Photocathode based on novel nanostructure and preparation method thereof

A nanostructure and photocathode technology, which is applied in the manufacture of light-emitting cathodes, photoemission cathodes, nanotechnology for materials and surface science, etc., can solve problems such as reducing the emission current, achieve lower thresholds, enhance local electric fields, and conduct electricity. The effect of high sex and electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

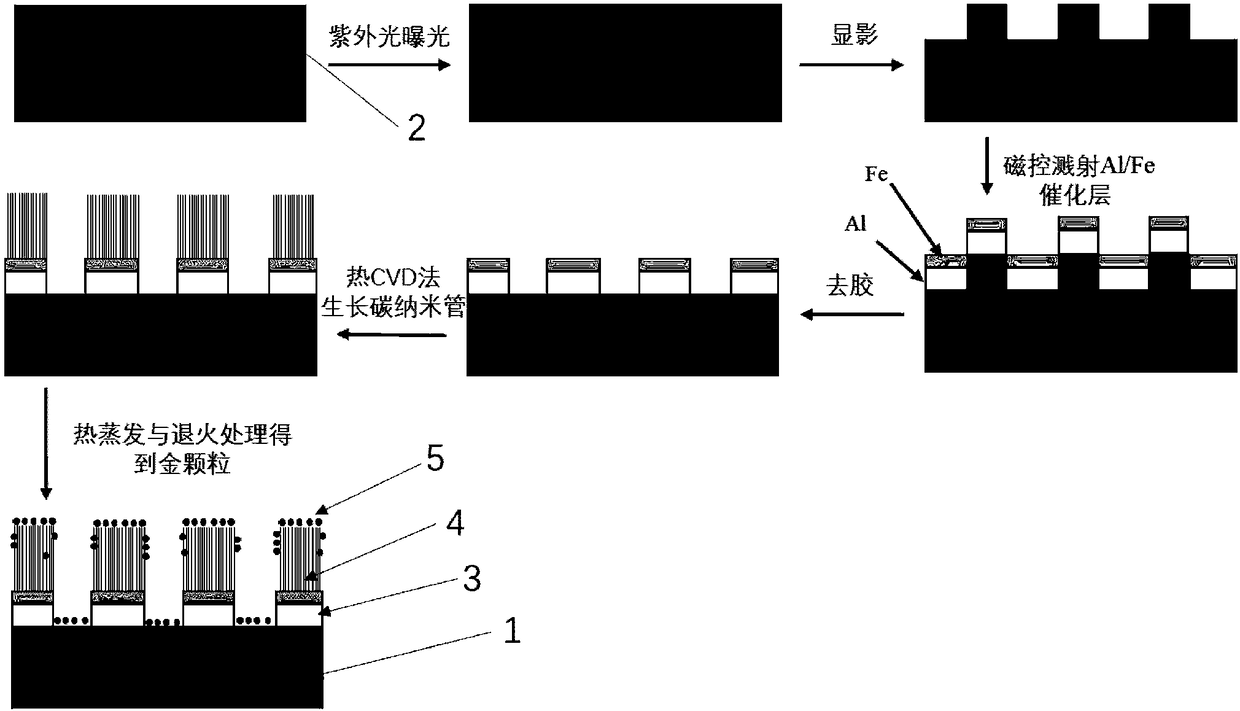

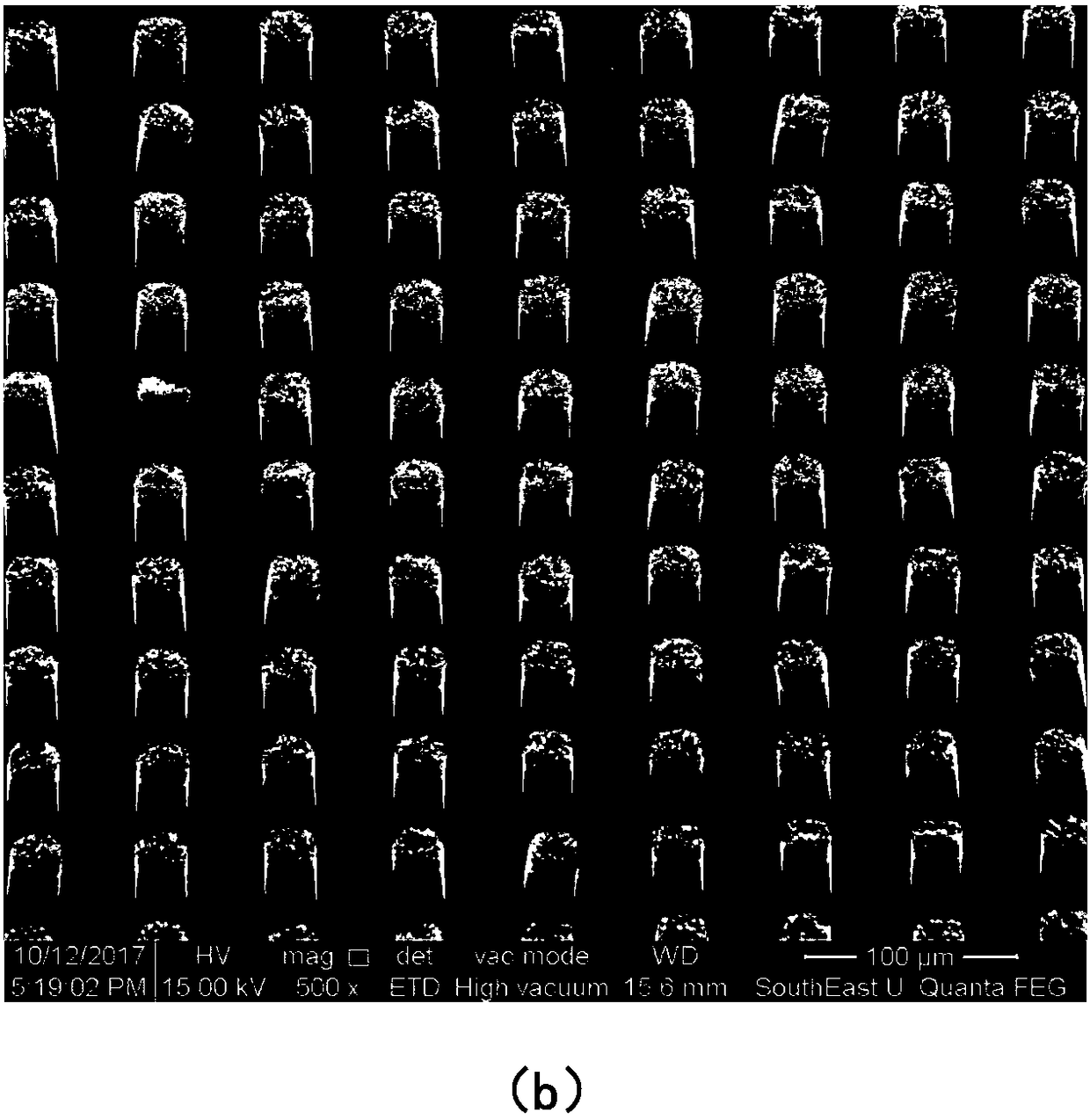

[0032] see Figure 1 to Figure 3 , the present invention provides a novel nanostructured photocathode, the novel nanostructured photocathode is formed on a substrate 1, the novel nanostructured photocathode comprises a patterned catalytic layer 3, a catalyst layer formed on the catalytic layer 3 Patterned carbon nanotubes 4 and modified metal particles 5 formed on the carbon nanotubes 4 . In addition, the lower surface of the substrate 1 is coated with conductive silver paste or gallium indium solder as a cathode electrode.

[0033] In this embodiment, the material of the substrate 1 is preferably a heavily doped n-type silicon wafer, but it is not limited thereto, and may also be, for example, other types of silicon wafers or a quartz substrate with a transparent conductive layer. The lower surface of the substrate 1 is coated with conductive silver paste or gallium indium solder as a cathode electrode, and the anode uses indium tin oxide (ITO) transparent conductive glass o...

Embodiment 2

[0039] The invention provides a preparation method for the novel nanostructure photocathode of the present invention, see Figure 1 to Figure 3 , the nanostructured photocathode of the present invention is prepared on a substrate material, such as a silicon wafer or a quartz substrate with a transparent conductive layer. In this embodiment, the substrate material is a heavily doped n-type silicon wafer , its specific preparation method is as follows:

[0040] (1) Cleaning of the silicon substrate:

[0041] For example, immerse in diluted HF solution to remove surface oxides, and then use acetone, alcohol and deionized water to clean the surface sequentially with ultrasonic cleaning.

[0042] (2) Photolithography:

[0043] Use a spin coater to pre-rotate the photoresist (positive resist) at 1000r / min for 15s, then pre-rotate at 5000r / min for 60s; bake the spin-coated silicon wafer at 110°C for 90s before cooling; put the mask plate (see figure 2 (a)) Cover the photoresist ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com