Modification method for carbon felt electrode for all-vanadium redox flow batteries

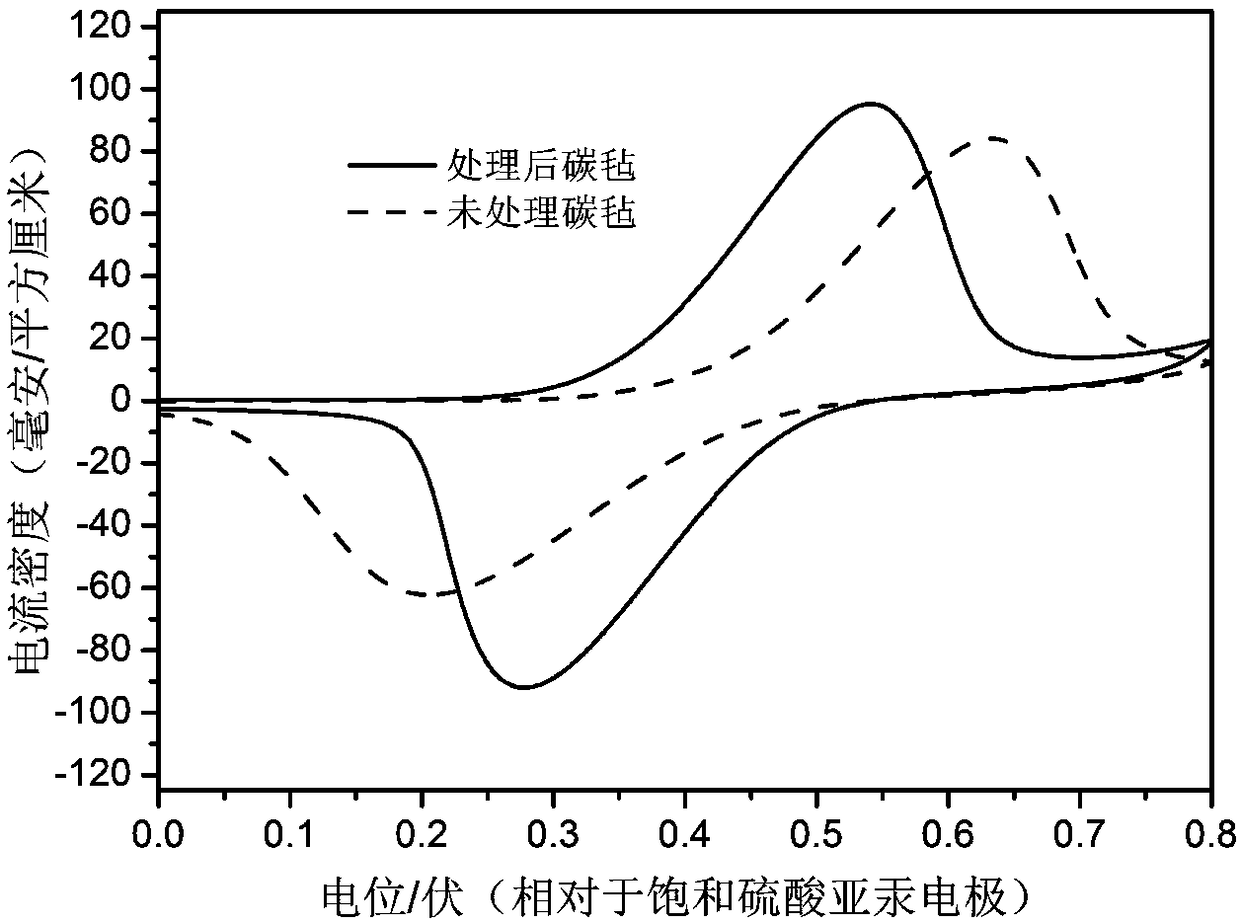

An all-vanadium redox flow battery and carbon felt technology, which is applied in battery electrodes, fuel cells, regenerative fuel cells, etc., can solve the problems that the degree of oxidation cannot be precisely controlled, the modification effect is not optimal, and the electrode materials are difficult to oxidize evenly. , to achieve the effect of improved electrochemical reversibility, uniform diffusion speed and fast diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

