Electric heating paint and preparation method and application thereof

A technology of electrothermal coatings and functional fillers, applied in the direction of epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of short working life, low heating efficiency, uneven heating temperature of electrothermal coatings, etc., and achieve uniform heating High performance, high safety, and the effect of improving electrothermal conversion efficiency and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

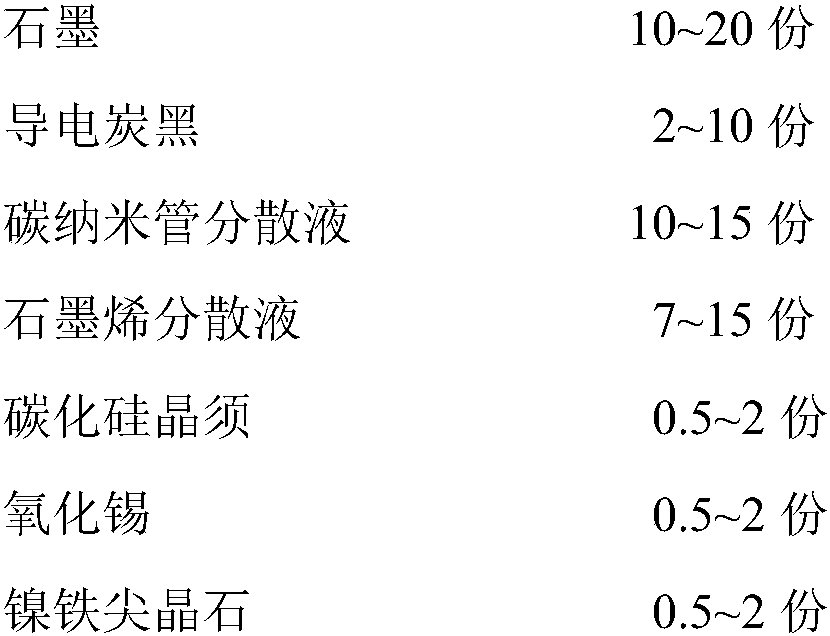

[0080] In the present embodiment, the mass fraction of each raw material consists of: 10 parts of graphite, 2 parts of conductive carbon black, 7 parts of graphene dispersion, 10 parts of carbon nanotube dispersion, 14 parts of water-based polyacrylic resin (Hanlong S120), 2 parts of water-based polyacrylic resin emulsion (Luyuan Chemical, solid content 55%), 0.5 part of tin oxide, 0.5 part of nickel-iron spinel, 0.5 part of silicon carbide whisker, 0.1 part of silane coupling agent, 1 part of polyvinylpyrrolidone, 1 part of sodium methylene bis-naphthalene sulfonate, 0.1 part of carboxymethyl cellulose, 0.1 part of carbon alcohol ether emulsion type non-silicon defoamer; 39 parts of water.

[0081] The preparation method step of a kind of novel electrothermal paint provided by the invention is as follows:

[0082] (1) Preparation of resin colloid

[0083] Weigh the water-based resin and water-based resin emulsion by weight, mix and stir with solvent water, the stirring tempe...

Embodiment 2

[0088] In the present embodiment, the mass fraction of each raw material consists of: 20 parts of graphite, 10 parts of conductive carbon black, 15 parts of graphene dispersion, 15 parts of carbon nanotube dispersion, 27 parts of water-based polyacrylic resin (Hanlong S120), 3 parts of water-based polyacrylic resin emulsion (Luyuan Chemical, solid content 55%), 2 parts of tin oxide, 2 parts of nickel-iron spinel, 2 parts of silicon carbide whiskers, 0.5 part of silane coupling agent, 3 parts of polyvinylpyrrolidone, 3 parts of sodium methylene bis-naphthalene sulfonate, 1 part of carboxymethyl cellulose, 0.5 parts of carbon alcohol ether emulsion type non-silicon defoamer; 39 parts of water.

[0089] The preparation method step of a kind of novel electrothermal paint provided by the invention is as follows:

[0090] (1) Preparation of resin colloid

[0091] Weigh the water-based resin and water-based resin emulsion by weight, mix and stir with the solvent water, the stirring ...

Embodiment 3

[0096] In the present embodiment, the mass fraction of each raw material consists of: 20 parts of graphite, 6 parts of conductive carbon black, 10 parts of graphene dispersion, 13 parts of carbon nanotube dispersion, 17 parts of water-based polyacrylic resin (Hanlong S120), 2.25 parts of water-based polyacrylic resin emulsion (Luyuan Chemical, solid content 55%), 1 part of tin oxide, 0.5 part of nickel-iron spinel, 1 part of silicon carbide whisker, 0.5 part of silane coupling agent, 2 parts of polyvinylpyrrolidone, 2.5 parts of sodium methylene bis-naphthalene sulfonate, 1 part of carboxymethyl cellulose, 0.5 parts of carbon alcohol ether emulsion type non-silicon defoamer; 39 parts of water.

[0097] The preparation method step of a kind of novel electrothermal paint provided by the invention is as follows:

[0098] (1) Preparation of resin colloid

[0099] Weigh the water-based resin and water-based resin emulsion by weight, mix and stir with the solvent water, the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com