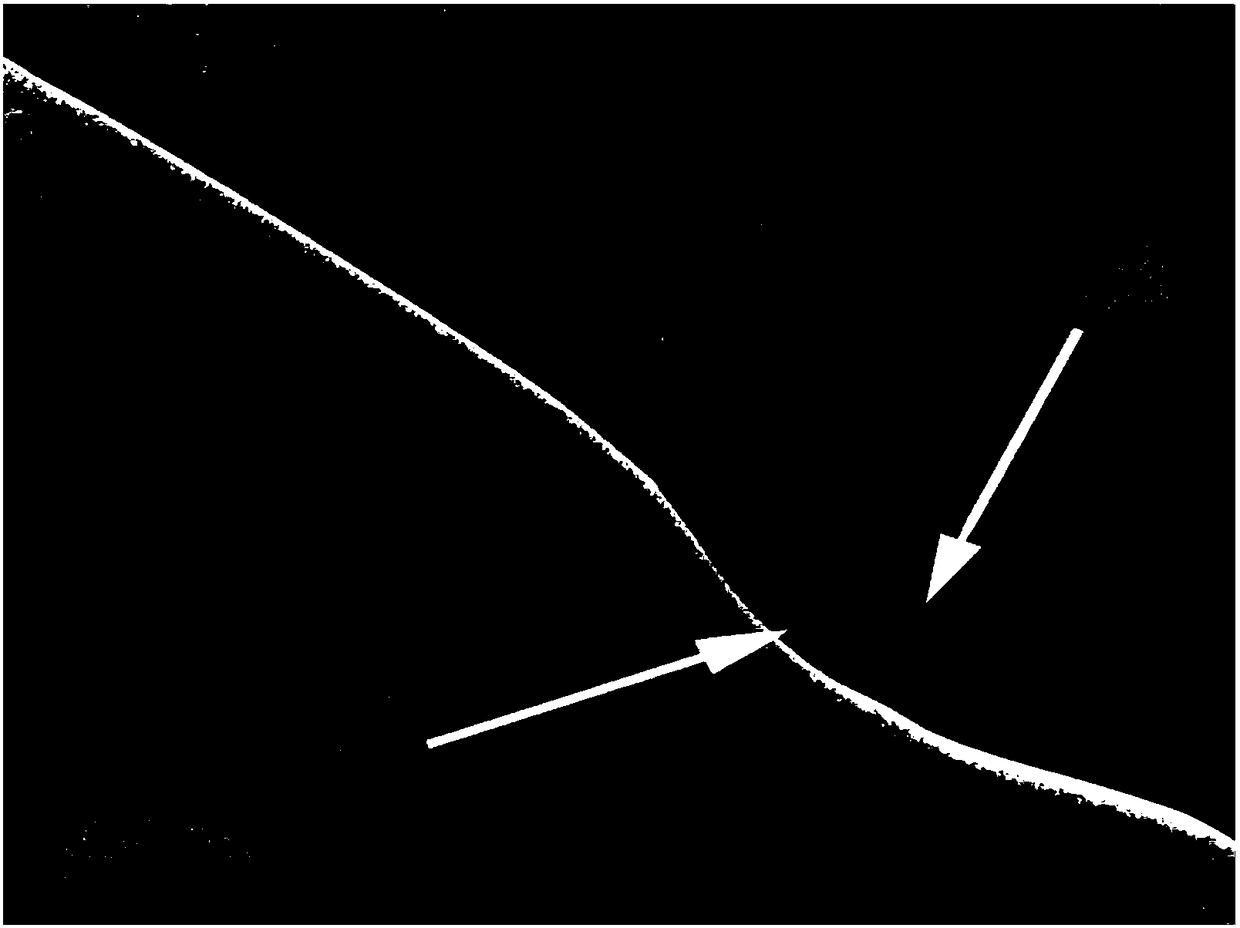

[0047] Such as figure 1 As shown, the bead-like structures are randomly distributed on the nanofibers, and the diameter of the fibers is about 180-250 nm. The fibers have a core-shell structure, such as figure 2 shown.

Embodiment 2

[0049] Dissolve 2.5g of gelatin in 10mL of 40% acetic acid solution, magnetically stir until completely dissolved, add 4mL of corn oil into the gelatin acetic acid solution under magnetic stirring, then shear at a high speed of 6000rpm for 2min, and then use 250W Ultrasound at the highest power for 3 minutes to obtain a uniformly mixed gel-like oil-in-water emulsion.

[0050] The electrospinning device was used for spinning, and the specification of the electrospinning syringe was 2.5mL, and the needle was flat, 20G. The voltage is 15kV, the flow rate is 0.5mL / h, and the distance is 10cm. It is received by a drum. After completion, a gel-like oil-in-water emulsion electrospun nanofiber with a core-shell structure is obtained.

[0051] Such as image 3 As shown, with the increase of the oil phase ratio, the fiber diameter increases to 210-330nm, and the oil loading capacity of the fiber increases.

Embodiment 3

[0053] Dissolve 2.5g of gelatin in 10mL of 40% acetic acid solution, magnetically stir until completely dissolved, add 6mL of corn oil into the gelatin acetic acid solution under magnetic stirring, then shear at a high speed of 6000rpm for 2min, and then use 250W Ultrasound for 3 minutes at the highest power, and then add 5 mL of 25% aqueous gum arabic solution to adjust the pH to 3.5, and mix well to obtain a gel-like oil-in-water emulsion. The electrospinning device was used for spinning, and the specification of the electrospinning syringe was 2.5mL, and the needle was flat, 20G. The voltage is 15kV, the flow rate is 0.5mL / h, and the distance is 10cm. It is received by a drum. After completion, a gel-like oil-in-water emulsion electrospun nanofiber is obtained.

[0054] Such as Figure 4 As shown, the fibers tend to be uniform, with a diameter of about 410-770nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com