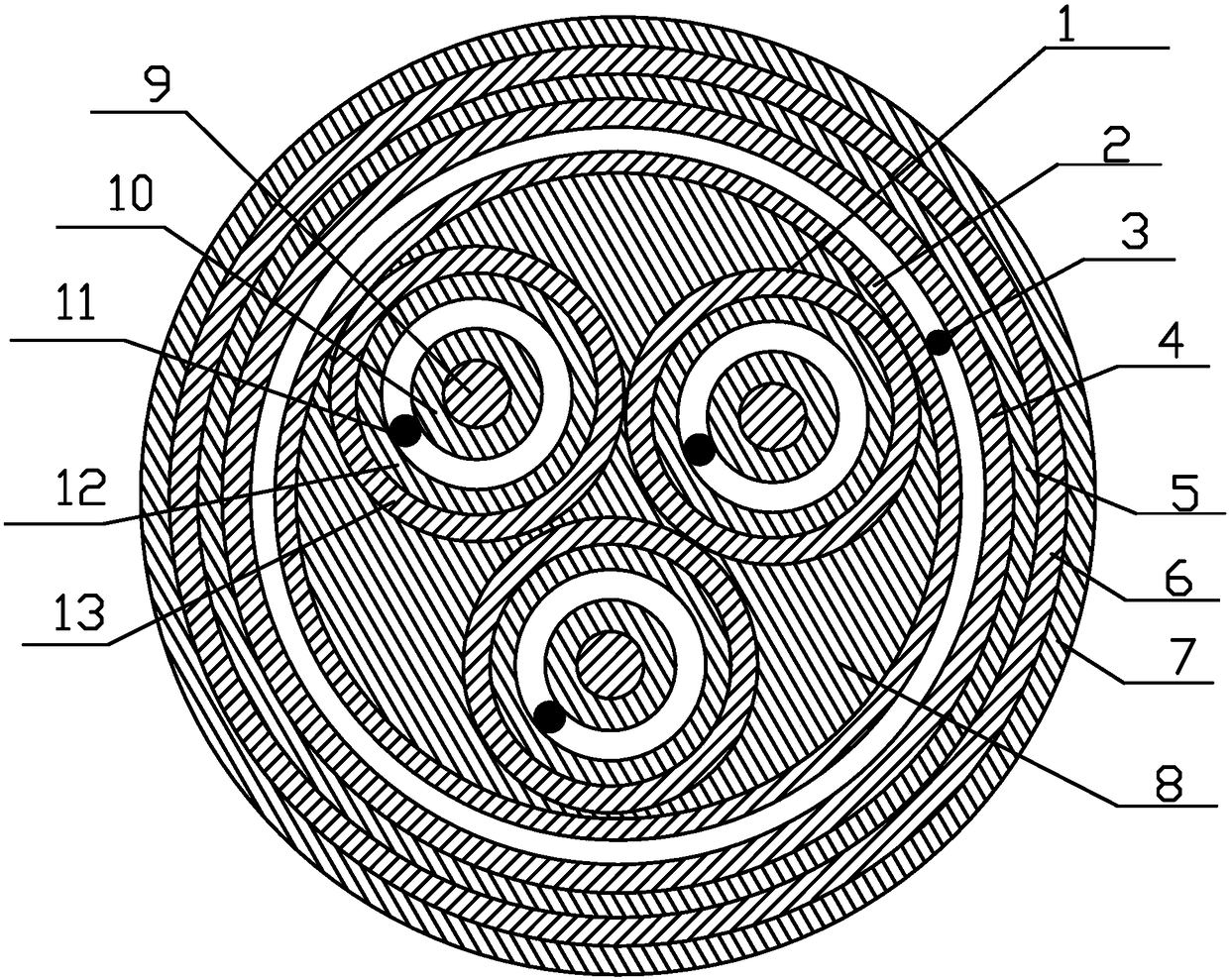

Flame-retardant fireproof marine work intrinsic safety instrument cable

An instrument cable and intrinsically safe technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of weak cable protection, large space occupied, and poor reliability in use, and achieve strong signal transmission capability, good performance, and low The effect of the possibility of danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The material of the outer sheath layer 7 is an environmentally friendly flame-retardant material, which consists of 50 parts of high-density polyethylene, 20 parts of epoxy-modified polyurethane, 3 parts of ethylene-acrylic acid magnesium ionomer, and 15 parts of active flame retardant. 1 part, 1 part of tetraerythritol ester, 2 parts of stearic acid, 3 parts of polyethylene carbon black masterbatch;

[0029]The epoxy-modified polyurethane is obtained by the following method: put 30 parts of polyether polyol into a reaction kettle, heat to 120° C. for reflux dehydration for 1 hour while stirring, and then add 35 parts of toluene diisocyanate when the temperature is lowered to 50° C., slowly Raise the temperature to 80°C, stir and react for 4-6 hours to obtain a polyurethane prepolymer; vacuum dehydrate 15 parts of diglycidyl tetrahydrophthalate at 80°C for 1-3 hours, cool down to 60°C, and Add the polyurethane prepolymer, 8 parts of 1,4-butanediol, 15 parts of trimethyl...

Embodiment 2

[0033] The material of the outer sheath layer 7 is an environmentally friendly flame retardant material. The environmentally friendly flame retardant material consists of 70 parts of high density polyethylene, 35 parts of epoxy modified polyurethane, 9 parts of ethylene-acrylic acid magnesium ionomer, 15 parts of oleic acid, sulfur Composed of 5 parts of dilauryl dicarboxylate and 10 parts of polyethylene carbon black masterbatch;

[0034] The epoxy-modified polyurethane is obtained by the following method: put 45 parts of polyether polyol into the reaction kettle, heat to 120° C. for reflux dehydration for 1 hour while stirring, then add 55 parts of toluene diisocyanate when the temperature is lowered to 50° C., slowly Raise the temperature to 80°C, stir and react for 4-6 hours to obtain a polyurethane prepolymer; vacuum dehydrate 25 parts of diglycidyl tetrahydrophthalate at 80°C for 1-3 hours, cool down to 60°C, and then Add the polyurethane prepolymer, 12 parts of 1,4-buta...

Embodiment 3

[0038] The material of the outer sheath layer 7 is an environmentally friendly flame retardant material. The environmentally friendly flame retardant material consists of 65 parts of high density polyethylene, 22 parts of epoxy modified polyurethane, 5 parts of ethylene-acrylic acid magnesium ionomer, 10 parts of stearic acid, Composed of 2 parts of dilauryl thiodicarboxylate and 4 parts of polyethylene carbon black masterbatch;

[0039] The epoxy-modified polyurethane is obtained by the following method: put 35 parts of polyether polyol into the reaction kettle, heat to 120°C for reflux dehydration for 1 hour while stirring, then add 40 parts of toluene diisocyanate when the temperature is lowered to 50°C, slowly Raise the temperature to 80°C, stir and react for 4-6 hours to obtain a polyurethane prepolymer; vacuum dehydrate 15-25 parts of diglycidyl tetrahydrophthalate at 80°C for 1-3 hours, and cool down to 60°C , adding the polyurethane prepolymer, 9 parts of 1,4-butanedio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com