Method for producing ethanol, soap and feed from kitchen waste

A technology of food waste and ethanol, which is applied in the field of resource treatment of food waste, can solve the problems that pathogens and thermophilic microorganisms cannot be killed, the recycling rate of resources is only 20%, and the acceleration of feed corruption and oxidation can be achieved. Obvious anti-oxidation effect, improve anti-stress and immunity, and prevent feed mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

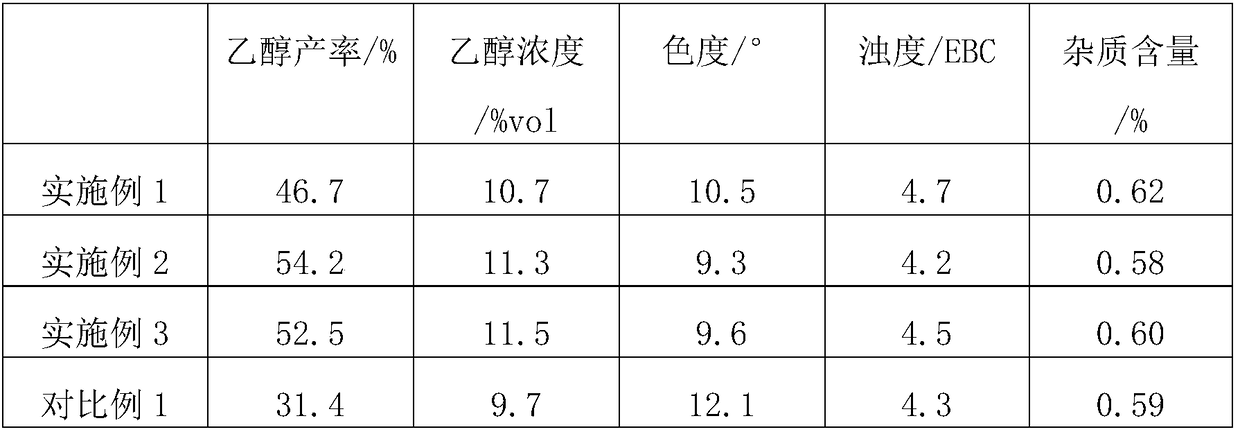

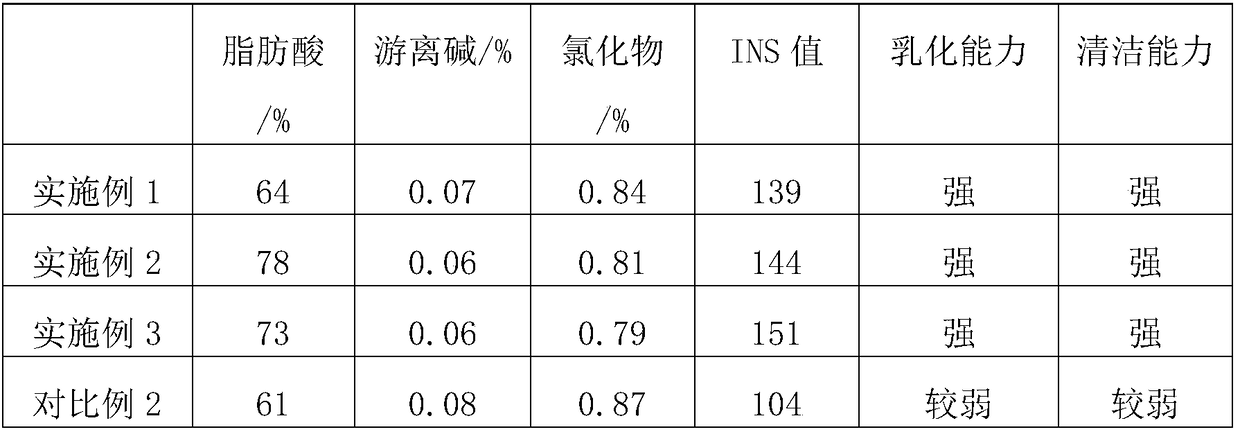

Embodiment 1

[0027] Step 1: filter kitchen waste to obtain oil-water mixture and solid kitchen waste;

[0028] Step 2: Mix α-1,4-glucohydrolase, α-amylase and β-amylase according to the weight ratio of 1:(0.5-0.7):(0.3-0.5) to prepare a compound enzyme, and grind the kitchen solid Garbage until the fineness is 60-100 mesh, and add 20-30wt% corn starch, 0.6-1.8wt% compound enzyme and 50-60wt% water to it, stir evenly, and saccharify at 55-70°C for 5-7h Afterwards, make fermentation substrate;

[0029] Step 3: At 30-35°C, mix 0.3-0.5wt% of Candida into the fermentation substrate for fermentation, perform aerobic fermentation on the 1st-2nd day, and perform anaerobic fermentation on the 2nd-6th day, The total fermentation period is 6-8 days, and the ethanol is obtained after distillation and rectification;

[0030] Step 4: Separate the grease in the oil-water mixture, add 6wt% activated clay to it for adsorption and decolorization, then add NaOH solution until the pH is 7.5-7.8, saponify fo...

