High-strength and high-temperature resistance nodular cast iron, and casting technology of nodular cast iron pipe

A ductile iron, high temperature resistant technology, applied in the field of foundry processing, can solve the problem of pipe wear resistance, structural strength, structural toughness, high temperature resistance and thermal expansion resistance, affecting the reliability and service life of cast iron pipe fittings, and pipe casting operations. Low work efficiency and other problems, to achieve the effect of improving fatigue resistance and wear resistance, reducing internal stress concentration and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

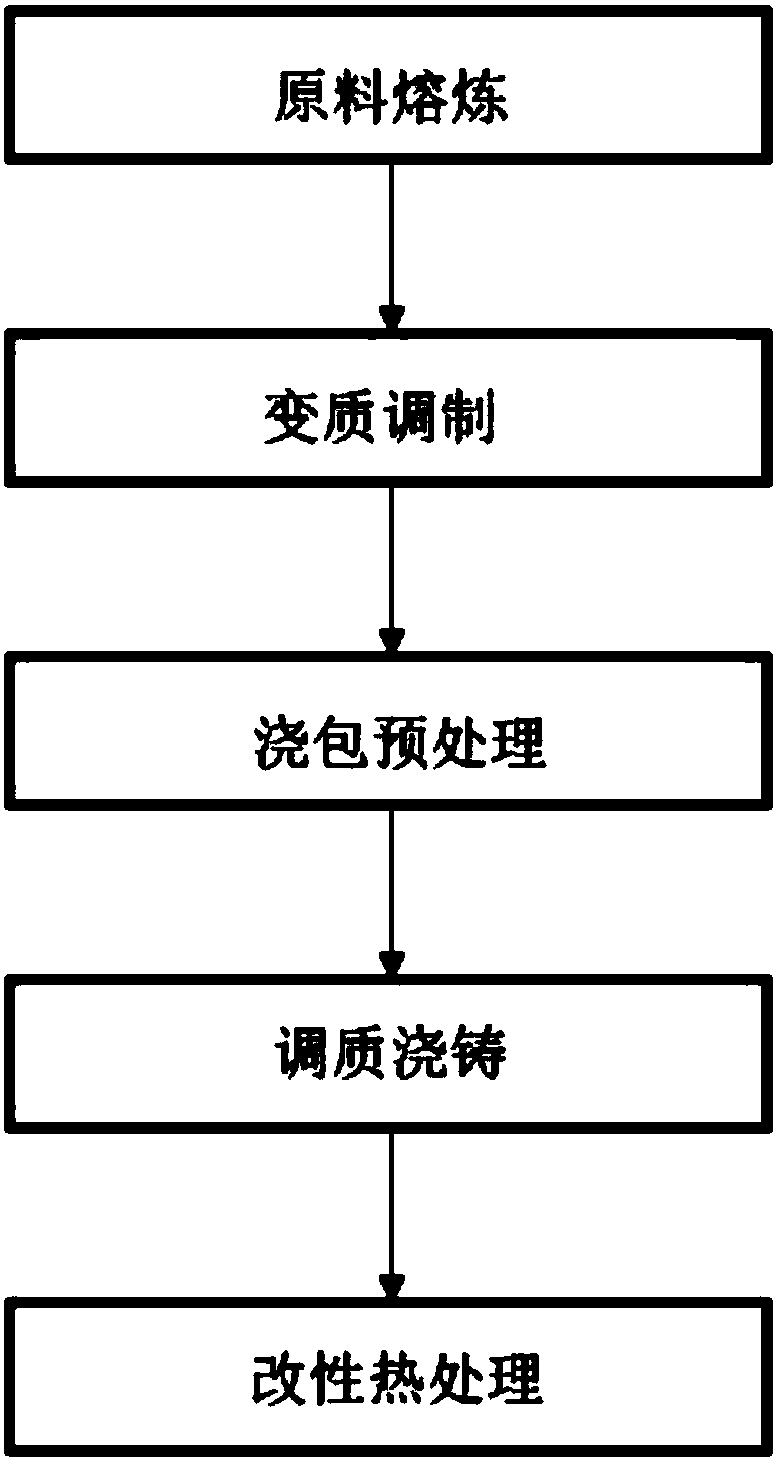

[0022] Such as figure 1 As shown, a high-strength and high-temperature-resistant ductile iron is composed of the following raw materials in parts by weight: 10% returned iron, 10% primary iron, 0.5% iron-nickel alloy, 3% manganese-ferroalloy, 5% tungsten-molybdenum alloy, carburized 1.5% agent, 2.1% modifier, 1.2% nodulizer, 2.1% inoculant, 0.5%-2% rare earth, and the balance is steel scrap.

[0023] Further, the carburizer is coke foam with a carbon content of more than 85% by weight, and the particle diameter of coke foam is ≤400nm.

[0024] Further, the modifying agent is SiC simple substance micropowder particles, and the diameter of SiC simple substance micropowder particles is ≤400nm.

[0025] Further, the rare earth is a lanthanide element including elements such as Ce, H, Dy, Sm, Gd and Lu.

[0026] Further, the chemical element content of the high-strength and high-temperature resistant nodular cast iron is C: 3.5%, Si: 2.8%, Ni: 0.3%, W: 2.5%, Mn: 1.5%, Mo: 4%, Zr:...

Embodiment 2

[0037] Such as figure 1A high-strength and high-temperature-resistant ductile iron is shown, which is composed of the following raw materials in parts by weight: 10% returned iron, 15% primary iron, 1% iron-nickel alloy, 3.5% manganese-ferro alloy, 6.5% tungsten-molybdenum alloy, and carburizer 1%, modifier 1.1%, nodulizer 1.1%, inoculant 1.5%, rare earth 0.5%, and the balance is steel scrap.

[0038] In this embodiment, the carburant is coke foam with a carbon content of more than 85% by weight, and the particle diameter of coke foam is ≤400nm.

[0039] In this embodiment, the modifying agent is SiC simple substance micropowder particles, and the diameter of SiC simple substance micropowder particles is ≤400nm.

[0040] In this embodiment, the rare earth is a lanthanide element including elements such as Ce, H, Dy, Sm, Gd and Lu.

[0041] In this embodiment, the chemical element content of the high-strength and high-temperature resistant ductile iron is C: 3.7%, Si: 5.3%, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com