Carbon-based binderless composite material as well as preparation method and application thereof

A binder-free, composite material technology, used in carbon preparation/purification, carbon compounds, chemical instruments and methods, etc., can solve the problems of carbon fiber array performance degradation, carbon fiber array shedding, device failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

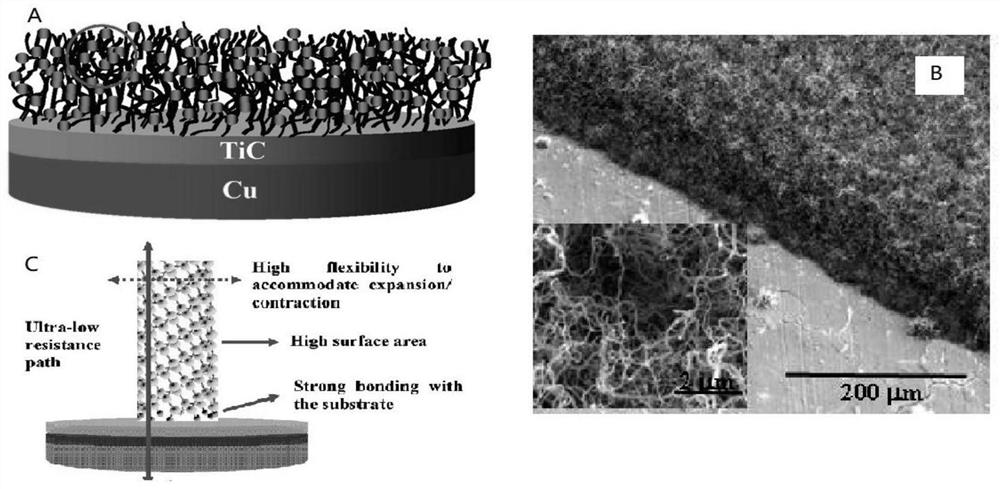

[0113] Such as Figure 4 As shown, a carbon-based binderless composite material involved in this embodiment includes a substrate (1), a carbon film (2) and structural carbon (3), and the carbon film (2) is loaded on the surface of the substrate (1), Nanostructured carbon (3) integrally formed with the carbon film (2) grows on the carbon film.

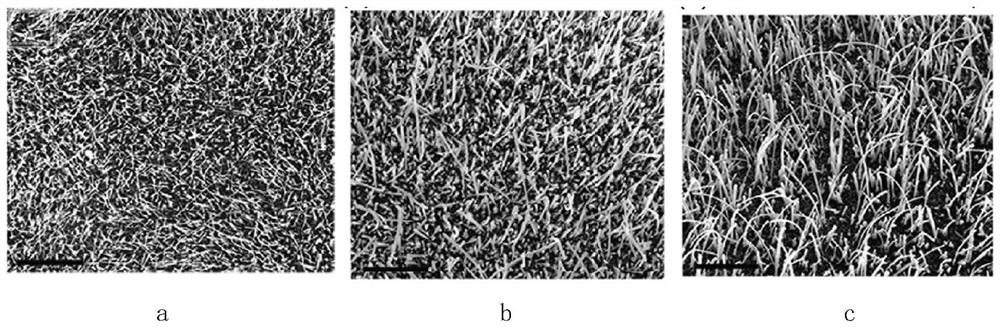

[0114] Described a kind of carbon-based binderless composite material is prepared by the following method: 1 gram of potassium carbonate (K 2 CO 3 ), sodium carbonate (Na 2 CO 3 ), lithium carbonate (Li 2 CO 3 ) and potassium fluoride (KF) were dissolved in 20 g of deionized water containing 1% surfactant to prepare a catalyst solution. Then the catalyst solutions were sprayed on 50 micron thick stainless steel foils respectively, and then the stainless steel foils were placed in a drying oven at 80° C. to dry. The dried stainless steel foil was placed in a tube furnace, and then the tube furnace was evacuated, and argon was intr...

Embodiment 2

[0117] The structure of a carbon-based binderless composite material involved in this example is the same as that of Example 1, and the specific preparation method is as follows:

[0118] 1 gram of potassium carbonate (K 2 CO 3 ), lithium carbonate (Li 2 CO 3 ) was dissolved into 20 grams of deionized water to prepare a catalyst solution. Then the catalyst solution was sprayed on copper foil with a thickness of 8 μm, aluminum foil with a thickness of 20 μm and a silicon wafer, and then placed in a drying oven at 80° C. to dry. 0.3 g K 2 CO 3 , 0.3 g Li 2 CO 3 , 0.3 g Na 2 CO 3 Prepare the catalyst solution by dissolving into 20 g of deionized water. The catalyst solution was then sprayed onto silicon wafers, which were then placed in a drying oven to dry. Place the dried copper foil, aluminum foil and silicon wafer in a tube furnace, and after the tube furnace is evacuated, argon gas is introduced. Then heat the tube furnace from room temperature to 600 °C at 10 °C...

Embodiment 3

[0120] The structure of a carbon-based binderless composite material involved in this example is the same as that of Example 1, and the specific preparation method is as follows:

[0121] Separately mix 1 gram of sodium bromide (NaBr), lithium dihydrogen phosphate (LiH 2 PO 4 ), dissolved in 20 g of deionized water with 1% surfactant to prepare a catalyst solution. The catalyst solutions were then sprayed onto 50 μm thick stainless steel foils, respectively. The stainless steel foil was dried in an oven at 80°C and then placed in a tube furnace. Then the tube furnace was evacuated, and argon was introduced. Heat the tube furnace at 10°C / min from room temperature to 650°C, and keep it warm for 30 minutes to ensure good contact and reaction between the catalyst and the surface of the substrate, the thickness of the formed carbon film will be uniform, and the morphology of the grown structural carbon will be uniform Relatively uniform. Then the furnace temperature was lowere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com