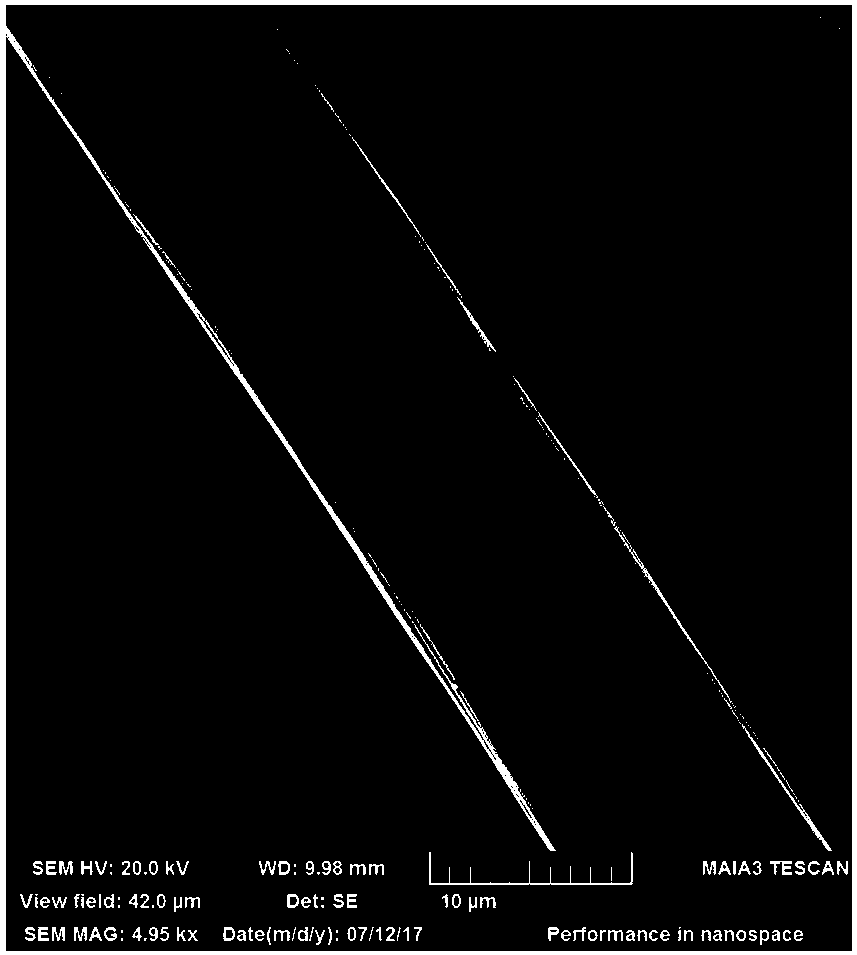

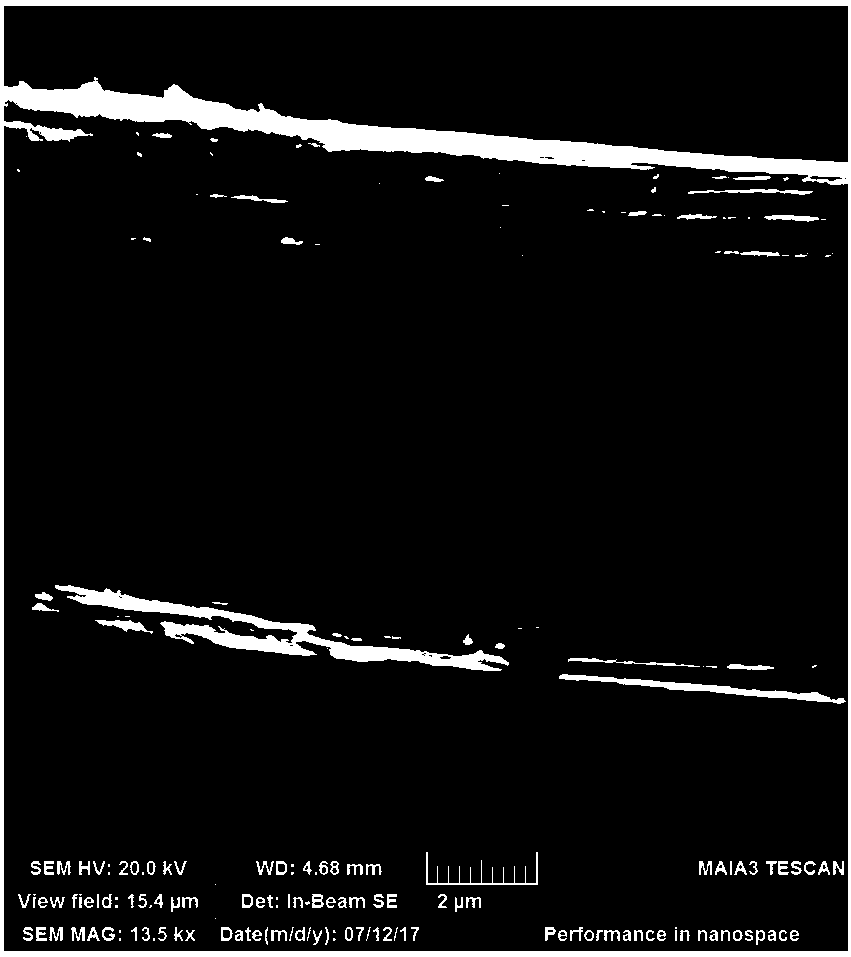

[0044] Take two carbon felts with a size of 4cm×8cm, immerse them in a beaker filled with absolute ethanol, then use an ultrasonic cleaner with a power of 5kHz to ultrasonically clean the carbon felts for 30min, take out the carbon felts and soak them in pure water for several times. Put into an oven and dry at 80°C for 12h.

[0045] Weigh the dried carbon felt to be 3.03g, so use a pipette gun to take 1.52ml of concentrated nitric acid and slowly inject it into the bottom of the inner tank of the reaction kettle, put the carbon felt into the upper opening of the glass sand core crucible, and then place the crucible Put it into the reaction kettle while avoiding direct contact between the carbon felt and concentrated nitric acid, then seal the reaction kettle and put the reaction kettle into the muffle furnace. The temperature of the furnace is raised to 200°C after 40 minutes and continues to be heated at this temperature for 300 minutes. , after cooling down to room temperat...

Embodiment 2

[0047] Take three carbon felts with a size of 4cm×8cm, immerse them in a beaker filled with absolute ethanol, and then use an ultrasonic cleaner with a power of 5kHz to ultrasonically clean the carbon felts for 30 minutes, take out the carbon felts and soak them in pure water for several times. Put into an oven and dry at 80°C for 12h.

