Method of comprehensively recovering lead and zinc in high mud carbonate lead-zinc oxide ores

A carbonate-type, lead-zinc oxide technology, applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of high lead-zinc mutual content rate, difficult separation, lead-zinc separation difficulty, etc., to shorten the processing time process, energy consumption avoidance, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

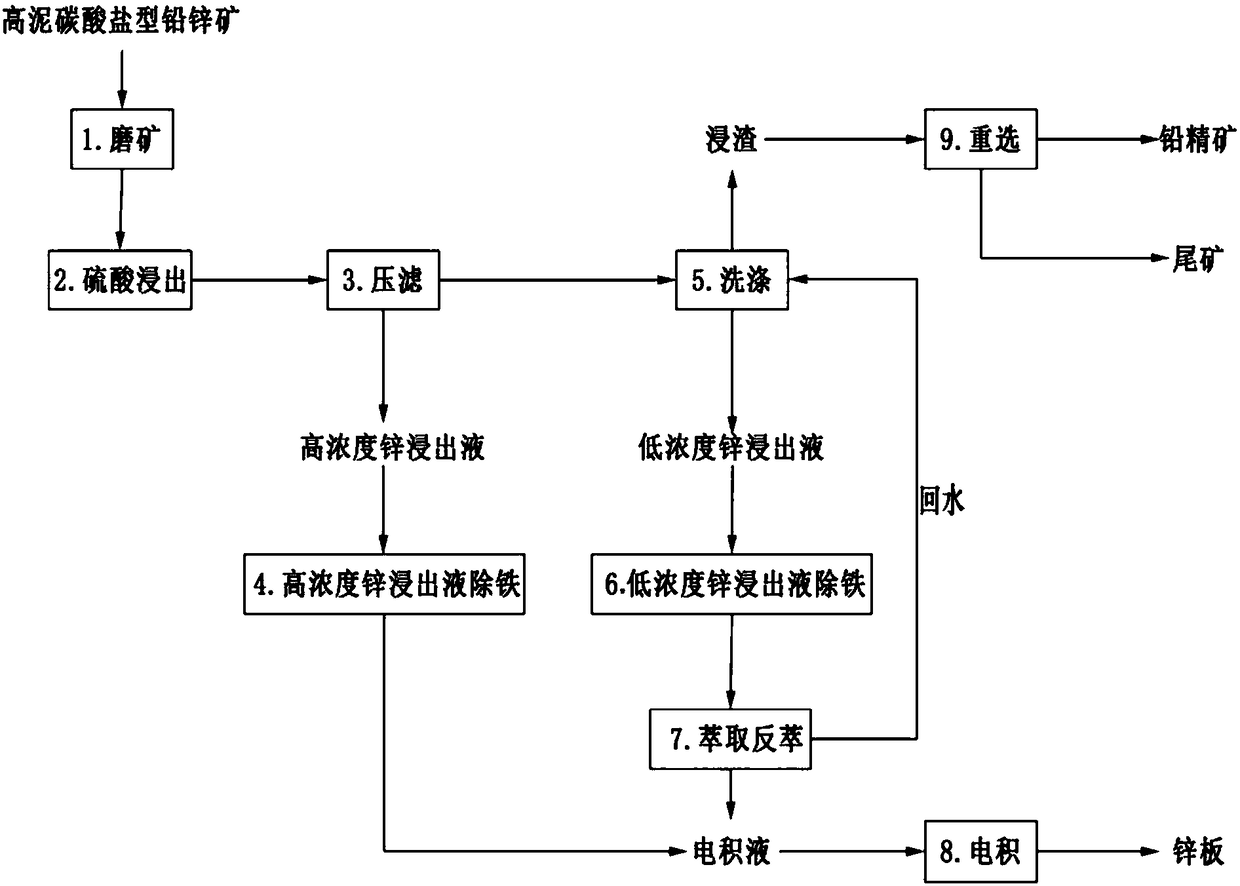

[0029] Such as figure 1 It shows that a lead-zinc ore in Xinjiang belongs to high-mud carbonate-type lead-zinc ore, with a zinc grade of more than 33% and a lead grade of about 7%. figure 1 Shown:

[0030] (1) Grinding: Grinding fineness of high mud carbonate type lead-zinc ore to -200 mesh 60%;

[0031] (2) Sulfuric acid leaching: Sulfuric acid leaching of high-sludge-containing carbonate-type lead-zinc ores, pulp concentration 30wt%, temperature 50°C, zinc ions in the leach solution obtained are 110g / L, and lead is mainly retained in the form of white lead ore. In the acid leaching residue, the total iron ion concentration is 6g / L, the pH is controlled between 1.3 and 1.8, and the zinc leaching rate is about 99%;

[0032] (3) Pressure filtration: press filtration leaching residue to directly obtain high-concentration zinc leachate;

[0033] (4) Iron removal by high-concentration zinc leaching solution: add zinc powder equivalent to 1.6 times of ferric iron to the high-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com