A side-by-side composite fiber

A composite fiber and fiber technology, which is applied in fiber processing, filament/thread forming, conjugated synthetic polymer rayon, etc., can solve the problems of high elongation of elastic elastic fibers, affecting appearance, and limiting the scope of use. Achieve the effect of improving the elastic recovery rate, good elasticity, and reducing the cost of fiber raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

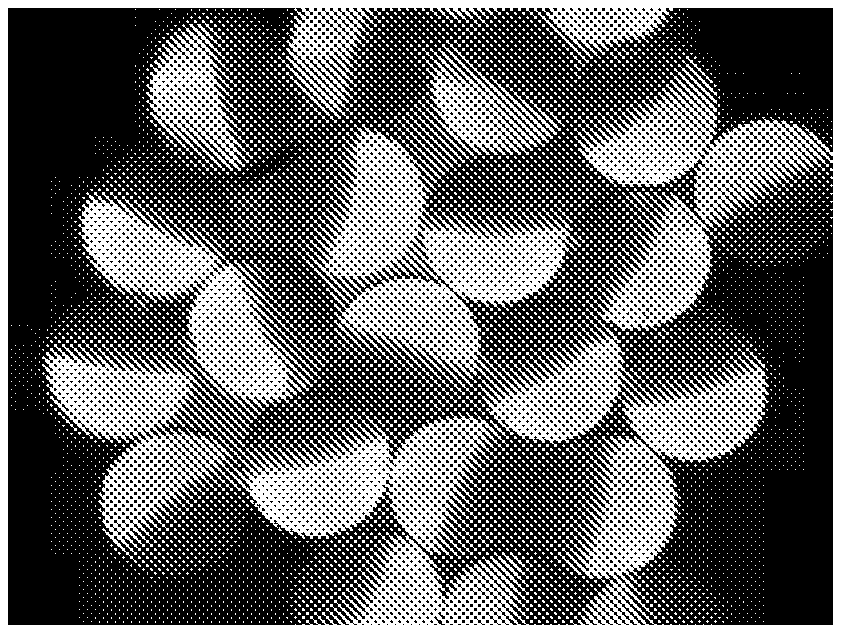

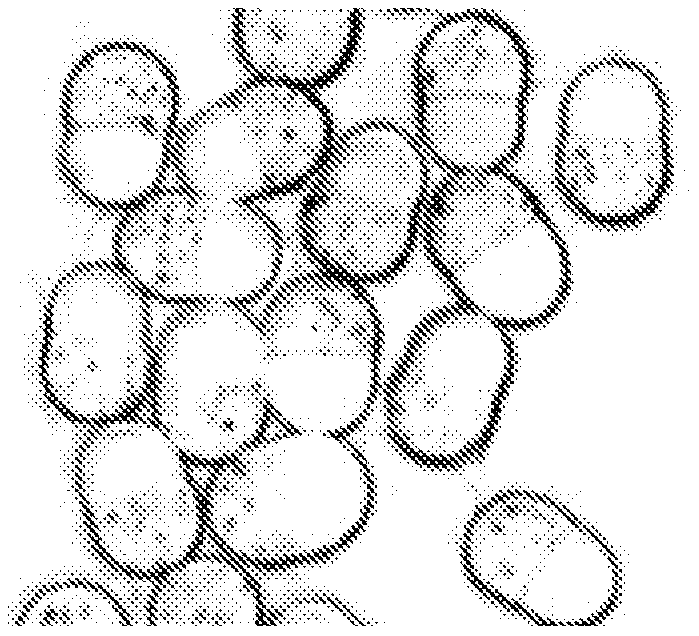

Image

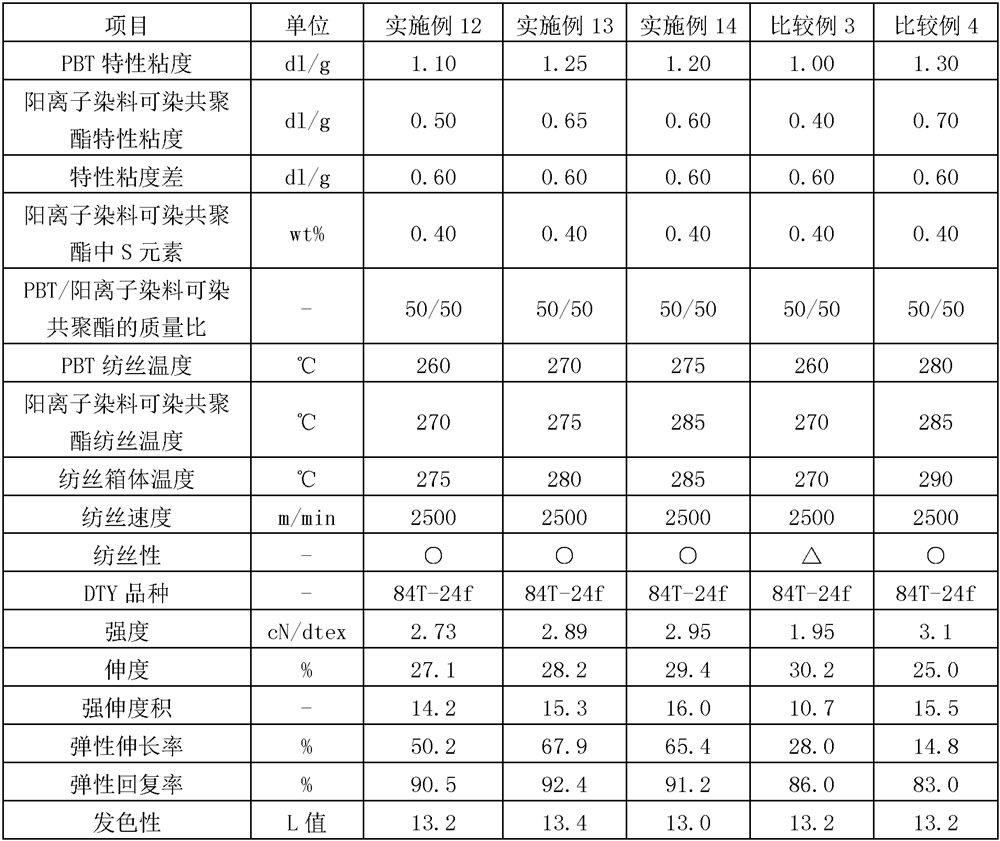

Examples

Embodiment 1

[0051] The two-component elastic fiber is prepared by the melting method, and polybutylene terephthalate with an intrinsic viscosity of 1.31dl / g and polyethylene terephthalate with an intrinsic viscosity of 0.51dl / g are selected for composite spinning. Their intrinsic viscosity difference is 0.80dl / g. Dry them separately so that the water content is less than 100ppm, and then put the dried polybutylene terephthalate and polyethylene terephthalate into No. 1 / No. 2 spinning boxes at a weight ratio of 50:50. Set the spinning temperature, the screw temperature of the No. 1 extruder is 265°C; the screw temperature of the No. 2 spinning machine is 285°C; the temperature of the spinning box is 270°C. Use side-by-side spinnerets to spin out, set the winding speed to 2500m / min, and control the raw silk variety to 300dtex / 48F.

[0052] False-twisting disc-false-twisting processing is performed on the wound pre-oriented yarn, the temperature of the hot box is 190°C, the false-twisting m...

Embodiment 2

[0055] Adopt the polymer weight ratio identical with embodiment 1, spinning temperature, spinning speed, precursor kind, processing method, processing temperature, processing ratio, processing speed, but change the intrinsic viscosity difference of two kinds of polymers, select intrinsic viscosity Polybutylene terephthalate with an intrinsic viscosity of 1.50dl / g and polyethylene terephthalate with an intrinsic viscosity of 0.45dl / g were used for composite spinning, and their intrinsic viscosity difference was 1.05dl / g. See Table 1 for specific values.

Embodiment 3

[0057] Adopt the polymer weight ratio identical with embodiment 1, spinning temperature, spinning speed, precursor kind, processing method, processing temperature, processing ratio, processing speed, but change the intrinsic viscosity difference of two kinds of polymers, select intrinsic viscosity Polybutylene terephthalate with an intrinsic viscosity of 1.00dl / g and polyethylene terephthalate with an intrinsic viscosity of 0.60dl / g are used for composite spinning, and their intrinsic viscosity difference is 0.40dl / g. See Table 1 for specific values.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com