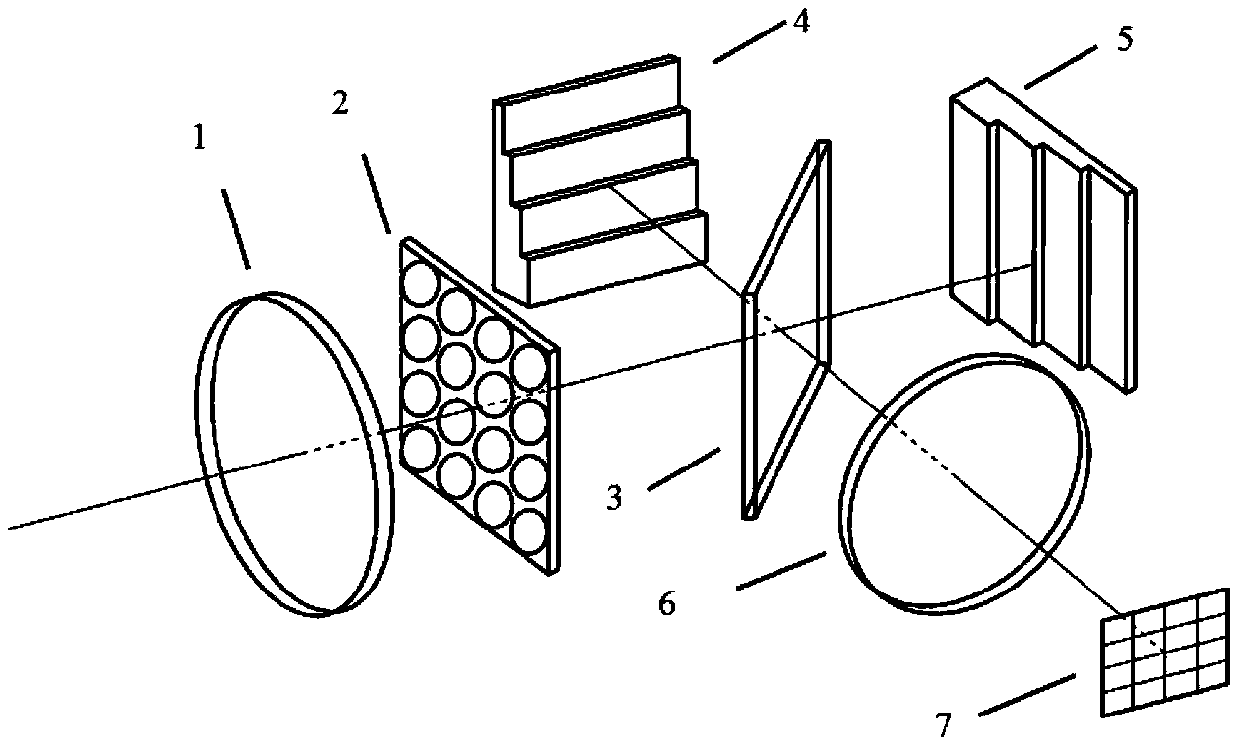

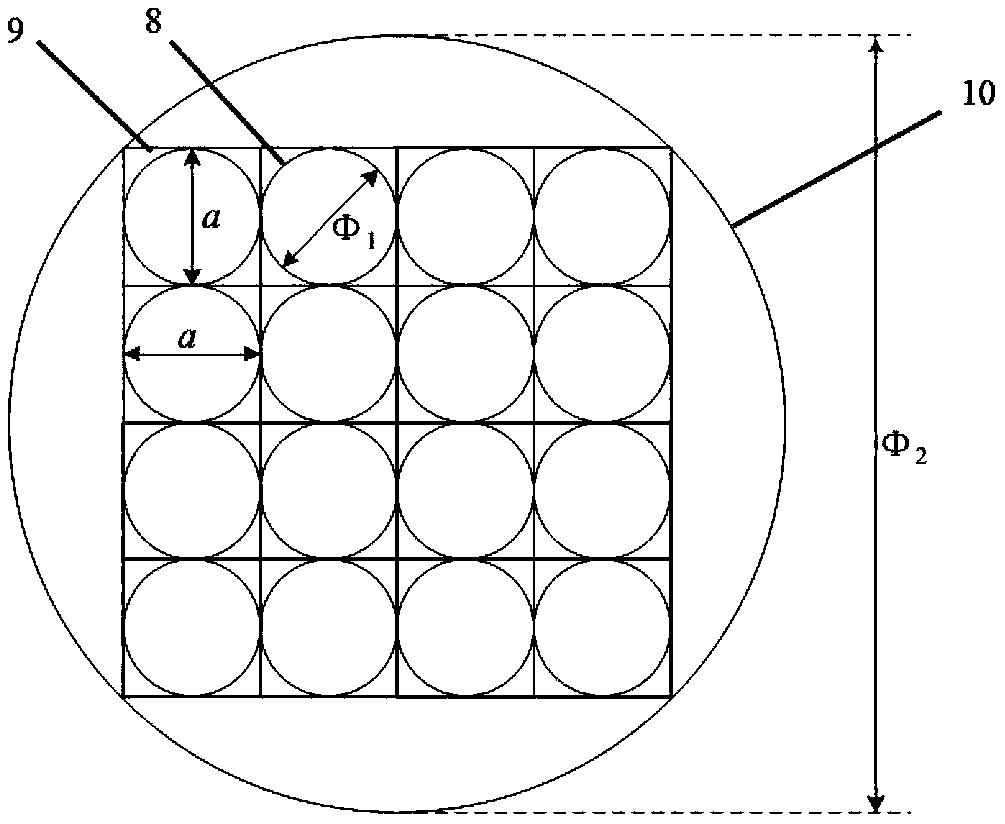

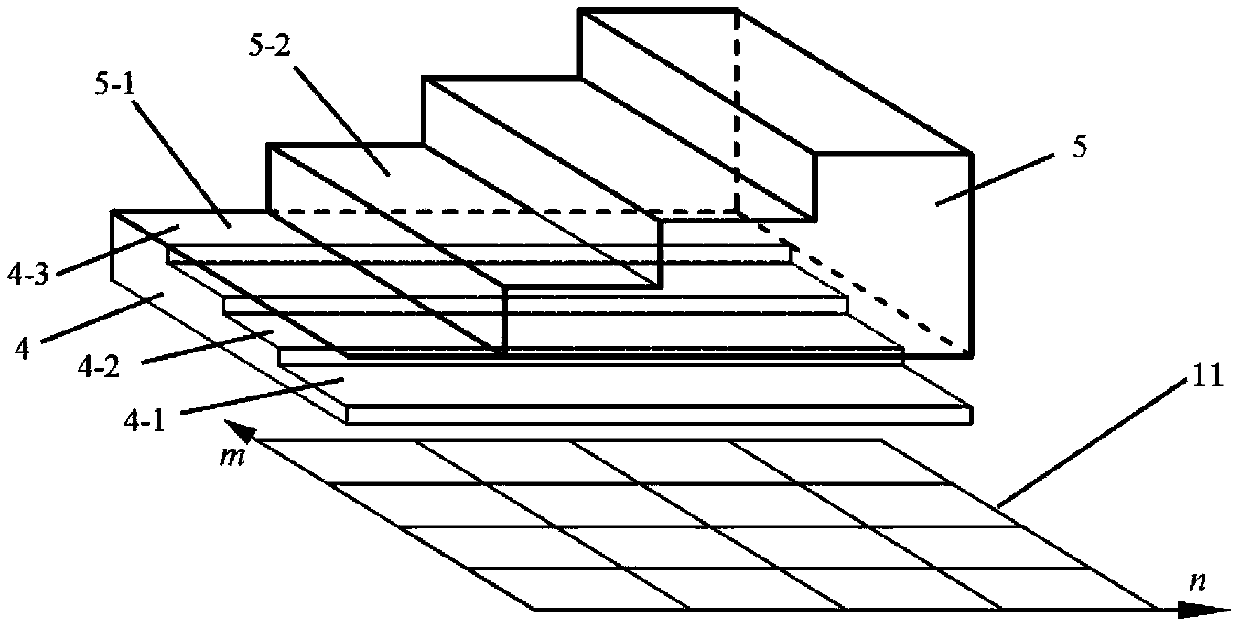

Snapshot imaging spectrometer based on stepped phase mirror and manufacturing method

A mirror and ladder technology is applied in the field of multi-channel micro-snapshot infrared interference imaging spectrometers to achieve high real-time performance, fast detection speed, and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Example 1: for Figure 8 The grid beam splitter shown in s is manufactured, and the material is a double-sided polished (100) single crystal silicon wafer with high flatness and high parallelism. Its preparation method is:

[0091] 1. Growth or evaporation of silicon dioxide and silicon nitride and other dielectric films or composite films on the cleaned double-sided polished single crystal silicon surface as a masking film;

[0092] 2. Directional photolithography to expose the side groove pattern, and remove the masking film in the side groove pattern by etching to expose the surface of the single crystal silicon. Use single crystal silicon anisotropic etching solution to etch the side groove, and the etching depth is equal to the final thickness of the beam splitter window; the shape of the side groove can also be formed by arranging multiple rectangles or squares at a certain distance apart from the figure shown in the figure.

[0093] 3. Perform a second photolit...

Embodiment 2

[0095] Embodiment 2: For both horizontal and vertical grid rib structures Figure 9 The double-sided grating beam splitter of f can be manufactured by the above method, the difference is that it is necessary to prepare a double-sided masking film, which is realized by double-sided photolithography and double-sided etching, and the upper and lower surface patterns are the same. In the first photolithographic etching, the sum of the etching depths of the upper and lower surface side grooves is the final thickness value of the beam splitter window.

Embodiment 3

[0096] Example 3: For a grid beam splitter with a structure such as Figure 8 The shape of k is made, and the material is a double-sided polished silicon wafer with high flatness and high parallelism. Its production process is as follows:

[0097] 1. Evaporating aluminum film or thermally grown silicon dioxide or evaporating silicon nitride and other metal films or dielectric films or composite films on the cleaned double-sided polished single crystal silicon surface as a masking film;

[0098] 2. Photolithography to expose the side groove pattern, and remove the masking film in the side groove pattern by etching to expose the surface of the single crystal silicon. Using ICP or RIE technology for side grooves, the corrosion depth is equal to the final thickness of the beam splitter window; besides the figure shown, the shape of the side grooves can also be formed by multiple rectangles, squares, circles, ellipses or other polygonal shapes arranged at a certain distance. to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com