[0048] The weight of the dried carbon felt is 4.69g, so take 4.69ml of concentrated nitric acid with a pipette gun and slowly inject it into the bottom of the inner tank of the reaction kettle, put the carbon felt into the upper opening of the glass sand core crucible, and then place the crucible Put it into the reaction kettle while avoiding direct contact between the carbon felt and concentrated nitric acid, then seal the reaction kettle and put the reaction kettle into the muffle furnace. The furnace temperature is raised to 180°C after 40 minutes and continues to heat at this temperature for 300 minutes , after cooling down to room tempera...

Embodiment 3

[0050] Take four carbon felts with a size of 4cm×8cm, immerse them in a beaker filled with absolute ethanol, and then use an ultrasonic cleaner with a power of 5kHz to ultrasonically clean the carbon felts for 30 minutes, take out the carbon felts and soak them in pure water for several times. Put into an oven and dry at 80°C for 12h.

[0051] Weigh the dried carbon felt to be 6.24g, so use a pipette gun to take 6.24ml of concentrated nitric acid and slowly inject it into the bottom of the inner tank of the reaction kettle, put the carbon felt into the upper opening of the glass sand core crucible, and then place the crucible Put it into the reaction kettle while avoiding the direct contact between the carbon felt and the concentrated nitric acid, then seal the reaction kettle and put the reaction kettle into the muffle furnace. The temperature of the furnace is raised to 150°C after 40 minutes and continues to be heated at this temperature for 300 minutes. , after cooling dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com