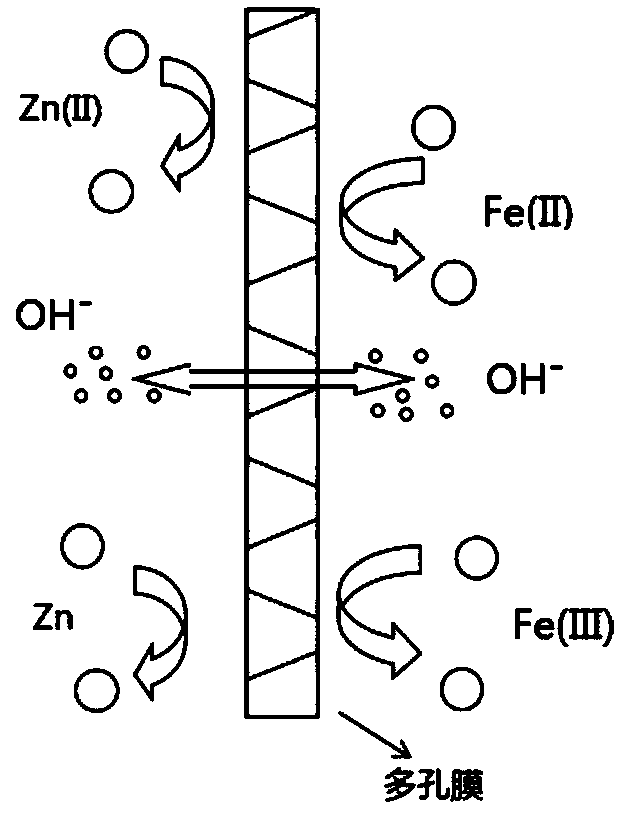

Application of porous membrane in alkaline zinc-iron flow battery

A liquid flow battery and porous membrane technology, applied in the direction of fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as instability and hindering technology development, to overcome poor stability, expand types and use range, and controllable thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

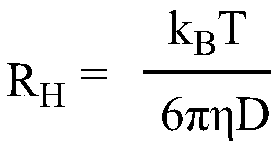

[0031] Dissolve 7.5 grams of polyacrylonitrile in 30ml of DMSO and 10ml of THF, stir for 5 hours, spread the polymer solution on a glass plate with a thickness of 250μm, then quickly immerse in 5L of water, solidify, and form a pore size of 50nm with a porosity of 55 % porous membrane.

[0032] The prepared porous membrane was treated in 10 wt.% sodium hydroxide aqueous solution for 55 minutes, and the treatment temperature was 55°C. Then the membrane was cleaned with deionized water, soaked in ethanol for 2 hours, and the water in it was replaced.

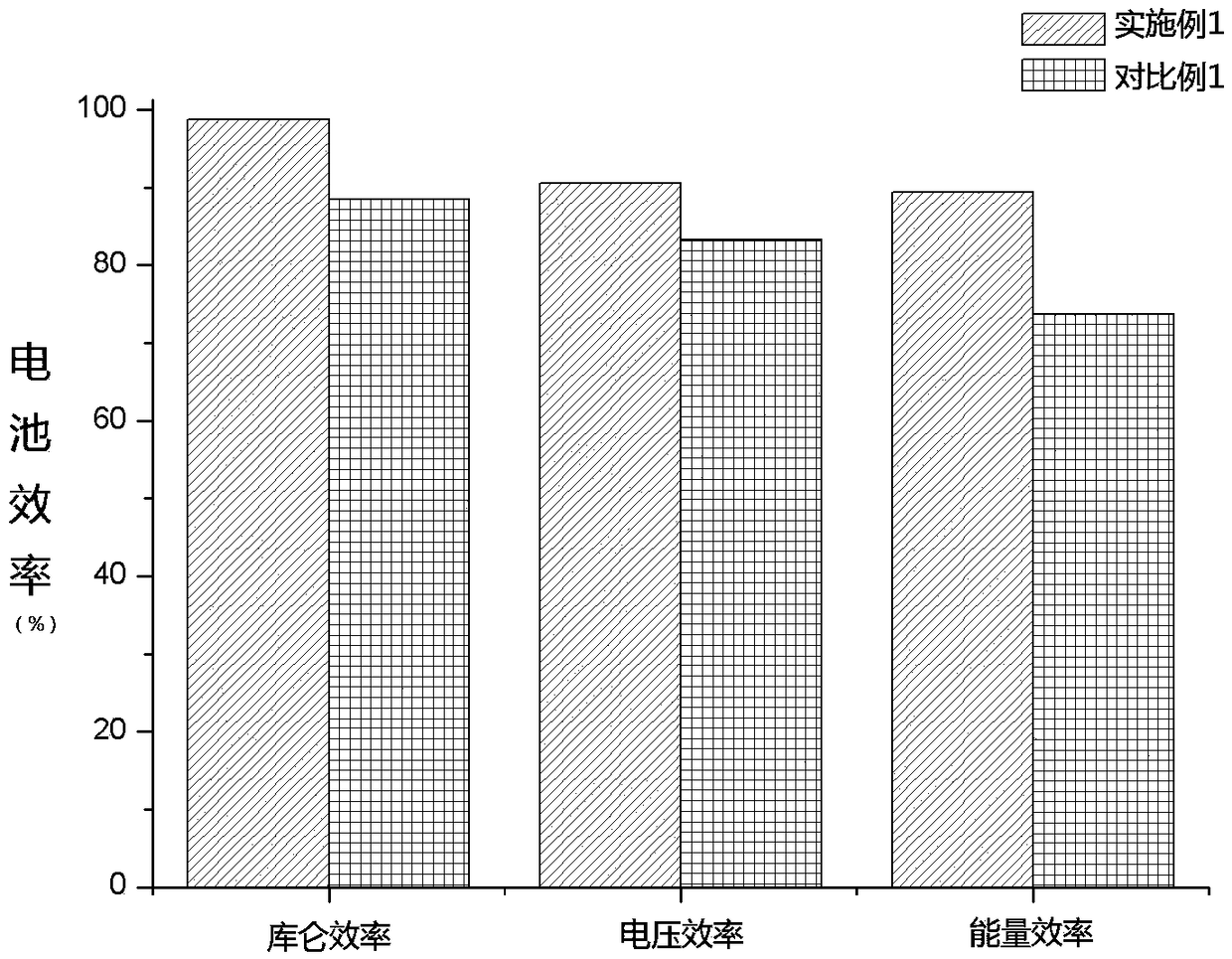

[0033] The prepared porous membrane is used to assemble the alkaline system zinc-iron flow battery, in which the catalytic layer is activated carbon felt, the bipolar plate is graphite plate, and the effective area of the membrane is 48cm 2 , with a current density of 80mA cm -2 , the zincate ion concentration in the electrolyte is 0.5mol L -1 , the concentration of ferrocyanogen cyanide ion is 1mol L -1 . The coulombic eff...

Embodiment 2

[0041] Same as Example 1, the polymer is replaced by polysulfone, and other conditions remain unchanged.

Embodiment 3

[0043] Same as Example 1, the polymer is replaced by polyimide, the solvent is replaced by NMP, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com