A preparation method of high-strength degradable nano-medicine titanium-magnesium-silicon composite material

A silicon composite material and composite material technology, applied in the field of medical implants, can solve problems such as poor affinity and degradability, non-healing, and ingrown bone tissue, and achieve good biocompatibility and good fatigue resistance Effects of corrosion resistance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: Preparation method of a high-strength nano-medicine titanium-magnesium-silicon composite material

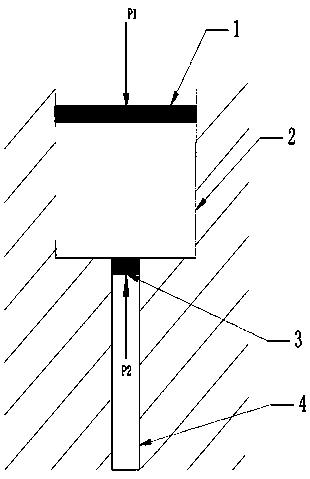

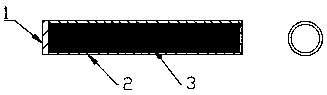

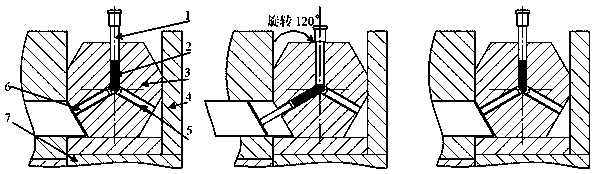

[0033]Ti powder, Mg particles (purity 99.6%), Si particles (purity 99.9%), V particles, Ag particles and TiC-SiC-VC-ZrC whisker particles in a molar ratio of 50:30:15:3: 1.5:0.5 uniformly mixed and prepared, bonded with isopropanol, then extruded on a press through a press die, and dried at room temperature for 5 minutes, so that the isopropanol evaporates and the adhesion between the particles disappears, Finally, a rod-shaped sample of D10mm×68mm was formed; the rod-shaped sample was put into the sheath, rotated repeatedly through the trident-shaped channel, and extruded 6 times, resulting in severe plastic deformation to obtain a titanium-magnesium-silicon composite material with nano-grain structure. The rod-shaped nanomaterials produced by the mold channel were washed and ultrasonically cleaned with distilled warm water, then washed with distilled warm wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com