Phosphate oxidation antirust treatment solution and antirust treatment process of steel part

A technology of anti-rust treatment and phosphate, which is applied in the coating process of metal materials, etc., can solve the problem of corrosion resistance reduction, and achieve the effect of small surface roughness and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

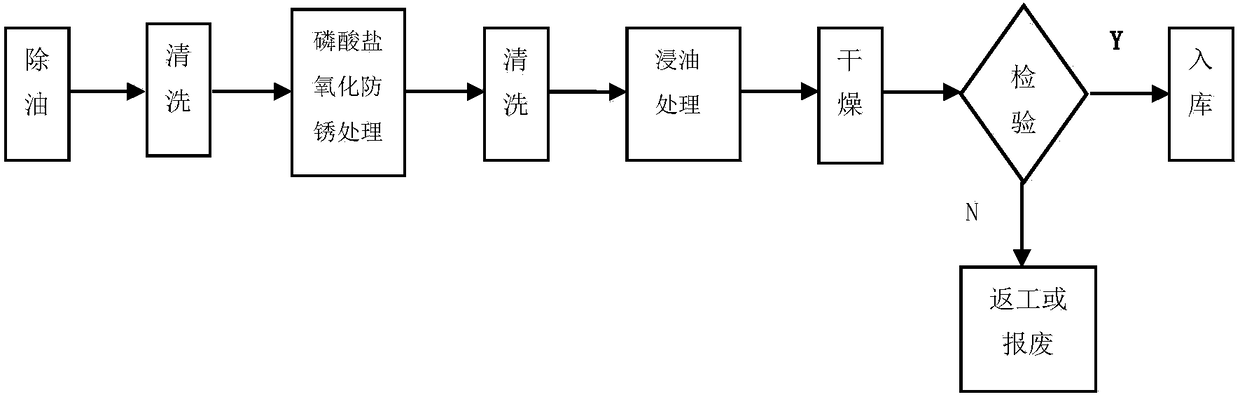

Method used

Image

Examples

Embodiment 1

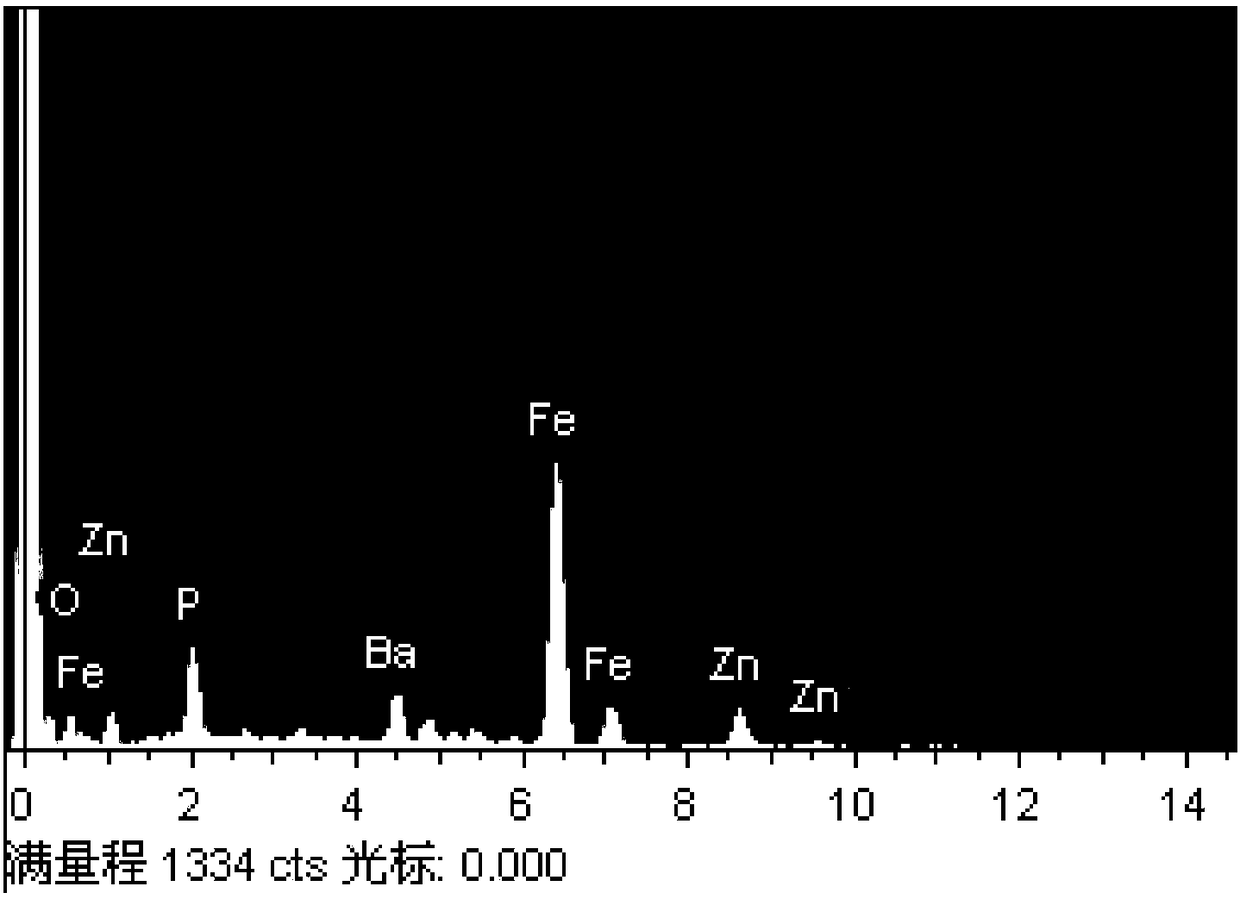

[0034] The formula and the content of each component of the iron and steel parts phosphate oxidation antirust treatment solution adopted in the present embodiment are respectively barium nitrate 35g / L, zinc nitrate 15g / L, zinc phosphate 10g / L; Treatment process Phosphate oxidation anti-rust treatment of steel parts. 12CrNi3A iron and steel parts are subjected to phosphate oxidation anti-rust treatment, wherein the temperature of the solution is 80°C and the time is 10 minutes.

[0035] After the treatment process described in the present invention, the iron and steel parts are subjected to phosphate oxidation and antirust treatment to form a phosphate oxidation and antirust film layer. After the phosphate oxidation and antirust treatment, the iron and steel parts are subjected to a neutral salt spray test, and after 28 hours After that, no rust phenomenon was found, that is, the neutral salt spray test of the phosphate oxidation antirust film layer obtained by the antirust tre...

Embodiment 2

[0037] The formula and the content of each component of the iron and steel parts phosphate oxidation antirust treatment solution adopted in the present embodiment are respectively barium nitrate 35g / L, zinc nitrate 15g / L, zinc phosphate 10g / L; Treatment process