Anti-yellowing thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and polyurethane elastomer technology, which is applied in the field of rapid prototyping and yellowing-resistant thermoplastic polyurethane elastomer and its preparation, can solve problems such as affecting the appearance and service life of products, polluting the environment of production personnel, and accelerating product aging, and achieves excellent results. Anti-yellowing performance, shortening injection cycle, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

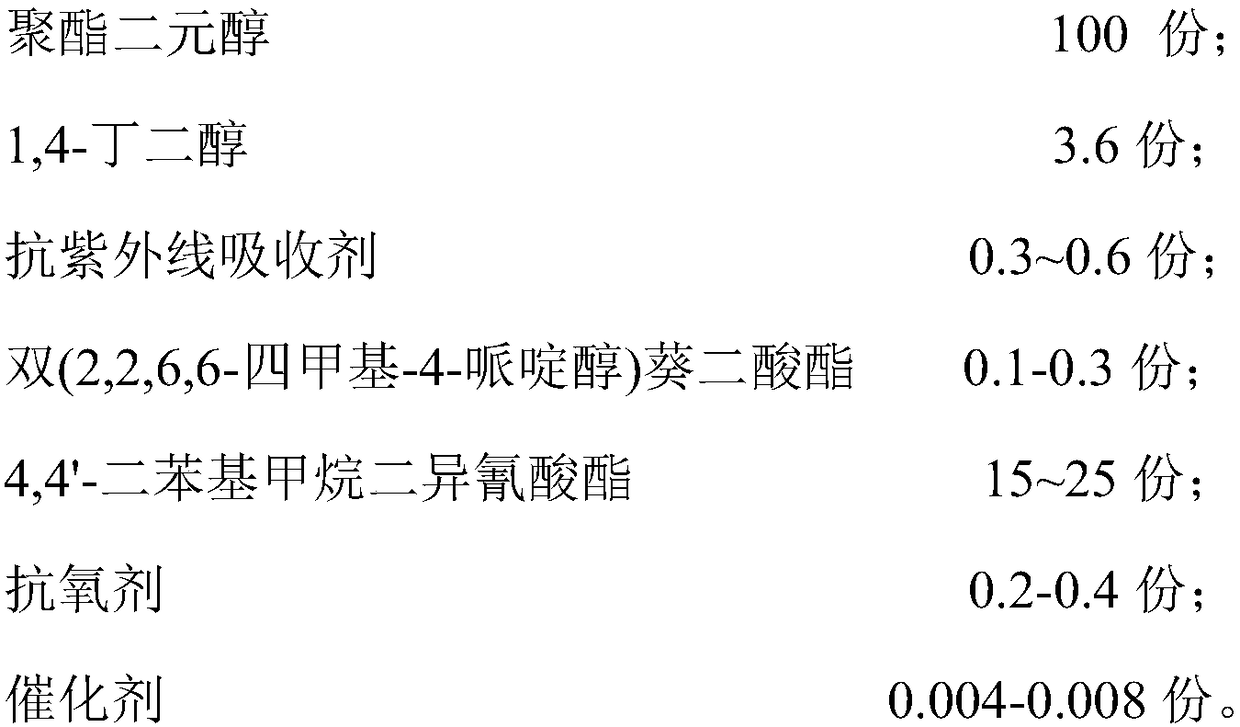

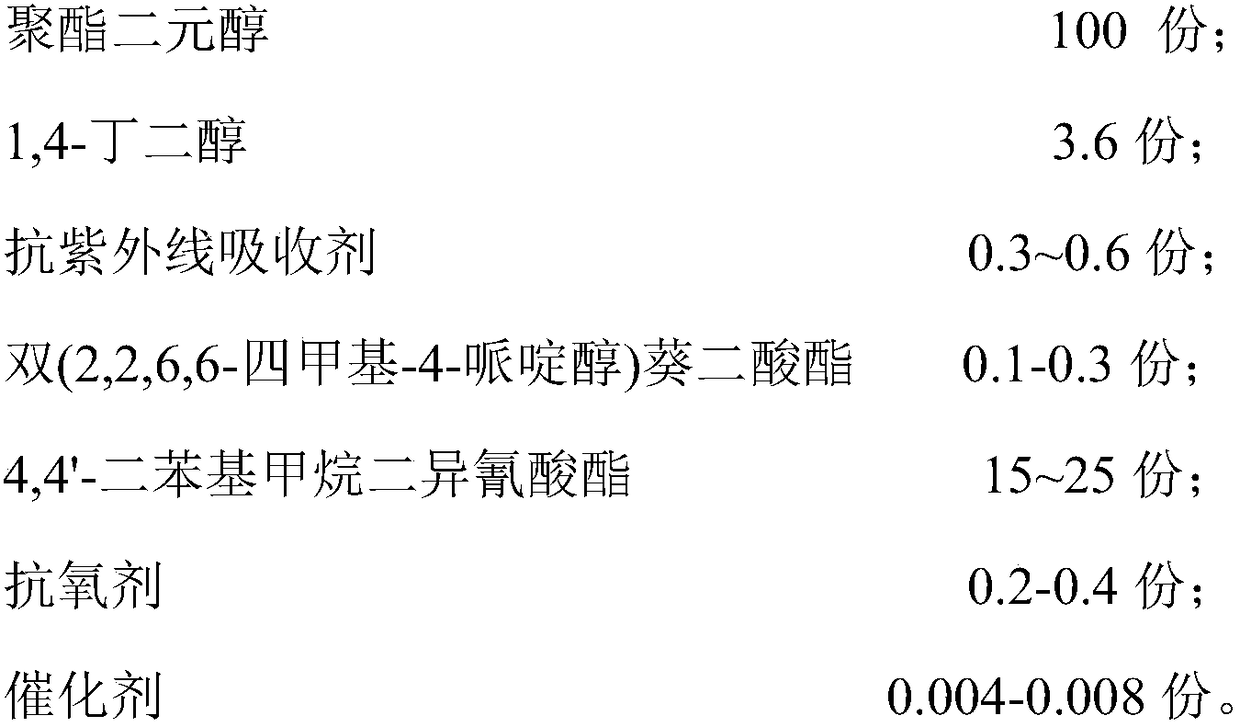

[0021] A preparation method of an anti-yellowing thermoplastic polyurethane elastomer, comprising the following processes:

[0022] (1) Preparation of the pre-mixture: Add 1kg of polyadipate-1,4-butylene glycol ester diol, 36g of 1,4-butanediol, and ultraviolet absorber into a 2000mL three-necked flask with a stirrer and a thermometer 2-(2'-Hydroxy-3',5'-di-t-pentylphenyl)benzotriazole 5g, bis(2,2,6,6-tetramethyl-4-piperidinol) sebacic acid 2.5g of ester, 2g of antioxidant 1010 and 2g of antioxidant 168 were gradually heated up to 90°C for 30 minutes under vacuum dehydration while stirring to obtain a premixture. The molecular weight of the polyadipate-1,4-butylene glycol ester diol is 3500.

