Preparation method of veneer decorative paper capable of purifying formaldehyde, and veneer decorative paper

A decorative paper and decorative surface technology, applied in the direction of surface covering paper, paper, papermaking, etc., can solve the problems of general performance, indoor formaldehyde concentration exceeding the standard, complex process, etc., and achieve improved film-forming properties, cohesive force, and good hydrolysis Stability, the effect of reducing formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

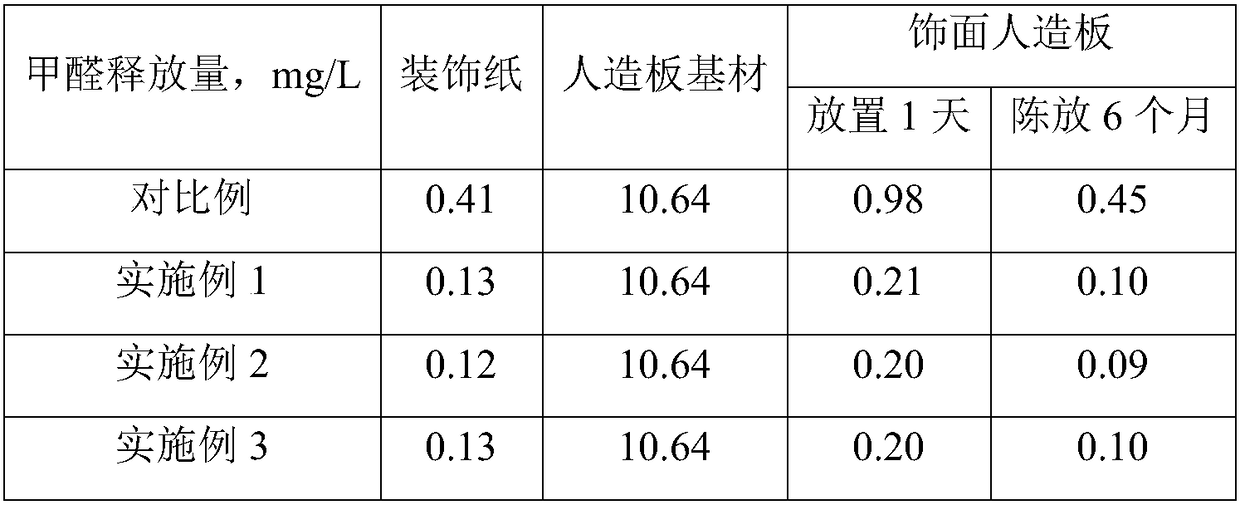

Examples

Embodiment 1

[0037] The preparation method of the facing decoration paper capable of purifying formaldehyde of the present embodiment comprises the following steps:

[0038]1) Glue adjustment: Take 100 parts by weight of urea-formaldehyde resin, add 3.0 parts by weight of phosphate-type amphoteric starch and 1.8 parts by weight of water-soluble chitosan in a water bath at 60°C under continuous stirring conditions, stir evenly, and then cool down to 40°C. Add 0.3 parts by weight of ethylenediamine, 0.5 parts by weight of borax, 0.3 parts by weight of ammonium sulfate and 0.3 parts by weight of penetrating agent sodium dodecylbenzene sulfonate, stir well to obtain impregnated glue;

[0039] 2) Dipping: take a quantitative value of 70g / m 2 The decorative base paper is impregnated with the impregnated glue obtained in step 1). The impregnated time is 100s. Not more than 10%, the amount of glue is 15g / m 2 ;

[0040] The mixed atmosphere refers to a mixed gas of dry air and ammonia, wherein t...

Embodiment 2

[0045] The preparation method of the facing decoration paper capable of purifying formaldehyde of the present embodiment comprises the following steps:

[0046] 1) Glue adjustment: Take 100 parts by weight of urea-formaldehyde resin, add 3.2 parts by weight of powdered phosphate-type amphoteric starch and 1.6 parts by weight of water-soluble chitosan under the condition of a water bath at 65°C, stir evenly, cool down to 45°C, and add 0.2 parts by weight The ethylenediamine of part, the borax of 0.4 weight part, the ammonium sulfate of 0.4 weight part and the penetrating agent sodium dodecylbenzene sulfonate of 0.4 weight part get dipping glue after stirring;

[0047] 2) Dipping: take a quantitative value of 70g / m 2 The decorative base paper is impregnated with the impregnated glue obtained in step 1). The impregnated time is 110s. More than 10%, the amount of glue is 20g / m 2 ;

[0048] The mixed atmosphere refers to a mixed gas of dry air and ammonia, wherein the volume fra...

Embodiment 3

[0053] The preparation method of the facing decoration paper capable of purifying formaldehyde of the present embodiment comprises the following steps:

[0054] 1) Glue adjustment: Take 100 parts by weight of urea-formaldehyde resin, add 3.5 parts by weight of powdered phosphate-type amphoteric starch and 1.2 parts by weight of water-soluble chitosan under the condition of a water bath at 65°C, stir evenly, cool down to 45°C, and add 0.4 parts by weight The ethylenediamine of part, the borax of 0.6 weight part, the ammonium sulfate of 0.2 weight part and the penetrating agent sodium dodecylbenzene sulfonate of 0.2 weight part get dipping glue after stirring;

[0055] 2) Dipping: take a quantitative value of 70g / m 2 The decorative base paper is impregnated with the impregnated glue obtained in step 1). The impregnated time is 120s. More than 10%, glue amount is 15g / m 2 ;

[0056] The mixed atmosphere refers to a mixed gas of dry air and ammonia, wherein the volume fraction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com