A kind of powder-free cold water instant micro-dry medium and its preparation method

A drying medium and culture medium technology, which is applied in the field of powder-free cold water instant micro-drying medium and preparation, can solve the problems of inaccurate test results, pollution of operating space, slow absorption and diffusion, etc., and achieve low cleanliness and small volume , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the preparation of powder-free dry medium

[0042] 1) 20g of tryptone, 10g of yeast extract, 4g of glucose, 5g of microcrystalline cellulose, and 80g of carrageenan, mixed by ball milling for 2 to 3 hours to make them uniform, to obtain dry medium powder;

[0043] 2) Add 2g of polyethylene glycol to 20ml of methanol and stir while fully dissolving and mixing. Weigh 1.5g of medium dry powder and add it to the above solution. Take about 2ml of polyethylene terephthalate (PET) with a diameter of 50mm. ) Blister test piece, hot air drying;

[0044] 3) After covering the polypropylene (PP) film, 15KGy irradiation sterilization, that is, the powder-free cold water instant micro-dry medium of the present invention.

Embodiment 2

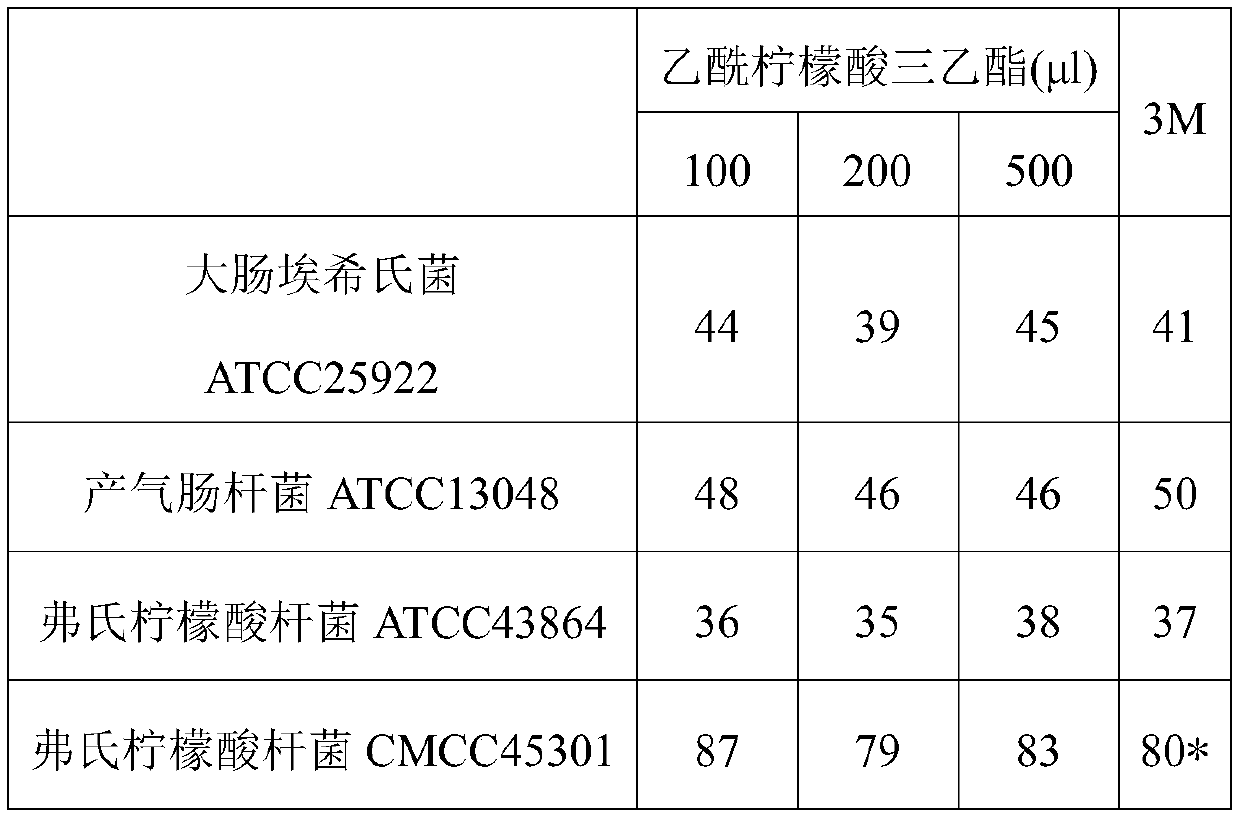

[0045] Embodiment 2, the effect evaluation of the culture medium that acetyl triethyl citrate plasticizer is made

[0046] 1) Tryptone 5g, yeast extract powder 2.5g, glucose 1g and carrageenan 34g (more than 80 mesh), ball mill and mix evenly;

[0047] 2) Add different amounts of acetyl triethyl citrate to 20ml of methanol, then add 2g of polyethylene glycol, and after fully dissolving, add 1.5g of ball-milled dry powder to disperse evenly;

[0048] 3) Take 2ml and make it into a test piece and dry it;

[0049] 4) Sterilize by irradiation with cobalt 60 at a dose of 15KGy.

[0050] Escherichia coli ATCC25922, Enterobacter aerogenes ATCC13048, Citrobacter freundii ATCC43864, and Enterobacter cloacae CMCC45301 were cultured in the brain heart infusion at 36±1°C for 16-18 hours, and the enrichment solution was shaken with sterile saline Gradually dilute to about 100 CFU / ml, and finally add 1ml of 0.05% sterile TTC solution and mix well. Take 1ml and add it to the center of the...

Embodiment 3

[0055] Embodiment 3, the impact of surfactant Tween on the dispersion effect of dry medium

[0056] 1) Tryptone 5g, yeast extract 2.5g, glucose 1g, guar gum 41g, carrageenan 10g, ball mill and mix;

[0057] 2) Add 500ul of acetyl triethyl citrate to 20ml of methanol, then add 2g of polyethylene glycol to fully dissolve into a transparent solution, take 1.8g of the mixed dry powder and add it to the above solution and mix well;

[0058] 3) Take 2ml of one part and add it directly to a PET blister box with a diameter of 50mm, and heat it at 60°C until it is completely dry; add 200μl Tween 80 to the other part, mix well, take 2ml and add it to a PET blister box with a diameter of 50mm, 60 °C until completely dry. Observe the appearance of the medium formed after drying.

[0059] The results showed that the dried culture medium without adding Tween 80 was unevenly dispersed, in the shape of gully, and partly gathered together. The culture medium formed after adding Tween 80 aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com