Fluorinated modified sulfonated polyarylether and preparation method and application thereof

A sulfonated polyarylene ether and modification technology, which is applied in the field of fluorinated modified sulfonated polyarylene ether and its preparation, can solve the problems of sulfonated polymer fluorination, change of material adhesion, complex synthesis route, etc. Achieve the effects of improving chemical stability and proton conductivity, short fluorination time, and low raw material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

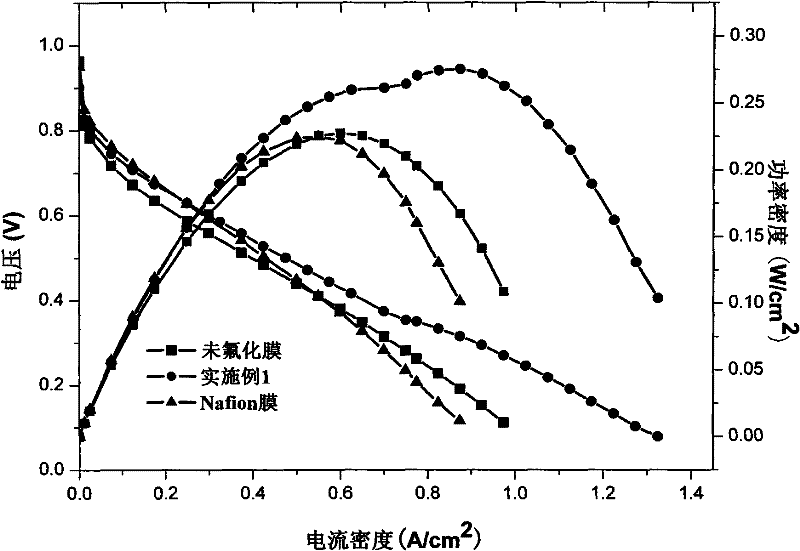

Embodiment 1

[0043] Dissolve 5g of sulfonated polyarylene ether in 100ml of dimethyl sulfoxide, pour it on a glass plate; let it stand at 80°C for 24h, cool to room temperature after film formation, and remove the film.

[0044]Dry the sulfonated polyarylether film in a vacuum oven at 100°C for 12 hours;

[0045] Place the dried sulfonated polyarylether film in a metal-sealed horizontal reaction kettle, turn on the built-in fan of the reaction kettle to form a gas circulation in the sealed kettle, and introduce nitrogen to replace the gas in the kettle for several times, and then Heat up to 60°C;

[0046] Open the nitrogen valve to adjust the pressure of nitrogen in the kettle, and then open the fluorine valve to feed the fluorine gas of the set pressure, so that the concentration of fluorine in the mixed gas is 4%, and the gas pressure in the kettle is 0.03MPa; after 2 hours of reaction, The reactor was purged 5-10 times with nitrogen.

[0047] The reacted membrane is soaked in 1 mol / L ...

Embodiment 2

[0049] Grind the sulfonated polyarylether into powder, and dry it in a vacuum oven at 100°C for 12 hours;

[0050] The dried sulfonated polyarylether powder is placed in a metal-sealed horizontal reactor, and the built-in fan of the reactor is turned on to form a circulating flow of gas in the sealed reactor, and nitrogen gas is introduced to replace the gas in the reactor for many times, and then the temperature is raised. to 60°C;

[0051] Open the nitrogen valve to adjust the pressure of nitrogen in the kettle, and then open the fluorine valve to feed the fluorine gas of the set pressure, so that the concentration of fluorine in the mixed gas is 4%, and the gas pressure in the kettle is 0.03MPa; after 2 hours of reaction, The reactor was purged 5-10 times with nitrogen.

[0052] Dissolve 5 g of the above-mentioned powder in 100 ml of dimethyl sulfoxide, pour it on a glass plate; let it stand at 80°C for 24 hours, cool to room temperature after film formation, and remove th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com