Embodiment 2

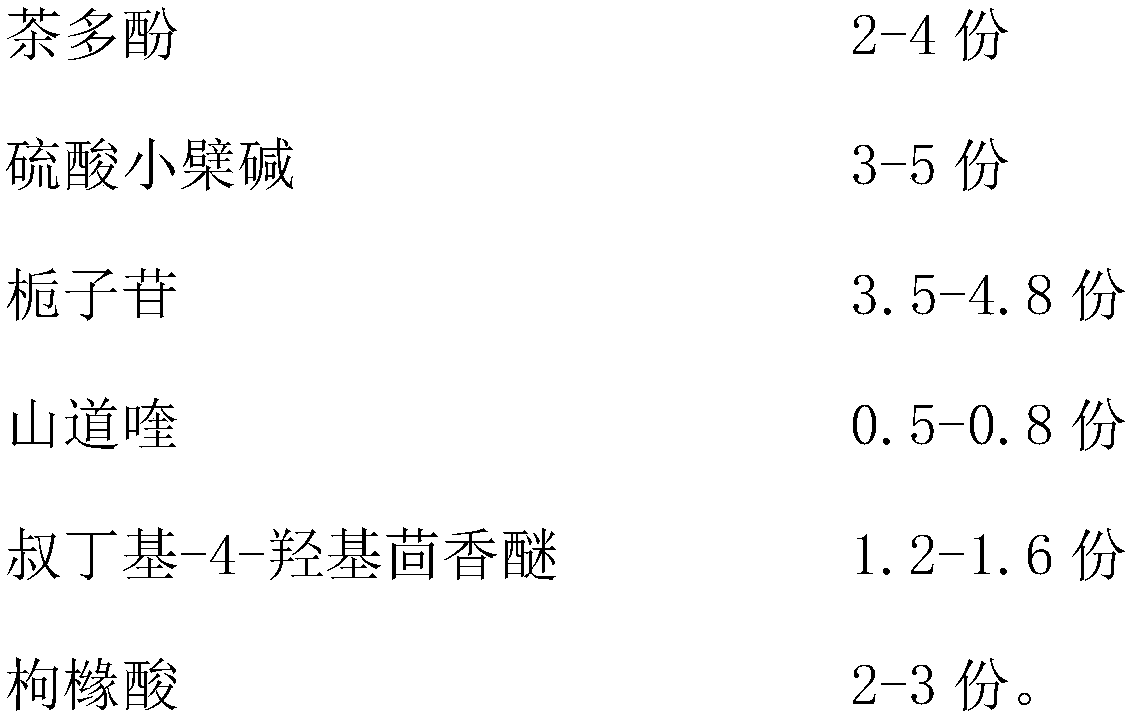

[0035] Operation example 1, wherein, the weight ratio of the components of the complex enzyme in step 2 is 1:0.6:0.4, the fineness of grinding: 80 mesh, the weight percentages of the raw materials of the fermentation substrate: 25wt%, 1.2wt%, 55wt%, saccharification: 63°C, 6h; fermentation in step 3: 33°C, 7 days, yeast: 0.4wt%, Torulopsis globosa; decolorization in step 4: activated alumina adsorption method, PH: 7.6, saponification: 2.5h, NaCl : 12.5wt%; temperature in step five: 45°C, methyl ethyl ketone peroxide: 1.5wt%, associative polyurethane: 17.5wt%, settling time: 30h; parts by weight of each component of feed additive in step six: 3 parts, 4 parts, 4.2 parts, 0.7 parts, 1.4 parts, 2.5 parts; beer tank in step 7: 30wt%, feed additive: 3wt%, ultraviolet light: 225μW / cm 2 , 6.5min.

Embodiment 3

[0037] Operation example 1, wherein, the weight ratio of the components of the complex enzyme in step 2 is 1:0.7:0.5, the fineness of grinding: 100 mesh, the weight percentages of the raw materials of the fermentation substrate: 30wt%, 1.8wt%, 60wt%, saccharification: 70°C, 7h; fermentation in step 3: 35°C, 8 days, yeast: 0.5wt%, Hansenula and Kluyveromyces; decolorization in step 4: ion exchange resin method, PH: 7.8 , saponification: 3h, NaCl: 15wt%; temperature in step five: 50°C, methyl ethyl ketone peroxide: 2wt%, associative polyurethane: 20wt%, precipitation time: 36h; parts by weight of each component of the feed additive in step six: 4 parts, 5 parts, 4.8 parts, 0.8 parts, 1.6 parts, 3 parts; beer tank in step 7: 35wt%, feed additive: 4wt%, ultraviolet light: 250μW / cm 2 , 8min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com