Phosphate oxidation anti-rust treatment of steel parts. Carburize the steel parts of 12CrNi3A first (the thickness of the carburized layer is 0.03 mm), and then carry out the phosphate oxidation antirust treatment, wherein the temperature of the solution is 73 °C. Time 3 minutes.

[0038] After the treatment process described in the present invention, the iron and steel parts after carburizing are subjected to phosphate oxidation and antirust treatment to form a phosphate oxidation and antirust film layer, and at the same time, the iron and steel parts are subjected to a neutral salt spray test after the phosphate oxidation and antirust treatment , after 24 hours, no rust phenomenon was found, that is, the neutral salt...

Embodiment 3

[0040]The formula and the content of each component of the iron and steel parts phosphate oxidation antirust treatment solution adopted in the present embodiment are respectively barium nitrate 35g / L, zinc nitrate 15g / L, zinc phosphate 10g / L; Treatment process Phosphate oxidation anti-rust treatment of steel parts. The steel parts of 12CrNi3A are first nitrided (the thickness of the nitriding layer is 0.06 mm), and then phosphate oxidation antirust treatment is carried out, and the temperature of the solution is 73 ° C. Time 3 minutes.

[0041] After the treatment process described in the present invention, the iron and steel parts after nitriding are subjected to phosphate oxidation and antirust treatment to form a phosphate oxidation and antirust film layer, and at the same time, the iron and steel parts are subjected to a neutral salt spray test after the phosphate oxidation and antirust treatment , after 24 hours, no rust phenomenon was found, that is, the neutral salt sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com