A magnetization-based permeation-enhancing wetting agent for improving the effect of coal seam water injection and dust reduction

A coal seam water injection and wetting agent technology, applied in the direction of dust prevention, other chemical processes, chemical instruments and methods, etc., can solve the problems of coal plasticity increase, not easy to be infiltrated, brittle weakening, etc., to improve permeability and increase infiltration Range, the effect of reducing the surface tension of substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

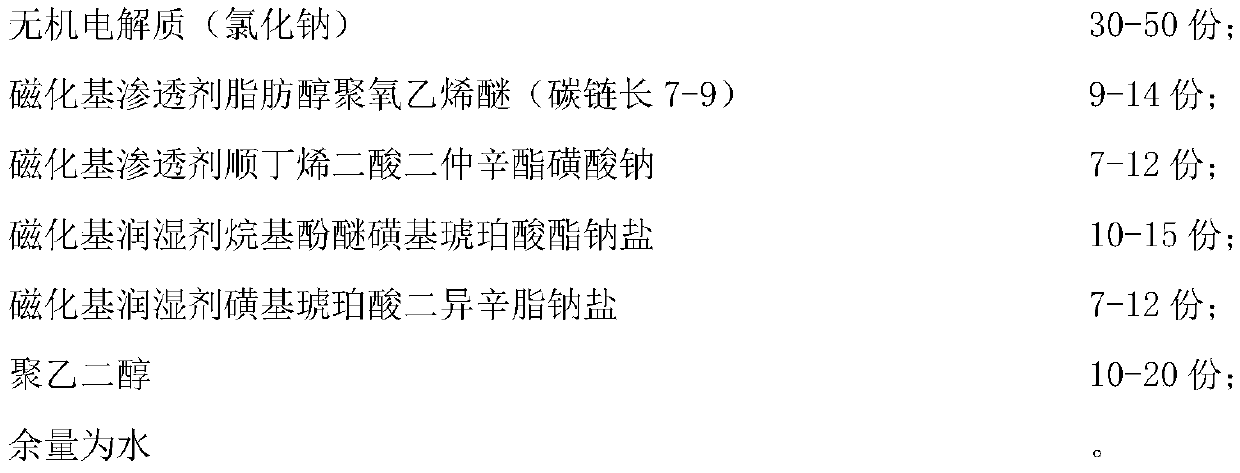

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Weigh 30 parts of sodium chloride, 9 parts of fatty alcohol polyoxyethylene ether, 12 parts of alkylphenol ether sulfosuccinate sodium salt, and 15 parts of polyethylene glycol, and prepare it as 1% by weight Additive solution, the solution flows into a special magnetized barrel at a flow rate of 2m / s, and after being magnetized in a 400mT magnetic field for 10 minutes, a magnetization-based penetration-enhancing wetting agent is obtained, which is prepared into an additive solution with a mass fraction of 0.005%, and its surface tension, Contact angle.

Embodiment 2

[0025] Embodiment 2: Take by weighing 30 parts of sodium chloride, 9 parts of dioctyl sodium sulfosuccinate, 10 parts of dioctyl sodium maleate sulfonate, and 15 parts of polyethylene glycol, and prepare the mass fraction It is a 1% additive solution. The solution flows into the special magnetization bucket of the magnetizer at a flow rate of 2m / s. After being magnetized in a 500mT magnetic field for 15 minutes, a magnetization-based wetting agent for increasing penetration is obtained, which is formulated as an additive with a mass fraction of 0.005%. solution, its surface tension and contact angle were measured.

Embodiment 3

[0026] Example 3: Weigh 9 parts of fatty alcohol polyoxyethylene ether, 9 parts of dioctyl sodium sulfosuccinate, 30 parts of sodium chloride, 15 parts of polyethylene glycol and mix them uniformly with water to form a mass fraction of 1%. The additive solution flows into the special magnetization bucket of the magnetizer at a flow rate of 2m / s, and is magnetized in a 400mT magnetic field for 10 minutes; weigh 12 parts of alkylphenol ether sulfosuccinate sodium salt, di-secondary maleic acid 10 parts of sodium octyl sulfonate, 30 parts of sodium chloride, 15 parts of polyethylene glycol and water are uniformly mixed to prepare an additive solution with a mass fraction of 1%, and flow into the special magnetization bucket of the magnetizer at a flow rate of 2m / s. Magnetize in a 500mT magnetic field for 15 minutes; uniformly mix the obtained two kinds of magnetization-based penetration-enhancing wetting agents, and prepare an additive solution with a mass fraction of 0.005% with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com