Graphene modified cyanate resin and preparation method thereof

A cyanate ester resin and graphene modification technology, which is applied in the field of resin modification, can solve problems such as the negative impact of the adhesive system, graphene agglomeration and phase separation, and the impact on material properties, so as to improve performance, improve interface bonding, The effect of improving interface binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] formula:

[0039] Bisphenol A type cyanate prepolymer (pale yellow viscous liquid) 100 parts by weight

[0040] Graphene 5 parts by weight

[0041] KBM-403 silane coupling agent 1 weight

[0042] Preparation Process:

[0043] 1. Weigh 100 parts of cyanate resin into a three-necked flask, and heat it at (70-80)°C to make it a flowing liquid.

[0044] 2. Control the speed of the mixer (200-250) r / min, add 1 part of heavy coupling agent to the three-necked flask, and stir evenly.

[0045] 3. Add 0.5 parts by weight of graphene, stir evenly and continue to stir for 60 minutes to obtain cyanate resin A.

[0046] 4. Pour the remaining 4.5 parts of heavy graphene into the non-interventional gravity disperser cup, add cyanate resin A, and tighten the cup lid.

[0047] 5. Start the non-interventional gravity disperser, set the revolution speed to 1500r / min, the rotation speed to 3000r / min, and control the dispersion time to 15min to obtain graphene-modified cyanate resin.

...

Embodiment 2

[0052] Proportion:

[0053] Dicyclopentadiene bisphenol cyanate (brown liquid) 100 parts by weight

[0054] Graphene 10 parts by weight

[0055] KH550 silane coupling agent 2 parts by weight

[0056] Except that the type and proportion of cyanate resin are different, and the graphene added in the first part is 1 part, other preparation processes are the same as in Example 1.

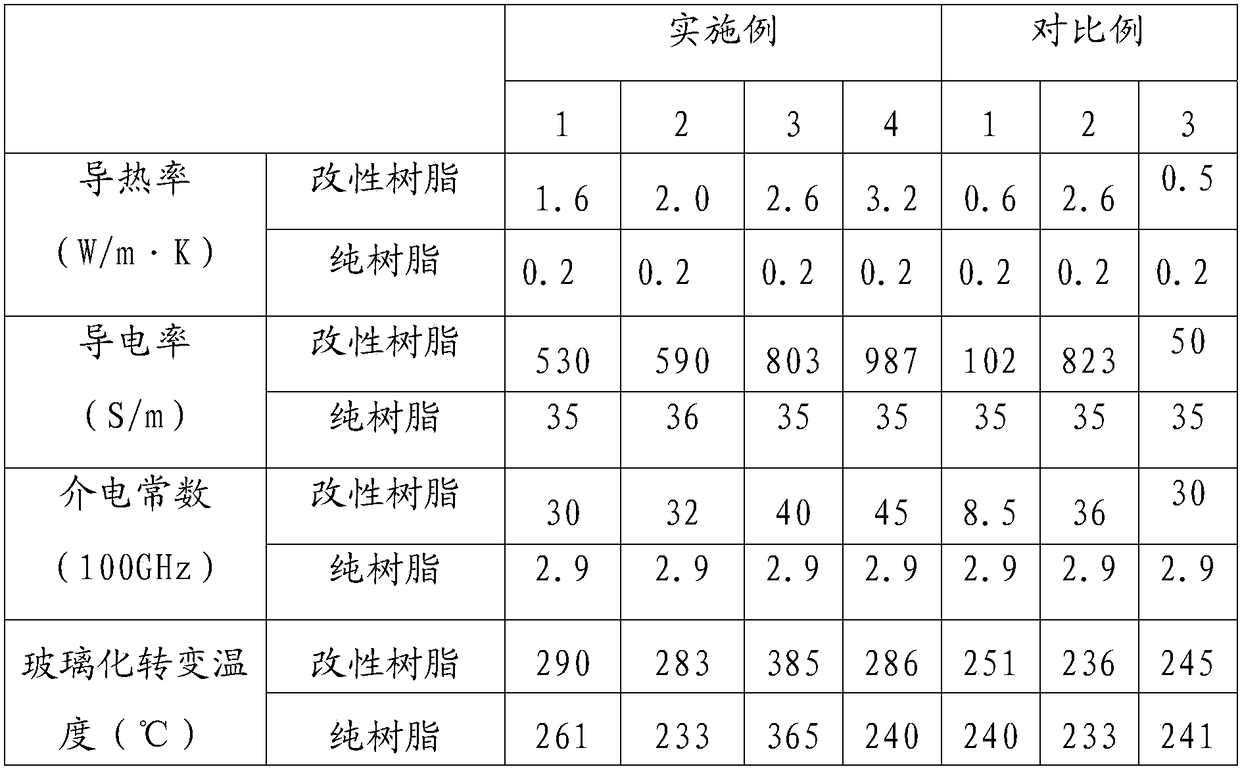

[0057] The thermal conductivity, electrical conductivity, dielectric properties and glass transition temperature of graphene modified cyanate resin cured products are shown in Table 1.

Embodiment 3

[0059] Proportion:

[0060] Phenolic polyfunctional cyanate (brown liquid) 100 parts by weight

[0061] Graphene 15 parts by weight

[0062] KH560 silane coupling agent 2 parts by weight

[0063] Except that the type and proportion of cyanate resin are different, other preparation processes are the same as in Example 2.

[0064] The thermal conductivity, electrical conductivity, dielectric properties and glass transition temperature of graphene modified cyanate resin cured products are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com