[0023] (2) Rapid prototyping process: under the condition of rapid stirring, add 181 g of measured and pre-melted 4,4'-diphenylmethane diisocyanate and 1 drop of catalyst stannous octoate to the pre-mixture obtained above to make Fully stir the reaction, the reaction temperature is 75 ...

Embodiment 2

[0025] A preparation method of an anti-yellowing thermoplastic polyurethane elastomer, comprising the following processes:

[0026] (1) Preparation of the pre-mixture: Add 1 kg of polyethylene adipate-1,4-butanediol ester diol, 36 g of 1,4-butanediol, UV absorber 2-(2'-hydroxy-3',5'-dipentylphenyl)benzotriazole 5g, bis(2,2,6,6-tetramethyl-4-piperidinol) 2.5g of sebacate, 2g of antioxidant 1010 and 2g of antioxidant 168 were gradually heated up to 90°C for 30 minutes under vacuum dehydration while stirring to obtain a premixture. The polyethylene adipate-1,4-butylene glycol ester diol molecular weight is 3500;

[0027] (2) Rapid prototyping process: under the condition of rapid stirring, add 181 g of measured and pre-melted 4,4'-diphenylmethane diisocyanate and 1 drop of catalyst stannous octoate to the pre-mixture obtained above to make Fully stir the reaction, the reaction temperature is 75 ~ 85 ℃, depending on the high viscosity, it can be poured out in about 2 minutes. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com