Laser crystal plasma modified etching assisted polishing processing method

A plasma and laser crystal technology, applied in the field of high-precision, low-damage, high-efficiency laser crystal materials, and ultra-smooth surface processing, can solve the problems of affecting material removal rate, grinding, polishing difficulties, slow response speed, etc., to avoid The effect of low rate correction process, improvement of processing efficiency, and increase of processing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

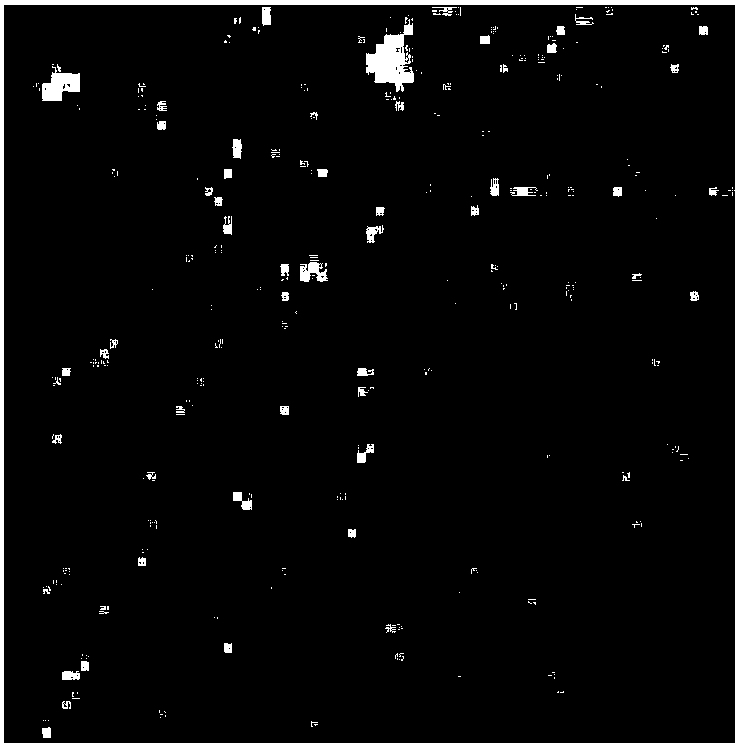

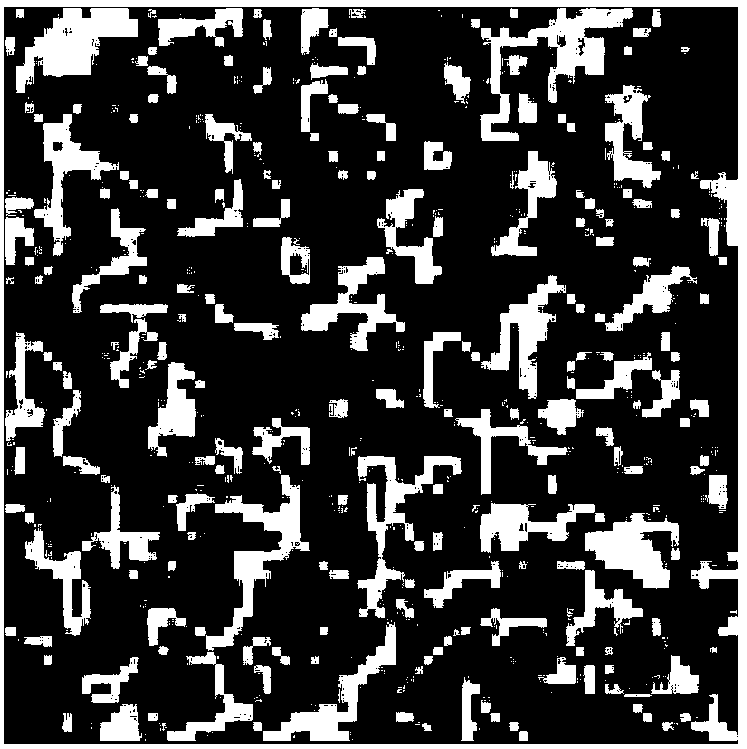

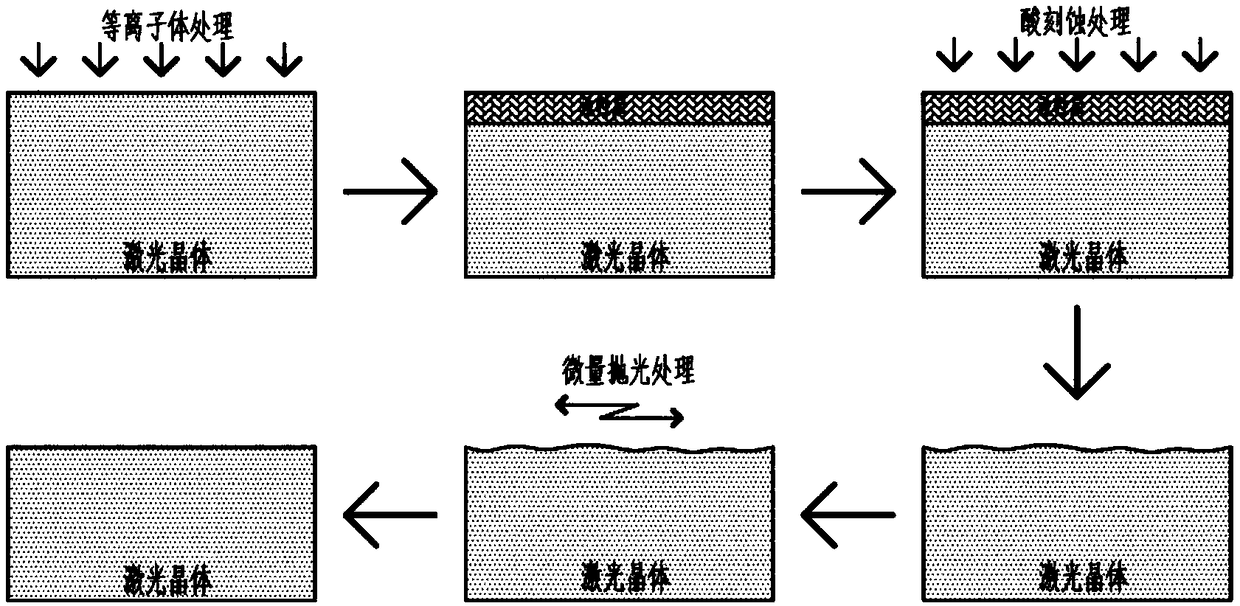

[0041]The invention takes the sesquioxide laser crystal as an example, adopts the plasma modified etching-assisted polishing method, and proposes a high-efficiency, high-precision, and non-damaging processing method for the sesquioxide laser crystal. The present invention will be described in further detail below according to the accompanying drawings and examples. The present invention adopts sub-aperture etching processing, polishing system and in-situ measurement system to realize crystal surface modification processing, and the specific implementation steps are as follows:

[0042] ⑴Cut the sesquioxide lutetium oxide crystal blank, and perform pretreatment on the surface such as rough grinding, fine grinding and / or mechanical polishing, use W7~W10 silicon carbide for rough grinding, grinding time 20~40min, use for fine grinding Alumina of W1~W3, the grinding time is 60~90min to obtain lutetium oxide crystal rough material;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com