Preparation method of carbon-containing high-entropy alloy composite material

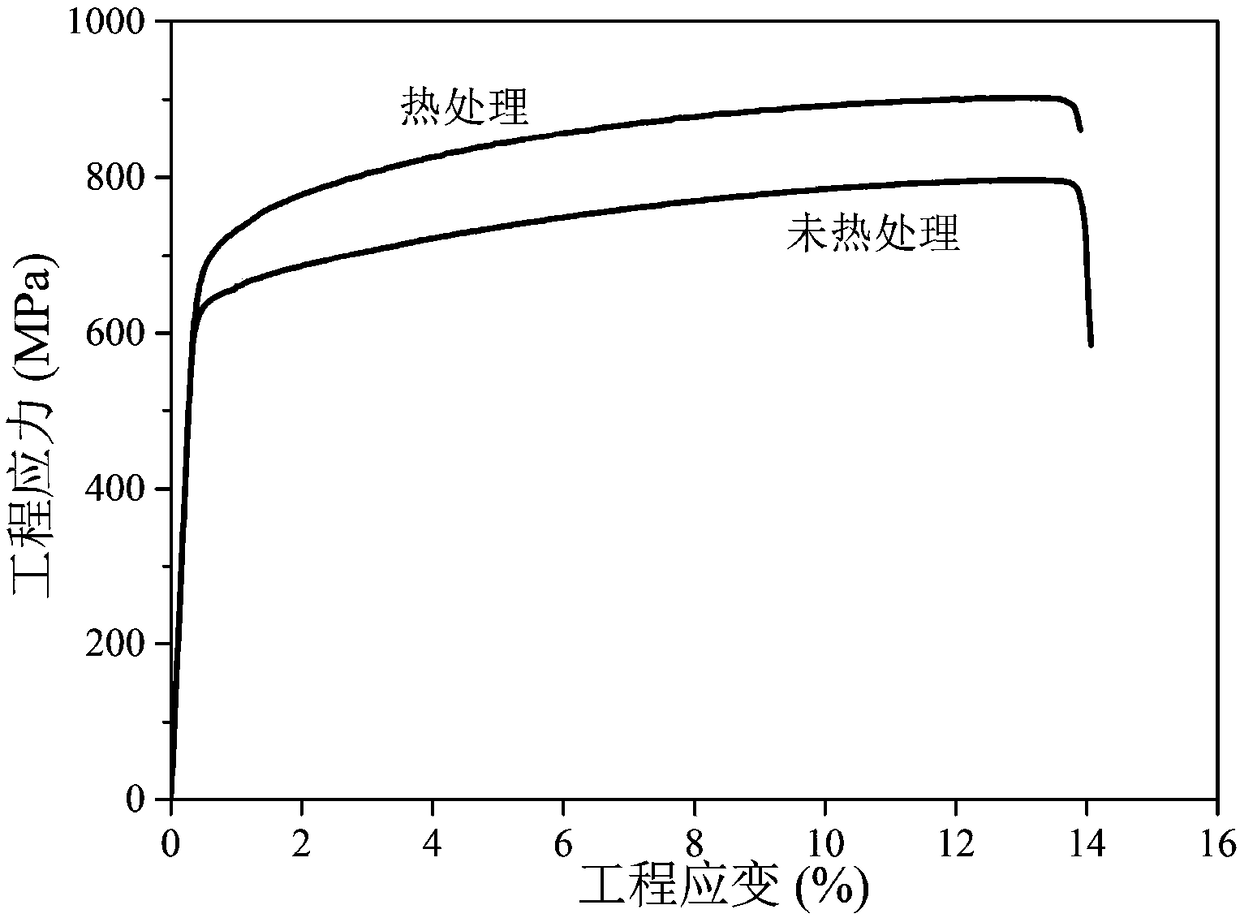

A technology of high-entropy alloys and composite materials, which can be used in additive manufacturing, additive processing, and energy efficiency improvement. , The molding speed is fast, and the effect of no loss of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention provides a method for preparing a carbon-containing high-entropy alloy composite material, which includes the following steps:

[0041] (1) Select Fe, Co, Cr, Ni metal element and chromium carbide as raw materials, the atomic ratio of Fe, Cr, Ni, Co, C in the composite material is 1:1:1:1:1:0.05, adopting gas atomization method Preparation of high-entropy pre-alloyed powder; among them, the alloying element powder does not contain other impurities except a small amount of inevitable impurity oxygen element, and the raw materials do not contain other elements except Fe, Co, Cr, Ni, C; high-entropy pre-alloyed powder The particle size range of alloy powder is 15~55μm, and D50 is controlled at 45μm;

[0042] (2) Establish a three-dimensional model of the part on the computer, plan the scanning path of the component, and use a checkerboard type to scan layer by layer; when scanning layer by layer, the deflection angle is 65°;

[0043] (3) Molding using selective las...

Embodiment 2

[0051] The invention provides a method for preparing a carbon-containing high-entropy alloy composite material, which includes the following steps:

[0052] (1) Fe, Co, Cr, Ni and chromium carbide are selected as raw materials. The atomic ratio of Fe, Cr, Ni, Co, and C in the composite material is 1:1:1:1:1:0.1, and the gas atomization method is adopted. Preparation of high-entropy pre-alloyed powder; among them, the alloying element powder does not contain other impurities except a small amount of inevitable impurity oxygen element, and the raw materials do not contain other elements except Fe, Co, Cr, Ni, C; high-entropy pre-alloyed powder The particle size range of alloy powder is 15~45μm, and d50 is controlled at 40μm;

[0053] (2) Establish a three-dimensional model of the part on the computer, plan the scanning path of the component, and use a checkerboard pattern to scan layer by layer; when scanning layer by layer, the deflection angle is 70°;

[0054] (3) The selected area ...

Embodiment 3

[0061] The invention provides a method for preparing a carbon-containing high-entropy alloy composite material, which includes the following steps:

[0062] (1) Fe, Co, Cr, Ni, Mn and chromium carbide are selected as raw materials. The atomic ratio of Fe, Cr, Ni, Co, Mn and C in the composite material is 1:1:1:1:1:1:1:0.07 , Adopt gas atomization method to prepare high-entropy pre-alloyed powder; among them, the alloying element powder does not contain other impurities except a small amount of unavoidable impurity oxygen element, and the raw materials do not contain other than Fe, Co, Cr, Ni, Mn, C The other element composition of the high-entropy pre-alloyed powder powder has a particle size range of 15-45μm, of which d50 is controlled at 35μm;

[0063] (2) Establish a three-dimensional model of the part on the computer, plan the scanning path of the component, and use a checkerboard pattern to scan layer by layer; when scanning layer by layer, the deflection angle is 63°;

[0064]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com