A nitrogen-doped ordered mesoporous carbon catalytic material and its preparation method and application

A catalytic material and mesoporous carbon technology, which is applied in chemical instruments and methods, carbon preparation/purification, separation methods, etc., can solve problems such as difficult industrial production, high synthesis technology requirements, and complicated preparation methods of mesoporous carbon materials. It achieves the effects of improving surface alkalinity, broad application prospects, and simple and green preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Weigh 2g of P123, 0.4g of m-aminophenol and 0.6g of terephthalaldehyde and grind them evenly in a mortar, transfer the above solid mixture into a 100ml autoclave, perform hydrothermal treatment at 150°C for 12h, then cool naturally at room temperature, grind finely, Roast to remove the template, pre-oxidize in air atmosphere at 250°C for 2 hours, rapidly carbonize at 700°C in nitrogen atmosphere for 15 minutes, etch and carbonize in KOH at 700°C in nitrogen atmosphere for 2 hours, neutralize with hydrochloric acid, wash with water until neutral drying to obtain the final product nitrogen-containing medium Pore carbon N-OMC, and named N-OMC-700.

Embodiment 2

[0045] Embodiment 2 (best embodiment)

[0046] Weigh 2g of F127, 0.4g of m-aminophenol and 0.6g of terephthalaldehyde and grind them evenly in a mortar, transfer the above solid mixture into a 100ml autoclave, perform hydrothermal treatment at 150°C for 12h, cool naturally at room temperature, and grind finely. Roast to remove the template, pre-oxidize in air atmosphere at 250°C for 2 hours, rapidly carbonize at 800°C in nitrogen atmosphere for 15 minutes, etch and carbonize in KOH at 800°C in nitrogen atmosphere for 2 hours, neutralize with hydrochloric acid, wash with water until neutral drying to obtain the final product nitrogen-containing media Porous carbon N-OMC, and named N-OMC-800.

Embodiment 3

[0048] Weigh 2g of F108, 0.4g of m-aminophenol and 0.6g of terephthalaldehyde and grind them evenly in a mortar, transfer the above solid mixture into a 100ml autoclave, perform hydrothermal treatment at 150°C for 12h, then cool naturally at room temperature, grind finely, Roasting to remove the template, pre-oxidation in air atmosphere at 250°C for 2 hours, rapid carbonization at 900°C in nitrogen atmosphere for 15 minutes, etching and carbonization in KOH at 900°C in nitrogen atmosphere for 2 hours, neutralization with hydrochloric acid, washing with water until neutral drying to obtain the final product nitrogen-containing medium Pore carbon N-OMC, and named N-OMC-900.

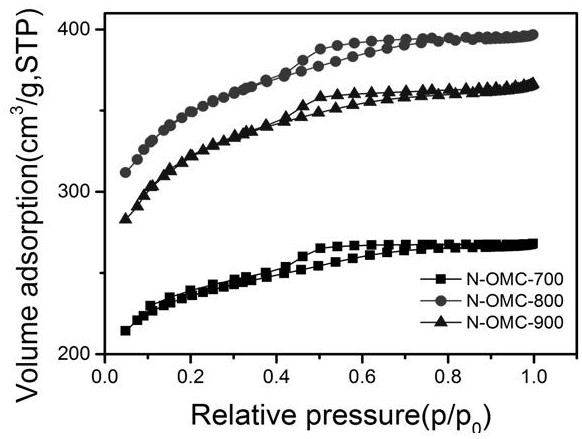

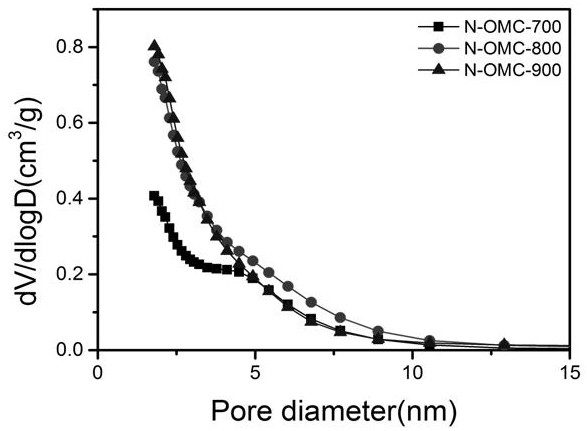

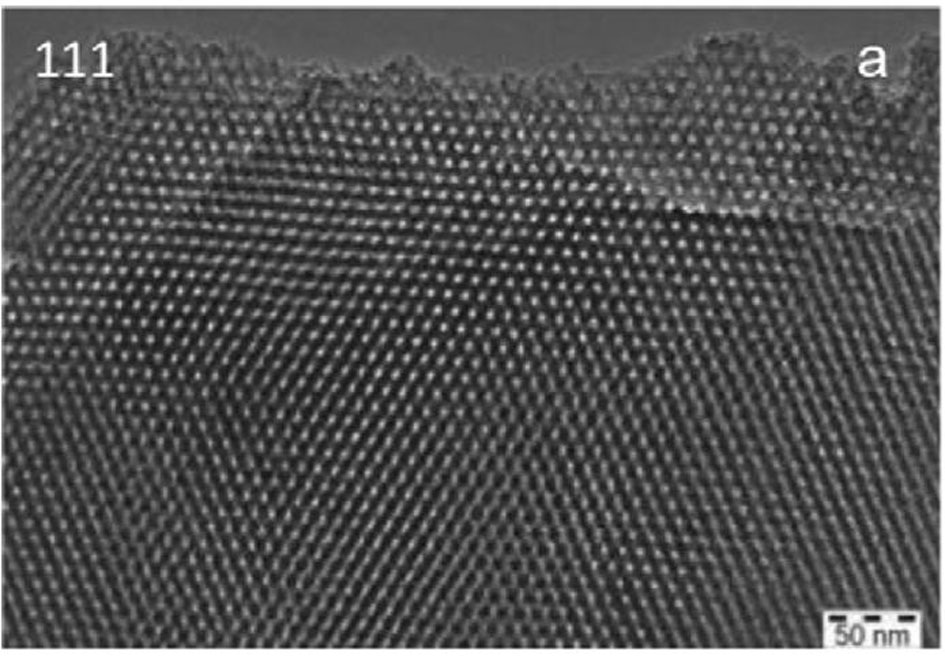

[0049] Characterization analysis is carried out to the product that embodiment 1-3 makes:

[0050] 1) N 2 Physical adsorption: The specific surface area and pore size of the sample were measured at liquid nitrogen temperature (77K) using the ASAP2020 analyzer from Micrometric Company of the United States...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com