Insulating mortar for buildings and preparation method thereof

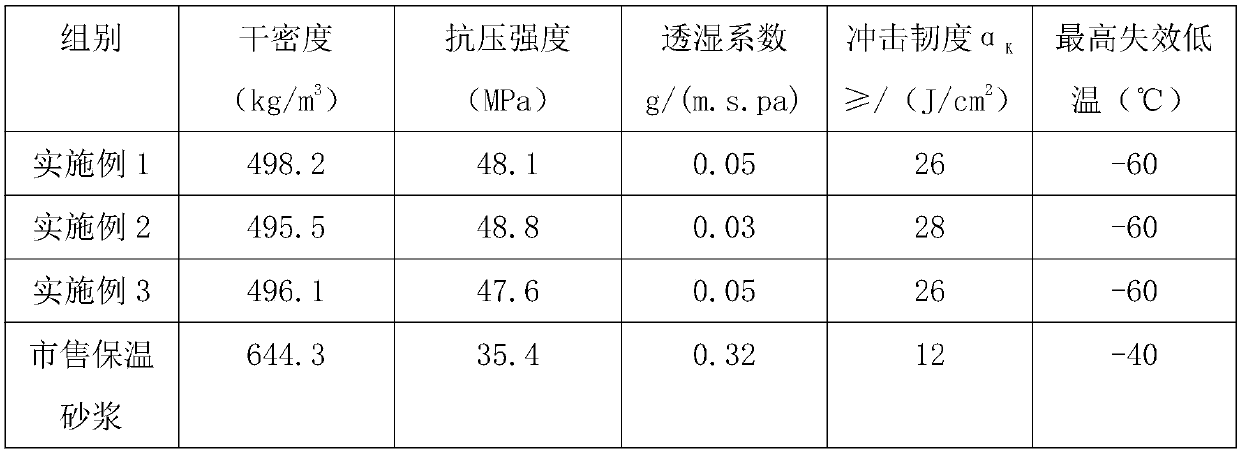

A technology for thermal insulation mortar and construction, applied in the field of thermal insulation mortar for construction and its preparation, can solve the problems affecting the reliability, durability and safety of building structures, poor impact resistance, low mechanical strength, etc. Freeze resistance, high compressive strength, excellent waterproof and frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of thermal insulation mortar for construction, the following raw materials are prepared: 100kg of carbide slag, 60kg of boron mud, 25kg of modified shale pottery sand, 10kg of zuoyun clay, 8kg of sepiolite fiber, 3kg of microcline powder, 3kg of analcite powder, Calcium nitrate 1kg, polydimethylsiloxane 0.4kg, dimethyl sulfoxide 0.3kg, woody sodium carbonate 0.8kg, dehydrated acetic acid 0.6kg, polyacrylate copolymer emulsion 4kg, advanced fatty acid waterproofing agent 1kg, antifreeze 1kg (two mixtures of calcium chloride and sodium acetate, the mass ratio is 1:1), barium chloride coagulation regulator 1kg and sodium azobisisobutyronitrile air-entraining agent 1kg;

[0024] Preparation of modified shale pottery sand: Take 25kg of raw material shale pottery sand and put it in a calciner, calcinate at 680°C for 1.5h, take out the ground powder after natural cooling, pass through a 60-mesh sieve, and then add 1.5kg of lignin and 75kg of deionized water were stirred...

Embodiment 2

[0029] A kind of thermal insulation mortar for construction, the following raw materials are prepared: 110kg of carbide slag, 70kg of boron mud, 30kg of modified shale pottery sand, 11kg of zuoyun clay, 10kg of sepiolite fiber, 4kg of microcline powder, 4kg of analcite powder, Calcium nitrate 1.5kg, polydimethylsiloxane 0.5kg, dimethyl sulfoxide 0.4kg, wood sodium carbonate 1kg, dehydrated acetic acid 0.8kg, polyacrylate copolymer emulsion 5kg, inorganic aluminum salt waterproofing agent 1.5kg, di Methyl sulfoxide antifreeze 1.5kg, borax coagulation regulator 2kg and azodicarbonamide air-entraining agent 3kg;

[0030]Preparation of modified shale pottery sand: Take 30kg of raw shale pottery sand and place it in a calciner, calcinate at 700°C for 2h, take out the ground powder after natural cooling, pass through a 70-mesh sieve, and then add 2.1kg of wood Su and 120kg of deionized water were stirred evenly at 80°C, soaked for 9 hours, and then taken out by high-speed centrifuga...

Embodiment 3

[0035] A kind of thermal insulation mortar for construction, the following raw materials are prepared: 120kg of calcium carbide slag, 80kg of boron mud, 35kg of modified shale pottery sand, 12kg of zuoyun clay, 12kg of sepiolite fiber, 5kg of microcline powder, 5kg of analcite powder, Calcium nitrate 2kg, polydimethylsiloxane 0.6kg, dimethyl sulfoxide 0.5kg, wood sodium carbonate 1.2kg, dehydrated acetic acid 1kg, polyacrylate copolymer emulsion 6kg, silane waterproofing agent 2kg, antifreeze 2kg (form Two mixtures of amide and magnesium chloride, the mass ratio is 1:3), barium hydroxide coagulation regulator 3kg and triethoxybutane air-entraining agent 5kg;

[0036] Preparation of modified shale pottery sand: Take 35kg of raw material shale pottery sand and place it in a calciner, calcinate at 720°C for 2.5 hours, take out the ground powder after natural cooling, pass through a 80-mesh sieve, and then add 2.8kg of Lignin and 175kg of deionized water were stirred evenly at 85°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com